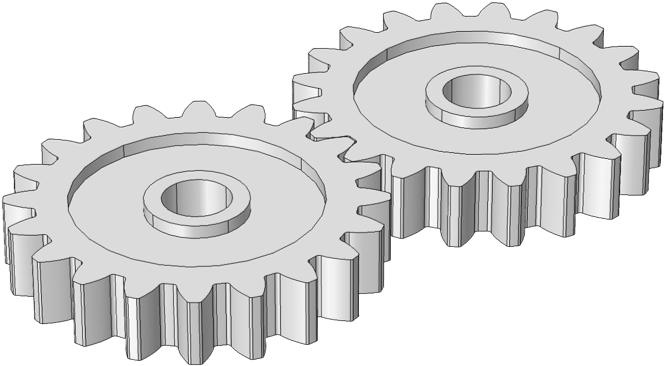

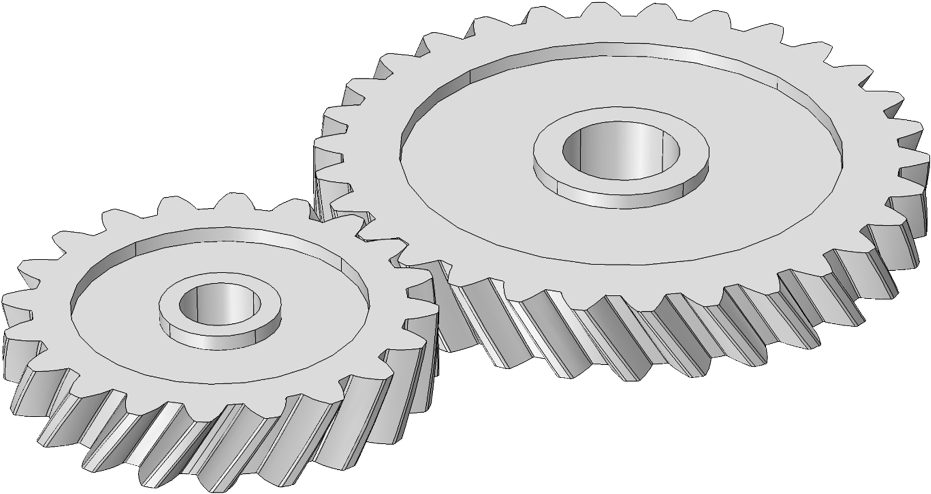

Difference between the Spur Gear and Helical Gear?

- Spur gears are mostly used in industrial applications whereas helical gears are mostly used in mechanical applications.

- Spur gears are generally made up of two or more teeth fixed on a common shaft while helical gears consist of two or more rotating components fixed on each other so as to rotate together around a common axis.

- Helical gears are a type of gear that has a helix-shaped ring. The helix is the spiral shape that forms when an object rotates around its axis. They are often used in transmission systems because they allow for much tighter turns than spur gears, which also happen to be more expensive. Helical gears are typically used in applications where precision and speed are critical.

- The spur gear can be used for turning shafts of smaller diameter, whereas the helical gear is most commonly used in larger shafts.

- Spur gears are used in applications where high rotational speeds are required.

- Spur gears are very compact and easy to manufacture.

- The advantage of spur gears over helical gears is they can be used to transmit power at higher torque levels without having to increase their diameter which increases weight and cost.

- Spur gears have the ability to maintain constant tooth contact with less noise than helical designs due to no loss of stiffness when under load (as opposed to both types).

- Spur gears are more compact than helical gears because of this design feature.

- Spur gears are more flexible than helical gears.

- Spur gear teeth can be made either parallel or normal to the axis of rotation so both types of spur gear may be constructed using either design approach although parallel tooth designs tend to be stronger than normal tooth designs due to the perpendicular nature of the teeth at rest.

- Spur gear does not generate any noise while rotating unlike helical gear.

- Helical gears are of high strength and durability.

- Helical gears have higher performance because they can transmit more power with less friction.

- Helical gears are more efficient compared to spur gears.

- Helical gearboxes are made up of high-quality materials such as aluminum alloy, titanium, and chrome-plated steel, this helps ensure that your product does not rust or corrode easily.

- Helical gears have only one row of teeth and they have fewer steps between the two rows than those found on spur gears.

- It transmits power from shafts to shafts without having to use any form of differential mechanism such as a planetary gearset or worm drive.

- If you want your application to have the capability to withstand heavy loads then you should go with helical gear instead of spur gear since its strength comes from its teeth rather than being strong due to its size.

- Helical gears are less expensive compared to spur gear costs which might be quite higher than helical gear costs too.

- Helical gears rotates smoothly or accurately.

Spur Gear

Helical Gear