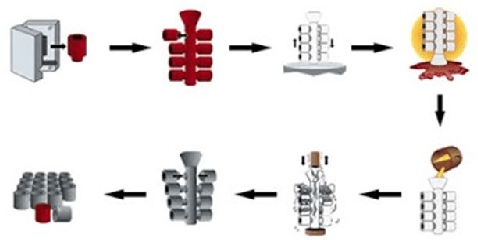

Investment casting process, Advantages, disadvantages, and Applications

Investment casting process: The investment casting process is also called a precision casting process. this type of casting produces high accuracy dimensions. investment casting process used in many industries. In this casting process, the molten metal is poured into a mold. to develop an object from this process the pattern is made by metals like steel, which is an accurate and clear surface finish. The mold is obtained after solidification is done. to make the process of final casting we need to make a master mold, this is obtained by making with different acids like phosphoric, silicate etc. After obtaining a final product for casting, the mold must be heated to melt the master mold and cooled. after getting into cooled the final product is obtained.

Advantages:

*) By this casting process, we can obtain a high tolerance.

*) The product made by this process does not need any finishing.

*) We can produce multiple castings at a time.

Disadvantages:

*) This type of casting is not useful to heavy weight products.

*) Cost of the manufacturing method is high.

*) Care should be taken at the time of casting.

Applications:

This type of process is mostly used in large capital industries, due to the process required high investment.

*) For making Jewelry.

*) Computer parts, Used in industries like aerospace, to manufacture turbine blades etc..