Water Jet Machining – Working Principle, Advantages and Disadvantages

Water Jet Machining?

Water jet machine is a type of cutting machine. In this type of machine water is used as medium. In this machine water is supplied through different parts and enters into the nozzle, and passes out with high pressure and strikes the metal to cut or remove the extra material. This is one of the methods highly used in many manufacturing industries. this type of machining process work with accurate and faster. This method of operation has different uses and advantages. There are two types of water jet machines they are Water jet machine and Abrasive water jet machine, with the help of water jet machine we can cut only non-metals but by using abrasive water jet machine we can cut metals which are strong and hard. Here abrasive water jet machine working is same as water jet but there is an additional abrasive particles used in it to cut hard and strong metals. The detailed Explanation about Water jet machine and Abrasive water jet machine is as follows:

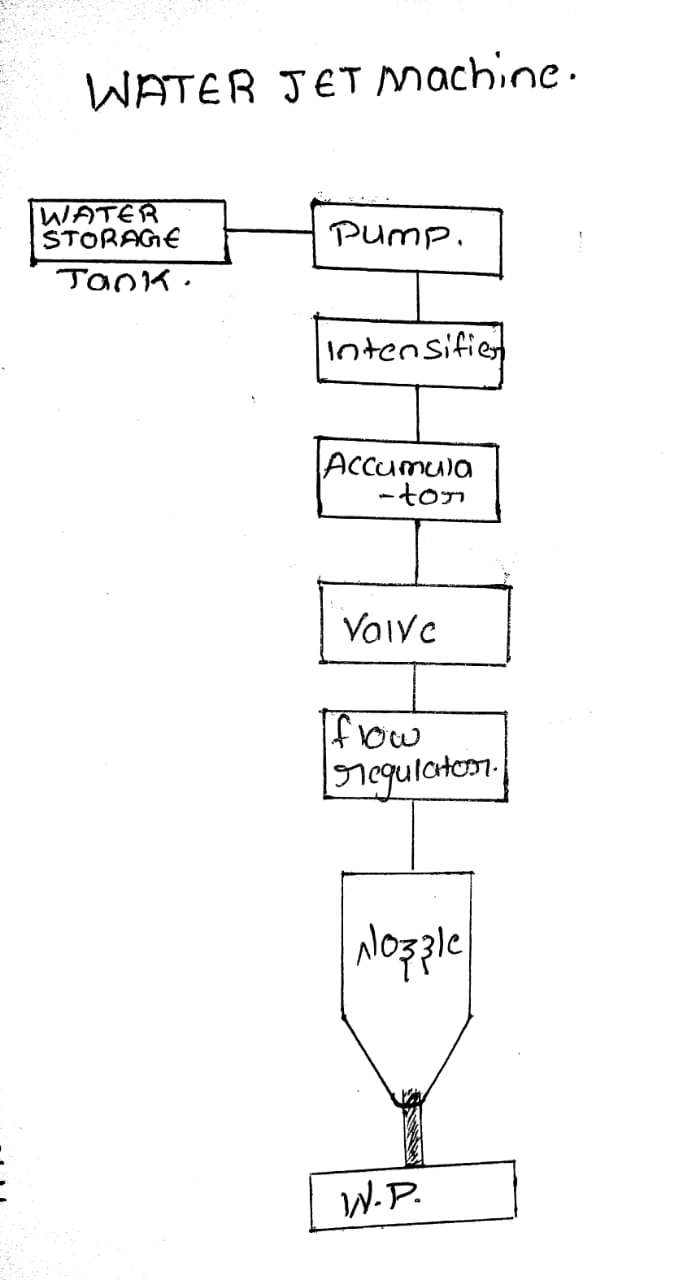

Working of Water Jet Machining:

When the water from a storage tank is lifted by the help of the pump and supply to Intensifier their water gets highly pressurized and this pressurized water used to enter in to the accumulator where water is used to store in it, and further this is supplied to valves, there it gets controlled by valves to pass required quantity, required pressure and from there it enters in to flow regulators to get into a required direction and enters into a nozzle, this nozzle creates a high-velocity outlet of water and helps to strikes the material to cut/remove.

Parts of Water Jet Machining:

- Storage Tank

- Pump

- Intensifier

- Accumulator

- Valves

- Regulators

- Nozzle

Storage tank:

Storage tank used to store the required water that need for machining process.

Pump:

This is used to supply the water from storage tank to intensifier with normal pressure.

Intensifier:

This is used to increase the pressure of water.

Accumulator:

This helps to store the high-pressure water.

Valves:

It controls the water supply. like pressure, quantity etc..

Regulators:

It Regulates the water flow into the nozzle.

Nozzle:

This increases the velocity of water enters into it and make directions to cut.

Advantages of water jet machining:

- This has highly accurate cutting action.

- Cleaning the work piece is automatic.

- High Tolerance can obtain by this process.

- Working medium is water, highly available in nature.

Disadvantages of water jet machining:

- Water jet machine cannot cut metals.

- Cost is high.

Abrasive Water Jet Machining:

An abrasive jet machine works the same as water jet machine but, In Abrasive jet machine, it uses Abrasive particles. which is mixed in high-pressure water to increases the cutting property of the fluid. General abrasive particles are garnet,silicon etc.This can cut different types of metals and used in different industries. This increases the depth of cut. Many industries use these machines to work with efficient and to increase production.

Working of Abrasive Water Jet Machining:

This is the same as water jet machining, Water from the tank is supplied to the intensifier by the help of a hydraulic pump, their water increases to high pressure.this high-pressure water used to pass through orifice after getting into orifice abrasive particles are used to mix with water and further sent to the valve to supply required quantity into the nozzle, this increases the velocity of abrasive water and makes to strike the metal for cutting/removing.

Advantages of Abrasive Water Jet Machining:

- This can cut any type of materials.

- High accuracy can obtain.

- The depth of cut can increased by this method.

- The operation is smooth.

- Mechanical properties changes do not occur in the working process.

- Surface finish is high.

Disadvantages of Abrasive Water Jet Machining:

- Cost is high.

- It removes low metal rate.

- It is difficult to machine thick metals.