Automatic Lubrication System – Types and Components

⏩ Tables of Content:

- Automatic Lubrication System

- Components of automatic lubrication system

- Types Automatic Lubrication System

- Advantages of Automatic Lubrication System

Automatic Lubrication System:

A lubrication system is used to increase the operational performance in automobiles or industrial machinery. by lubricating the parts the process gets smoother and can avoid early damages through wearing, overheating, surface fatigue, etc. There are two types of systems available:

1. Oil System &

2. Grease System

The functionality of Oil and Grease is similar but according to the requirement they are used.

OIL SYSTEM:

The oil system is generally used in Milling Machines, Automobile Engines, etc.Oil

is a liquid lubricant that is generally used to lubricate the engine

parts which decrease the temperature and helps to run the engine

smoothly and it also helps from wearing the parts early which avoids

replacements and maintenance

GREASE SYSTEM:

Grease System is used in heavy-duty machinery like Heavy Vehicles, Mining Machines, Construction Machinery, etc. Grease is a semisolid lubricant that is mostly used in heavy machinery parts like bearings, couplings, heavy cables, etc.

Components of automatic lubrication system:

Controller:

It controls the system when to activate. when lubrication is required the controller gets activated and guides for a further distribution process.

Pump:

The pump is used to supply the required lubrication to different parts.

injectors:

Injector helps to supply the lubricant to required points.

Feed Lines:

These are the points that make a contact with injectors to receive the lubricant.

Types Automatic Lubrication System:

Single Line Progressive Automatic Lubrication System:

A single line progressive system uses lubricant to flow through individual cycle for metering valves and valve assemblies.

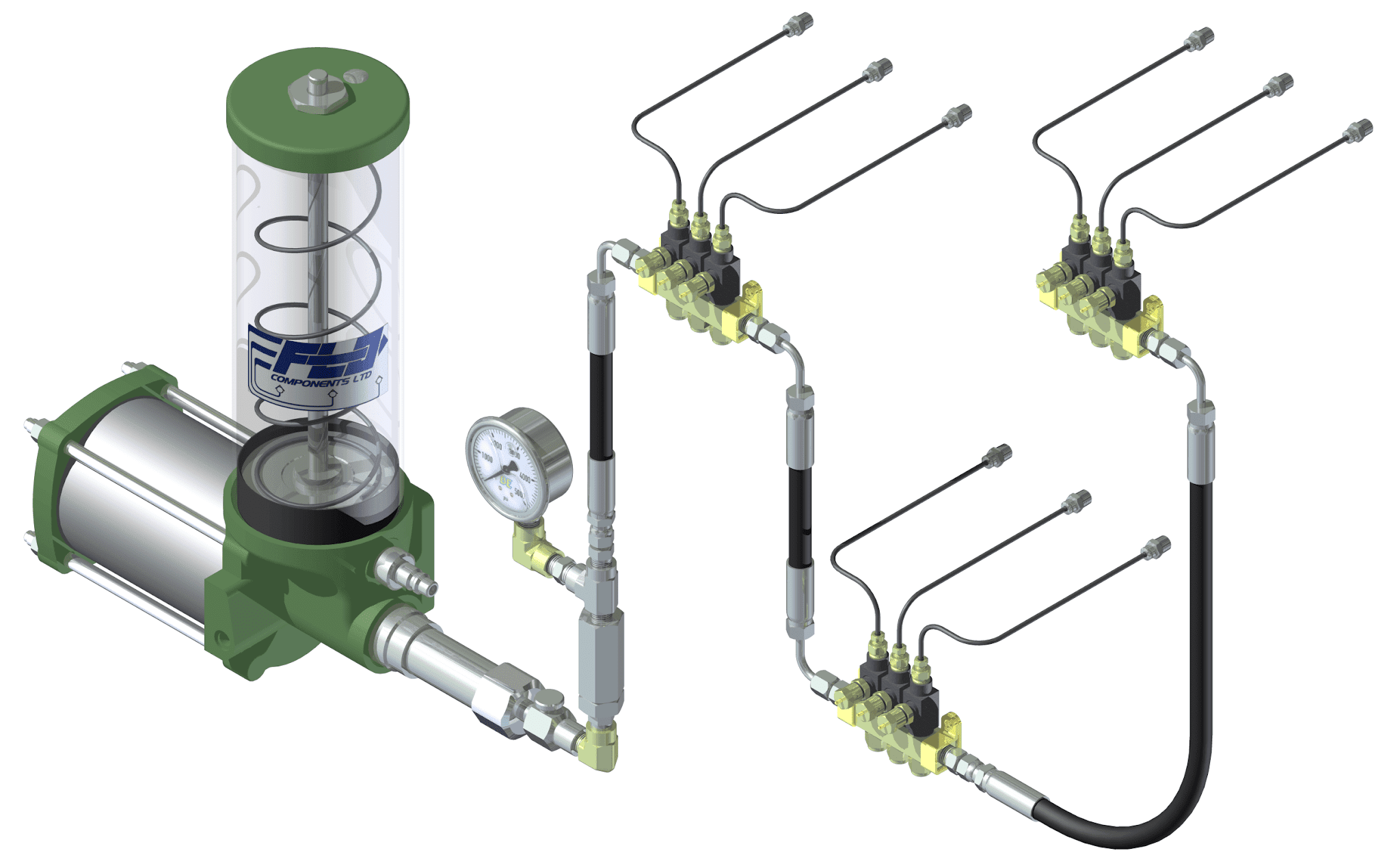

Single line parallel:

A single line parallel system can service a single machine, different points on a single machine or even on separate machines.

Image Source: Link

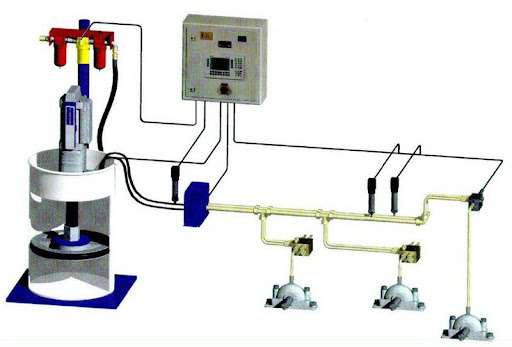

Dual Line Parallel Automatic Lubrication System:

A

dual line parallel system is similar to the single line parallel system

in that it uses hydraulic pressure to operate this system

Image Source: Link

Multi point direct lubricator:

It helps to-dispense a fixed amount of lubricant to each individual lubrication point

Advantages of Automatic Lubrication System:

- It is more effective than the manual type.

- It is safer to use.

- It is more consistent.

- More accurate than manual and can avoid excess amount of lubricant.

- It is more productive.