Solidification Of Casting and Different Types of Solidification.

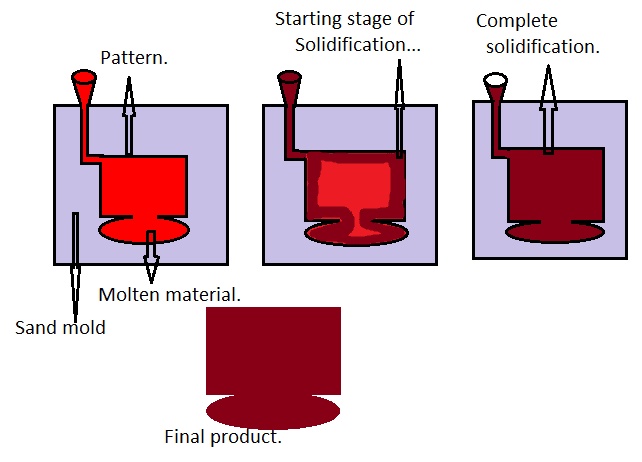

Casting: Casting is a method to manufacture a product in a required shape, to develop an object by using casting operation the metal should be heated to a liquid state, this state of metal is known as molten metal. this molten metal is poured in the mold to obtain a required object. at this stage, solidification is considered an important function in the rate of cooling a molten metal.

Solidification Of Casting:

- Solidification is known as the rate of heat removed from molten metal to mold. Heat removing process to obtain a product from casting is an important method.

- The product obtained by the casting process depends on the solidification time, a method of solidification etc..

- In manufacturing a product by using a casting process solidification is important to consider it’s functions.

- Solidification plays an important role in the casting process to remove the heat from molten material to obtain a required object with better surface finish.

- The process of heat lost from a molten metal is depends on the casting process. and the main solidification depends on the volume and surface area of casting.

- A product obtained from the casting process may contain smooth or rough surface this depends on the solidification time if the time taken for solidification is

- more then the surface of the product may smooth than the fast rate of solidification.

- The main factor/property of the metal density and latent heat also depends on the solidification process. It also depends on the casting shape.

- The time of solidification is directly proportional to the volume of surface area.

There are two different solidification process, they are as follows:

- Directional solidification

- Unidirectional solidification

Directional solidification:

Directional solidification is a fast solidification process than unidirectional one, in this system, the process of cooling starts from the bottom of the mold and reaches to top.

Due to the fast rate of cooling the object obtained is not so smooth surface. this type of process is used in making turbine blades.

Unidirectional solidification:

Unidirectional solidification is a slow solidification process compared to directional one, the cooling of molten metal in mold starts from top to bottom, the object obtained from this process contains a smooth surface. this process is used in manufacturing turbine vanes.