What is Gear Train?

A gear train is a mechanical system comprising two or more gears that make contact with each other to transmit power from one shaft to another. These gears are used to convert rotational motion, adjust torque, and change the direction of rotation.

Types of Gear Train?

Gear trains are mechanical systems used to transmit power and motion between rotating shafts through intermeshing gears. There are several types of gear trains:

- Simple Gear Train: In a simple gear train, gears are connected in series along parallel shafts, providing a basic means of speed and torque conversion.

- Compound Gear Train: Compound gear trains combine multiple gears on a common shaft to achieve a wider range of speed and torque ratios, enhancing versatility.

- Reverted Gear Train: A reverted gear train features gears in a compound arrangement where the axes of the first and last gears coincide, creating a unique mechanical configuration.

- Epicyclic Gear Train: Epicyclic gear trains involve one gear revolving around another, resulting in complex motion patterns. They are used in various applications, including planetary gear systems.

- Differential Gear Train: Differential gear trains are found in vehicles and machinery to distribute power to multiple outputs while allowing them to rotate at different speeds, as in the case of a vehicle’s differential.

These diverse gear train types cater to specific applications, offering solutions for speed adjustment, torque multiplication, and power distribution in mechanical systems.

Simple Gear Train:

A simple gear train is a fundamental type of gear arrangement in which two or more gears are connected in series, each mounted on its own shaft. These shafts run in parallel, and the gears mesh with one another to transmit motion and power. Here’s more detail about simple gear trains:

Description:

- In a simple gear train, gears are aligned on parallel shafts, and their teeth mesh to transmit rotational motion.

- The first gear, known as the driver gear, imparts motion to the second gear, called the driven gear, and so on if there are more gears in the train.

- The gear ratio, which determines the speed and torque relationship between the driver and driven gears, is calculated based on the gear sizes.

Applications Simple Gear Train:

- Simple gear trains find extensive use in various mechanical systems, from clocks and watches to bicycles and manual transmissions in vehicles.

- They are employed wherever a straightforward and predictable speed or torque conversion is needed between two parallel shafts.

Advantages Simple Gear Train:

- Simplicity: Simple gear trains are easy to understand, design, and maintain.

- Cost-Effectiveness: They are typically less expensive to manufacture than more complex gear arrangements.

- Efficient Power Transfer: They offer efficient power transmission with minimal losses when properly lubricated.

Disadvantages Simple Gear Train:

- Limited Gear Ratio Range: Simple gear trains have a limited ability to change the speed and torque significantly.

- Single Path of Power: Power flows in a single path from the driver gear to the driven gear, limiting flexibility in power distribution.

- Noise: At higher speeds, gear meshing can produce noise and vibration.

Examples of Simple Gear Train:

- Bicycle Gear System: The gear system on a bicycle typically includes a simple gear train, allowing the rider to change gears and adapt to different terrain and riding conditions.

- Clock Mechanisms: Many clocks and watches use simple gear trains to regulate the movement of their hands and keep accurate time.

- Manual Transmission: In a manual transmission of a vehicle, a simple gear train is employed to select and engage various gear ratios for changing the vehicle’s speed.

In summary, the simplicity and reliability of simple gear trains make them suitable for a wide range of applications where basic speed and torque conversion are required. They are foundational in the field of mechanical engineering and have been used for centuries in various mechanical devices and systems.

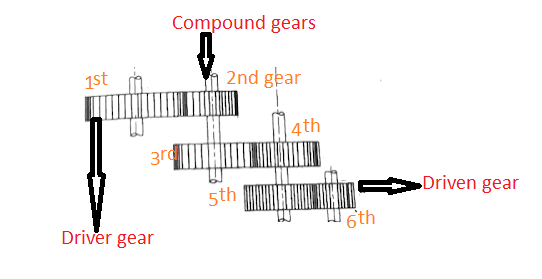

Compound Gear Train:

A compound gear train is a type of gear arrangement in which two or more gears are mounted on a common shaft or shafts, allowing for a wider range of speed and torque ratios compared to a simple gear train. This arrangement is often used in various mechanical systems and machinery. Here are the key details about compound gear trains:

Description:

- In a compound gear train, multiple gears are connected on one or more common shafts.

- The gears can be of different sizes and have different numbers of teeth, enabling complex speed and torque relationships.

