Optiz Coding System:

Optiz is a coding system that used to identify the products Dimensions, Accuracy, Material, Original shape of raw material etc.Optiz is the one of widely used coding classification method to specify the design of the product to manufacturing.

This method is designed and developed by H. Optiz.

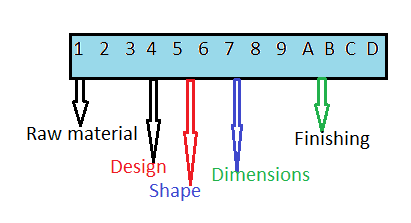

For finding the data of product it uses nine numbers which is 123456789 and for any additional requirement it uses four more digits like ABCD.

All these codes are used to divide into different groups and used to find different properties.

By using five numbers 12345 which are known as form code used to identify the geometrical data and another four digits 6789 are known as supplementary codes to

get the find the manufacturing data, and for the further process, we use ABCD called secondary codes to get the information related to the operation process.

Optiz system is used to collect the required data from manufacturing unit and from design of product. To collect the complete information related to a product the given digits is divided to specify the products details like Raw material, Shape, Dimensions, Material, Machining process etc.

To identifying the complete information related to product from raw material to manufacturing it includes many steps like design, cutting, finishing etc. Optiz used to calculate all the information and identify the errors related to the product.

Advantages of optiz code system:

This is a type of protecting system used in coding system.

It gives about a complete classification in this working system

This type of system is useful in any type of works like machining, inspection etc.

This system used to verify total manufacturing process

Disadvantages of optiz code system:

Every separate process includes a different codes, it does not contains a single common code in it.

This is not so useful at different types of products in a manufacturing unit.