Rivets and different types of riveted joints:

Rivets: Rivets are the type of permanent joints, they are used to join the different types of metals. this joints can be removed without affecting the base metals. rivet that used once cannot be reused.There are different types of rivets they are as follows.

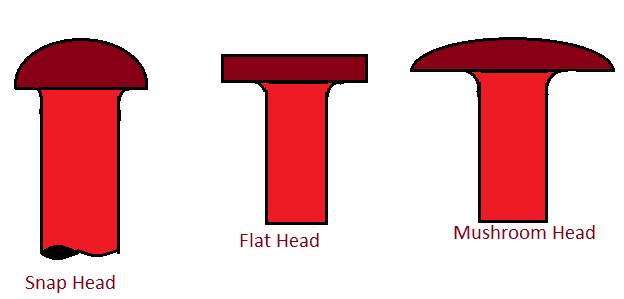

Different types of Rivets:

The Following are the different types of Rivets

- Snap head

- High button head

- Pan head

- Flathead

- Cone head

Types of Riveted Joints:

The Following are the different types of Riveted Joints

- Lap joints

- Butt joints

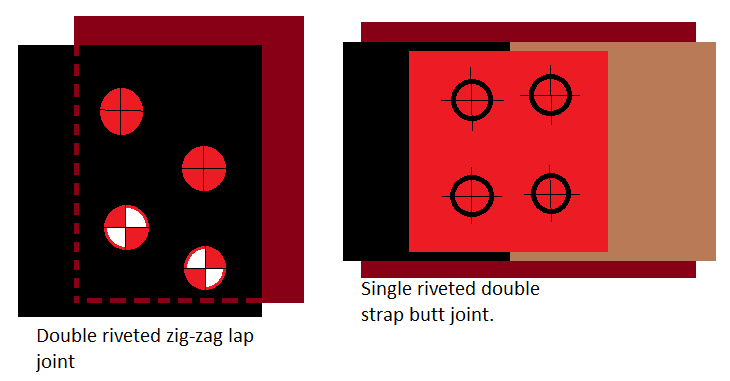

Lap joints

- When the arrangement of the plate is palced one over another and joined by rivets then this is called Lap joint.

- In Lap joint according to the number of rows in joining the plates, there are two types one is Single reverted lap joint, and the second one is Double riveted lap joint.

Butt joints

When the arrangement of the plate is placed side by side with close tolerance (fit) and placing an extra plate over it or below or by placing two plates and joining with rivets is called Butt joint.

In Butt joint according to the number of cover plates placed on metal sheets to join them, there are two types:

- Single strap butt joint and

- Double strap butt joint

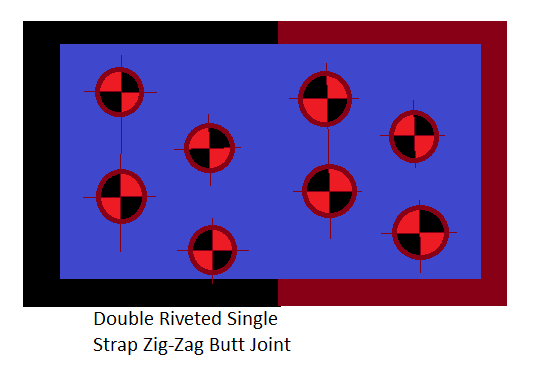

And there is a different riveted joint according to the combination like,

- Single riveted double strap butt joint

- Double riveted double strap butt joint

According to the rivets arranged to join the metals, there are Chain riverted joint and Zig zag joint.

Riveted joints may lead to failure due to Shearing, Crushing, tearing etc.

If we want to join the two metals there are various method to join in rivet type, we can use an extra material or by making both the metals side by side.

But this type of process includes more stress due the base metal need holes to insert the rivet in it and there is an vibration developed at the time of pressing the rivets to attach the metals.we can join metals, non-metals, alloys etc.

Riveted joining is a costly method and the rivet should withstand to vibrations, load and stress.

This is not a permanent joint we can remove the fixed rivet when ever required and the base metal does not undergoes to huge damages when this joint is removed.