Introduction of a Automobile Engine:

Automobile Engine Parts: In this article we will discuss about main parts of automobile engine and their uses. The detailed explanation about automobile engine parts is as follows.

The engine is a mechanical device which develops heat by burning fuel and converts the heat into mechanical energy. This mechanical energy helps to run the vehicle.

Main Parts of an Automobile Engine:

Th Following are the Main Parts of Automobile Engine:

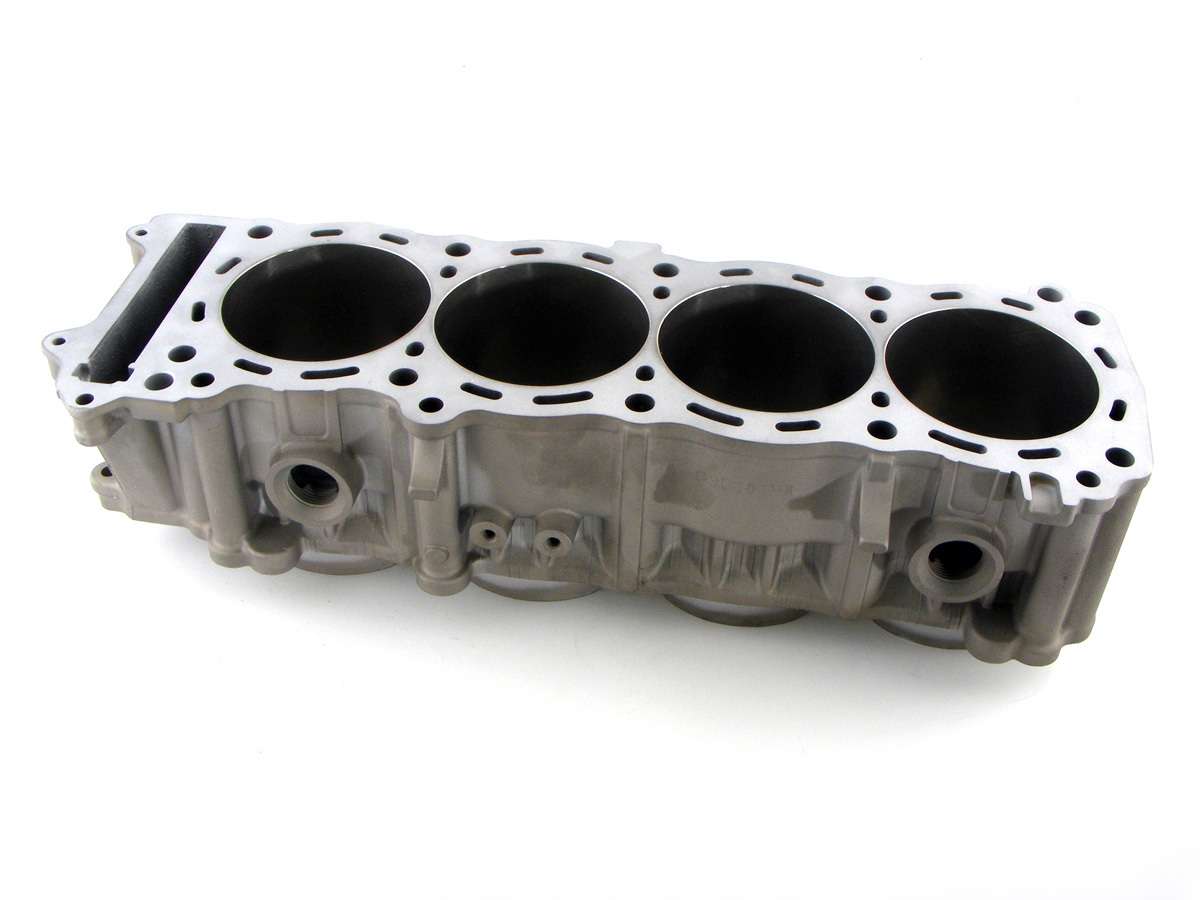

Cylinder Block:

The cylinder block is the main part of the engine due to the complete process runs in it. this block should be with a high internal surface finish and with high dimensional accuracy due to the piston slides inside the cylinder with close tolerance to avoid leakages. the cylinder block should withstand to a high temperature and corrosion to avoid damages. To decrease the high temperature produced in the cylinder lubrication system is used, which is placed at the bottom of the cylinder block called oil pan. Cylinder blocks are generally made by gray cast iron, nickel, and aluminum.

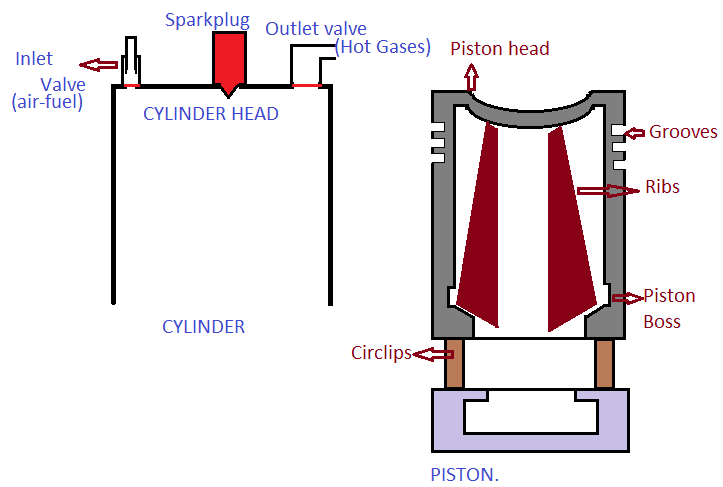

Cylinder Head:

Cylinder Head is the top part which is placed on the top of the cylinder block. a cylinder head is provided with the inlet, outlet valves, gasket for retaining strength for compression and work as leakage resistance between cylinder head and cylinder block and spark plug for ignition purpose at the end of the combustion process. to resist to high-temperature alloys are used to manufacture cylinder blocks like Aluminium.

