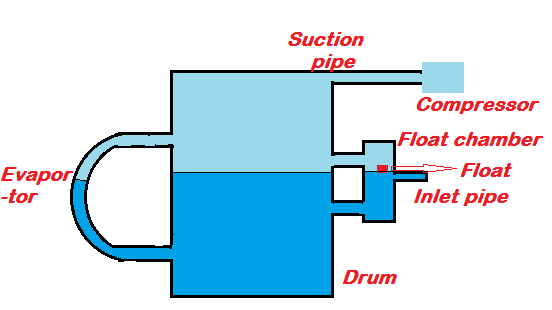

Flooded Evaporator:

The flooded evaporator is a device which is used to control and maintain the required level of liquid refrigerant in evaporator and this evaporator is used to store the liquid refrigerant with the help of a drum. Flooded evaporator helps to run the refrigeration system cleanly by maintaining the constant liquid level.

Main parts of a flooded evaporator:

Drum:

This is used as the storage tank and supply the required vapour refrigerant to the compressor.

Evaporator:

This is used to find the level of the liquid refrigerant.

Suction pipe:

This is used to supply the vapour of refrigerant into the compressor.

Compressor:

This is used to compress the vapour refrigerant.

Float chamber:

It is used to find the level of liquid refrigerant and helps to supply the required refrigerant to the drum with the help of float arranged in it.

Float:

This is used to supply and stop the liquid refrigerant enter into the drum.

Inlet pipe:

This is used to supply the required refrigerant and controls with the help of control valve.

Working of a flooded Evaporator:

The flooded evaporator consists of a drum which is placed as shown in the figure, the drum is used to store the liquid refrigerant by maintaining the required level of liquid refrigerant in the evaporator. The flooded evaporator drum is also used to divide the liquid refrigerant from vapour refrigerant.

The liquid refrigerant is stored in the bottom of the drum and vapour refrigerant flows to the compressor through the suction pipe shown in the figure.

Due to the supply of heat to the liquid refrigerant, it converts into vapourization and moves over the top of the drum and enters into the suction pipe for further compression process. due to vaporization of the liquid refrigerant, the level in the drum gets decreased by this the float chamber attached to it also decreases the level of the liquid refrigerant, by this, the float arranged in the chamber get decreased and helps to supply the liquid refrigerant in to the float chamber and further transferred into the drum after increasing the level of fluid the float arranged in the chamber reaches the supply line of the liquid refrigerant and stop the supply.