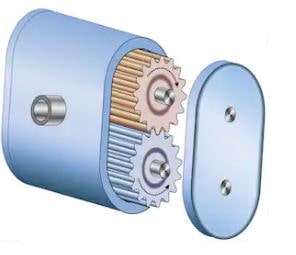

Gear Pump or Oil Pump

Gear Pump:

A gear pump is a device or equipment used to pump the oil to lubricate the moving parts, this pump contains two gears inside a closed casing, and the gears present inside it moves opposite to each other due to they are intermeshed. Gear pump only supplies the oil to parts it does not pumps the oil in reverse direction, due to the gears present init moves only in one direction.

Supply of oil through gear pump increases the flow rate and pure. this also increases the supply pressure.

And this gear pump contains only one inlet and one outlet.

With the help of this pump clean and lubricating oils are pumped and there is also possible to supply semi fluids by this gear pump method.

In this gear pump system there is not possible in reverse flow of fluid due the gears constantly rotates only in one direction.

This gear pump used to produce around 200 atmospheric pressure and supplies the lubricating oil’s for further function.

Advantages:

- Thick oils can be supplied by this method.

- It can produce high pressure.

- This has no vibrations or sounds developed init.

- The discharge of lubricant is according to the speed of the pump.

Disadvantages:

- There is no possible in pumping emulsions.

- The pump may get damaged if work under a closed valve.

Please Subscribe! and Don’t forget to Follow us on Facebook, Twitter, Linkedin, Instagram and Google Plus.