- Compound gear trains consist of both driver gears (input) and driven gears (output), with power transmitted through the meshing of their teeth.

Applications of Compound Gear Train:

- Compound gear trains are commonly used in mechanical and industrial systems where precise control of speed and torque is essential.

- They find applications in automotive transmissions, machine tools, conveyor systems, and many other machinery setups requiring a versatile power transmission mechanism.

Advantages of Compound Gear Train

- Versatility: Compound gear trains allow for a broader range of speed and torque ratios compared to simple gear trains.

- Precision: They enable fine adjustments and control over mechanical systems due to their flexibility.

- Increased Efficiency: These gear trains can distribute power more efficiently across multiple stages.

Disadvantages of Compound Gear Train

- Complexity: Compound gear trains are more intricate and require careful design and maintenance.

- Higher Manufacturing Costs: The presence of multiple gears on common shafts can increase manufacturing costs.

- Potential for Increased Friction: With multiple gear meshes, there is an increased possibility of energy losses due to friction and wear.

Examples of Compound Gear Train:

- Automotive Transmissions: Modern automatic and manual transmissions in vehicles often employ compound gear trains to provide various speed options for the driver.

- Machine Tools: Compound gear trains are used in machine tools like lathes and milling machines to control the rotation speed and movement of cutting tools.

- Conveyor Systems: Industrial conveyor systems use compound gear trains to regulate the speed and torque necessary for transporting materials efficiently.

In summary, compound gear trains are essential components in mechanical systems where a wide range of speed and torque adjustments are required. Their ability to provide precision and control makes them invaluable in various industrial and automotive applications.

Reverted Gear Train:

A reverted gear train is a specific type of compound gear train characterized by the arrangement of gears where the axes of the first and last gears coincide. This unique configuration provides distinct advantages and applications in mechanical systems. Here are the key details about reverted gear trains:

Description:

- In a reverted gear train, two gears are positioned on parallel shafts, and a third gear is idler or intermediate gear that connects them.

- The first and last gears share a common axis, and the idler gear meshes with both the driver and driven gears.

- This arrangement results in the first and last gears rotating in opposite directions.

Applications Reverted Gear Train:

- Reverted gear trains are used in specific engineering applications where the reversal of direction is required.

- Common applications include reversing the direction of motion in machinery or devices like printing presses, where paper needs to change direction without stopping the printing process.

Advantages Reverted Gear Train:

- Direction Reversal: The primary advantage of a reverted gear train is its ability to reverse the direction of rotation, which is often necessary in certain industrial processes.

- Compact Design: This type of gear train can be compact and space-efficient due to its specialized configuration.

Disadvantages Reverted Gear Train:

- Limited Use: Reverted gear trains have a specific function, and their application is relatively narrow compared to other types of gear trains.

- Increased Complexity: While the concept is straightforward, the implementation of reverted gear trains can involve additional components and complexity in design.

Examples of Reverted Gear Train:

- Printing Presses: Reverted gear trains are commonly found in printing presses to change the direction of paper feed, allowing continuous printing on both sides of the paper without stopping.

- Textile Machinery: In textile machinery, reverted gear trains can be used to reverse the motion of spinning or weaving equipment when necessary.

In summary, a reverted gear train serves a specialized function in mechanical systems, particularly when there is a need to reverse the direction of motion without interrupting a continuous process. Its unique design enables this reversal, making it a valuable component in specific industrial applications.

Epicyclic Gear Train:

An epicyclic gear train, also known as a planetary gear train, is a complex and versatile gear arrangement used in various mechanical systems to achieve specific motion patterns and speed variations. It consists of several gears arranged in a way that one or more gears rotate around a central sun gear. Here are the key details about epicyclic gear trains:

Description:

- In an epicyclic gear train, there are typically three main components: a central sun gear, a planet carrier that holds one or more planet gears, and an outer ring gear.

- The planet gears mesh with both the sun gear and the ring gear, allowing them to rotate on their own axes while also orbiting around the sun gear.

- Depending on the configuration, power can be input, output, or controlled through any of these components, allowing for a wide range of applications and motion patterns.

Applications of Epicyclic Gear Train:

- Epicyclic gear trains are used in various engineering applications where specific motion control, speed adjustment, or torque multiplication is required.

