Porter Governor:

Porter Governor: Porter governor is a type of simple governor which is an updated from watt governor, Porter Governor is a type of governor contains two equally weighted balls connected to the arm. This ball contains some specified weight and this is a simple construction and easy in maintenance. Porter governor is used to decreasing the fluctuations developed in the engine and supply the required quantity of fuel to the engine according to the load applied to it.Supply of fuel depends on the displacement of the sleeve from its bottom point and this sleeve lifted with the help of balls rotation, when the balls rotate with high speed the sleeve lifted to the maximum point and the supply of fuel is maximum to the engine.

Construction of Porter Governor:

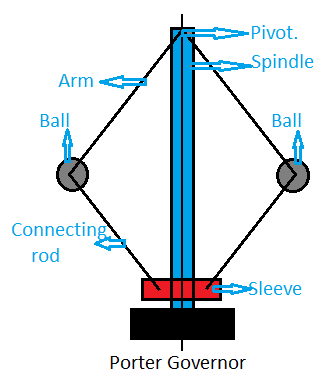

The balls are connected to the arms as shown in the figure and these arms get connected at a single point called pivot as in the figure, and the sleeve present on the bottom of the spindle connected to the balls to move in up and down direction, due to this momentum the supply of fuel is done.

Main parts of Porter Governor:

The following are the main parts of Porter Governor:

- Pivot

- Arms

- Balls

- Connecting Rod

- Sleeve

- Fuel Pump

Pivot:

- This is the point at the top end which connects the arms.

Arms:

- This is connected to the balls and makes rotations along with the balls.

Balls:

- Balls connected to the arm and this balls has some specified weight according to the application and this helps to move the sleeve up and down direction, due to the connection between the sleeve and the ball.

Connecting rod:

- This is used to connect between the balls and the sleeve.

Sleeve:

- Sleeve gets connected with the balls with the help of connecting rod to slides on the spindle and which helps to flow the fuel from fuel tank to engine.

Fuel pump:

- This is used to supply the fuel from the fuel tank to the engine when the sleeve moves in an upward direction and stops when the sleeve reaches the bottom endpoint.

Working of Porter Governor:

- When the balls attached to the arms rotate, the sleeve gets moved in an upward direction due to the connection between the balls and sleeve, and this momentum helps to flow the fuel from storage tank to engine.

- when the sleeve moves in the upward direction the fuel pump connected to it supplies the fuel according to the momentum of the sleeve, with the help of this process the fluctuations can be reduced and helps to function in a smooth condition.

Also Read: Hartnell Governor, Proell Governor, Watt Governor.