Industrial Robots:

In this article, we are going to discuss about industrial robots. There is not much difference between a robot and industrial robots. Industrial robots are used to decrease the work stress and helps to increase the work efficiency and production rate in manufacturing sector.

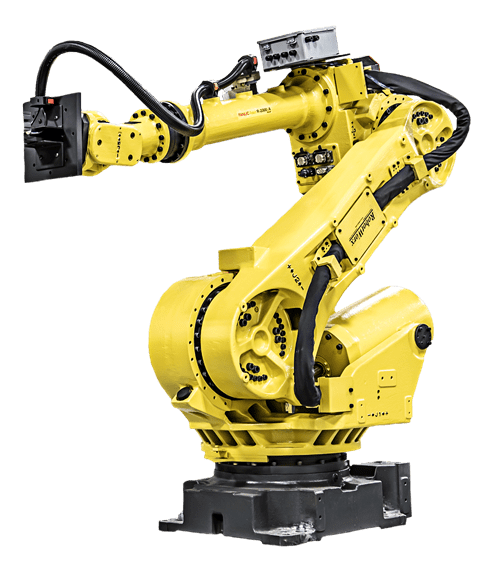

In Industrial Robots they consist of robotic arms to work in different places and used to work under different conditions where humans cannot work.

Most of the industrial robots are automatic, they used to work according to the program designed. This type of robots is used for repeatable works and continue working without brake.

Manual type robots are controlled with the help of humans.

Most of the industrial robots are used for Assembling, Transporting, Welding, Cutting, Handling heavy equipment, etc.

Most of the industries use robots to work under risk conditions, by replacing humans with robots we are free from risk. and they work efficiently and accurately under high temperatures or cold conditions.

There are many types of industrial robots frequently used for fast production rate, quality work, accuracy, inspections, etc.

This type of robots reduces manpower and increases the safety.

Industrial robots are more flexible and highly accurate, they reduce human errors and save time.

Industrial robots are used in every manufacturing field from Aerospace to Household applications.

There are different industrial robots like SCARA Robots, Cartesian Robots, Six axis robots etc..

Industrial robots used for crucial and harmful works like Painting, Material Handling, Welding, Loading, and Unloading, etc..

Weldings like spot welding and carrying complex objects from one place to another place is done easily by industrial robots.

Some of the harmful coatings are harmful to humans this type of works can be done by robots easily with high accuracy.