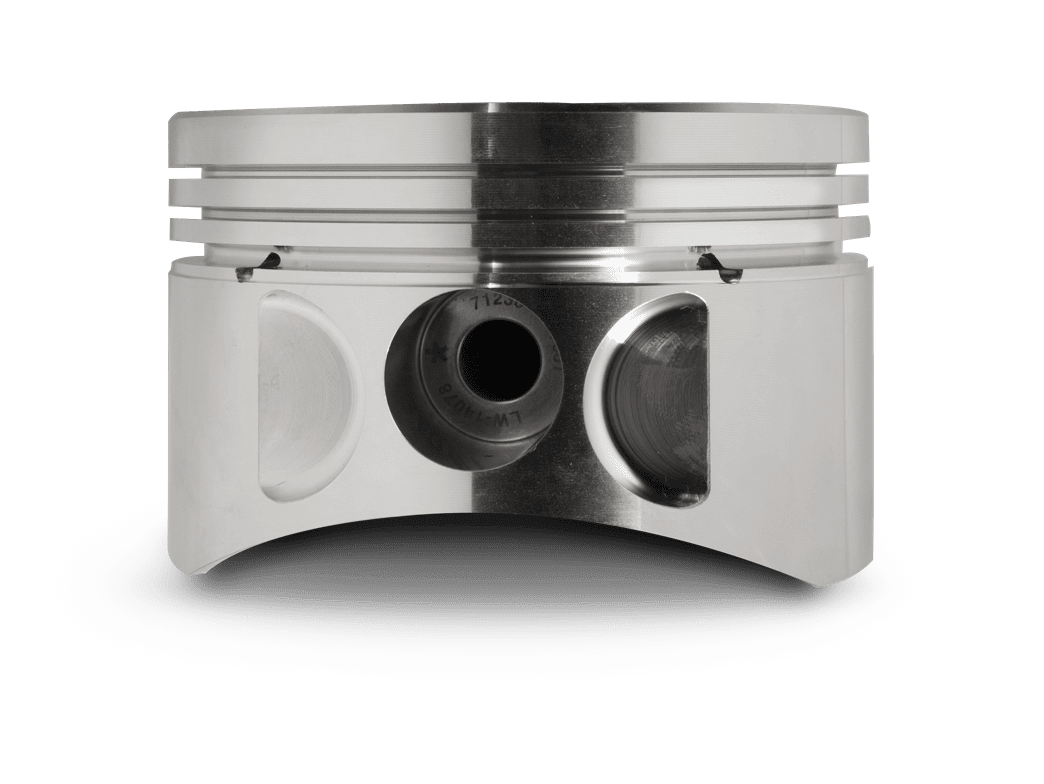

Piston:

A piston is a larger element in a whole engine and plays a major role in internal combustion engines in converting heat into mechanical work and makes the parts to move. the piston should be with a highly smooth surface and should maintain a clear tolerance with a cylinder to avoid leakages. The piston should withstand high temperature and pressure at the time of compression and expansion. and at higher speeds, the piston reciprocates fast to move according to the speed, pressure, temperature the piston should be designed with lighter and stronger materials like alloys steel, aluminium, cast iron etc.There are grooves provided on the piston to place rings called piston rings, this helps in controlling the leakages of compression fuel, exhaust gas and cooling oil. and at the end of the piston, there is a pin to connect with connecting rod.The piston is divided into different parts upper portion of the piston is called as top land and below the top land, it is called a piston barrel.Piston barrel consists of Grooves, Piston boss, Cir-clip etc. this all makes the design of piston complex.

Connecting rod:

The connecting rod is used to convert the linear motion of a piston into circular motion which is an important role in a vehicle this process is carried by connecting one end of connecting rod to piston rod and another end is connected to the crankshaft.

Crankshaft:

Crankshaft makes a rotational movement with the help of connecting rod which is connected at one end and this shaft is connected to gears and flywheel to control the speed of a vehicle.

Flywheel:

A flywheel is a heavy device which is connected to the crankshaft to store the energy in it and supplied whenever require. the flywheel consists of different sizes which related to the number of cylinders used.

Valves:

There are two valves present on the cylinder which allows inlet of the air-fuel mixture and exhaust gases. in a suction stroke, the inlet valve opens and allows the air-fuel mixture into the cylinder and at the time of combustion, both the valves are closed to not allow the gases pass out from the valves and helps to high compression and ignites the fuel with the help of spark plug. these valves are operated with the help of camshaft.

Vibration device:

This is used to protect the engine from vibration damages, this is placed on the front of the crankshaft. due to the high rotational speed of the crankshaft vibrations are developed in between connecting rod and crankshaft. to reduce vibration developed this device is used.

Also Read: CARBURETOR WORKING.