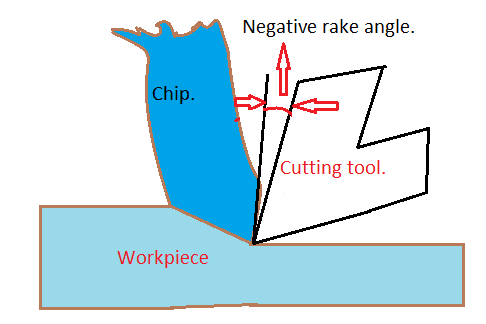

Negative Rake Angle:

Negative Rake Angle: Negative rake angle is the cutting angle and it takes a crucial part at the machining process. We explained clearly about total geometry of single point cutting tool before. the main strength of the cutting tool depends on the rake angle, here we get the point why rake angle plays a major role in the cutting process. Especially Negative rake angle mostly consider while cutting hard, tough and strong metals like Aluminium oxide, silicon carbide etc..

While cutting tough and strong materials heat generated is high, so the cutting tool should maintain the required negative rake angle to resist shocks and temperature at that stage. there is also a high possibility in producing high friction rate, Tool wear, surface roughness, imperfections etc. To minimize all these factors negative rake angle takes a crucial part in the machining hard and tough materials. When we follow the required cutting angles we can overtake some disadvantages like Wear, friction, temperature, tool life etc.

Advantages of negative rake angle:

- There is a chance to increase in tool life.

- Smooth surface can be obtained.

- Cutting speed can be increased.

- Cutting tool strength can be increased.

- Imperfections are eliminated.

- Depth of cut can be increased by maintaining a required rake angle.