What is a Clutch?

In this article, we will discuss the clutch and types of clutches. A Clutch is a device that used to transmit the power from a rotating shaft to an idle shaft. The clutch is used to change the speed ratio according to the running conditions. Depending upon the transmission, power, torque, smoothness, heat, lubrication, manual, automatic, cost, Maintenance, etc. By considering all these factors the required clutch is selected. Due to high-speed rotation and friction, some of the clutches are more complicated to use they need cooling oil, regular maintenance, etc. Without using a clutch we cannot transmit the power from one shaft to another shaft. Clutches are made with strong material and they should withstand high-temperature resistance and corrosion resistance.

Types of Clutches:

There are different types of clutches they are as follows

Dry Clutch:

A dry clutch system does not use any cooling oils it is a type of Non-lubricating device. it uses only air as a cooling medium. this type of clutch is used mostly in racing bikes which transfers more torque, due to easy in cleaning and faster in replacing. and this type of device is used for a smoother function at higher RPM. this is easy to maintain. This type of clutch gets engaged with the pressure applied by the spring. Dry clutch is not provided at an inner portion of the motorcycle this is placed as an external part of the system.

Wet Clutch:

The wet clutch is a device which uses a cooling oil due to high heat developed init, this type of device required a lubrication system. due to this system provided init, the coefficient of friction gets decreases and by this, the transmission of torque decreases which is less than dry type. This is provided in a closed area due to it needs regular contact with cooling oil.

This is not as smooth as dry type and maintenance is not an easy process. This type of clutch gets engaged with the help of hydraulic pressure, by this, it is stronger in contact than a dry clutch.

Dog Clutch:

The dog clutch is a different type that used among all the remaining clutches. Dog clutch contains teeth on the circular disc which used to intersect with the rotating shaft at the time of transmission. in this type of clutch, there is no slipping occurs and transmits more torque.

Single plate clutch:

This type of clutch has only a single friction surface plate to make a contact with a rotating shaft to transmit the power from one shaft to another shaft. in this type of clutch, the spring pressure is used to engage and disengage the clutch. single plate clutch uses more space than a multi-plate clutch.

Multi-plate clutch:

This type of clutch contains more than one clutch plates, this type of clutch occupies less space compared to a single plate clutch, we can use this clutch where the required area is less for transmission purpose. this type of clutch transfers more torque comparatively than a single plate.due to more heat developed at the power transmission it required a lubrication system, by this lubrication system coefficient of friction, gets decreases.

Cone clutch:

Cone Clutch is the olden method process nowadays we use disc type clutch which replaces the cone clutch. cone clutch contains only one pare of friction surface on it. Due to the frictional attachment made at the contact surface, the torque is transmitted from one shaft to another, but in some cases, spring is used around the driven shaft in contact with the hub of the driven shaft material.

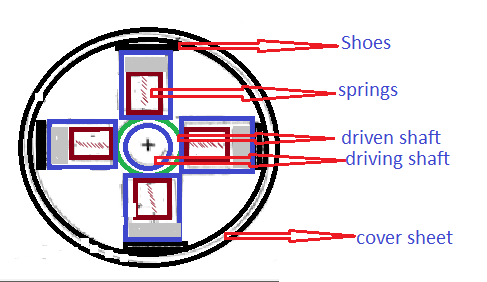

Centrifugal clutch:

This type of centrifugal clutch is usually placed into the motor pulleys. There is a shoe provided inside the rim of the pulley. The shoe with outer area/surrounding is covered with the help of friction material, to move the shoe radially they provided with guides in it. this type of clutch is more useful.

This centrifugal clutch helps to increase the speed and which makes the shoe to press harder and helps to increases the torque to transmit.

Hydraulic Clutch:

This type of system works on the basic principle of fluid flow. in this type of clutch, low pressure is enough to disengage the clutch from rotating shaft. This is a more effective system. this is a costly method to replace. and in this type of clutch high power and torque are transmitted. this type of clutch needs the same fluid used in brake fluids. due to more efficiency, it is used in heavy vehicles to transmit more power.

Electromagnetic clutch:

This is also known as the Electro-Mechanical clutch. the output of the system is mechanical transmission which is done by electrically. this type of clutch is a costly one to use. The engage and disengage of a clutch is done through an electricity supply and generating a magnetic field to comes in contact with the rotating disc. this type of system is easy to operate. but the temperature generated at the time of operation is high.