- Common applications include automatic transmissions in vehicles, robotics, aerospace systems, and industrial machinery.

Advantages of Epicyclic Gear Train:

- Compactness: Epicyclic gear trains are known for their compact and space-efficient design, making them suitable for applications with limited space.

- Versatility: They provide versatile control over rotational motion, allowing for various speed ratios and motion patterns.

- Load Distribution: Multiple planet gears evenly distribute the load, reducing wear and increasing durability.

Disadvantages of Epicyclic Gear Train:

- Complexity: Epicyclic gear trains can be more complex to design, manufacture, and maintain compared to simpler gear arrangements.

- Efficiency Losses: Due to the multiple gear meshes, there may be some energy losses through friction and wear.

- Limited High-Torque Applications: In very high-torque applications, the relatively small planet gears may not be sufficient, and additional stages may be needed.

Examples of Epicyclic Gear Train:

- Automotive Transmissions: Epicyclic gear trains are commonly used in automatic transmissions to control gear changes and torque distribution between the engine and wheels.

- Robotics: Robotics often employ planetary gear systems to achieve precise and controlled movement in robotic joints and limbs.

- Aerospace Systems: Epicyclic gear trains can be found in aerospace applications for tasks such as adjusting flaps and controlling landing gear.

In summary, epicyclic gear trains offer a versatile means of controlling motion and power distribution in various mechanical systems. Their compact design and flexibility make them valuable components in engineering applications that require precise speed control, direction changes, or torque multiplication.

Applications of Gear Trains:

- Gear trains are found in numerous applications, including automobiles, bicycles, industrial machinery, watches, and more.

- They are critical components in the transmission systems of vehicles, ensuring efficient power transfer and speed adjustment.

- Gear trains are also used in manufacturing processes, robotics, and various mechanical systems where motion control is essential.

Advantages of Gear Trains:

- Efficient transmission of power.

- Control of speed and torque ratios.

- Versatile applications in various industries.

- Reliable and long-lasting when properly maintained.

- Enable the adaptation of rotational motion to specific requirements.

Disadvantages of Gear Trains:

- Mechanical losses due to friction and wear.

- Limited speed and torque range in simple gear trains.

- Increased complexity and maintenance requirements in compound and epicyclic gear trains.

- Noise generation, especially at high speeds.

- Need for lubrication and periodic inspection to prevent wear and damage.

Frequently Asked Questions:

What do you mean by gear train?

A gear train is a mechanical system consisting of two or more gears connected to one another in such a way that they transmit motion and power from one shaft to another. These intermeshing gears work together to change the speed, direction, or torque of rotational motion in machinery and mechanical systems.

What is gear train and its types?

A gear train is a system of gears arranged to transmit motion and power between rotating shafts. There are several types of gear trains, including:

- Simple Gear Train: Gears connected in series along parallel shafts.

- Compound Gear Train: Multiple gears on common shafts for wider speed and torque ratios.

- Reverted Gear Train: Gears in compound arrangement with coinciding axes.

- Epicyclic Gear Train: Gears that rotate around a central sun gear, creating complex motion patterns.

Why is it called a gear train?

\It’s called a gear train because it resembles a series of interconnected “train” cars where each gear functions like a cogwheel. These gears work together sequentially to transmit motion and power, just as cars in a train follow one another in a line.

What is a gear train example?

An example of a gear train is the gear system in a bicycle. The chainring (attached to the pedals) drives a smaller gear on the rear wheel, allowing the rider to pedal more easily uphill (higher torque) or pedal faster on flat terrain (higher speed).

Why are gear trains used?

Gear trains are used to:

- Change speed: Gear trains can increase or decrease rotational speed, adapting machinery to different tasks.

- Change torque: They can multiply or reduce the force applied to a load.

- Change direction: Gear trains can reverse or redirect rotational motion.

- Control motion: Gear trains provide precise control and synchronization in various mechanical systems.

Where are gear trains used?

- Gear trains are used in a wide range of applications, including:

- Automotive transmissions for changing gears and controlling speed.

- Industrial machinery for manufacturing processes.

- Clocks and watches for precise timekeeping.

- Robotics to control movement in robotic limbs and joints.

- Aerospace systems for adjusting flaps and landing gear.

- Printers and copiers for paper feed and control.