Difference between Welding and Fabrication

What is Welding?

- Welding is a process of joining materials or components by melting them together. The materials are melted at high temperatures to form a joint.

- It is used to join several items together in a way that they cannot separate easily.

- Welding can be done in several ways. Here are some methods:

- Gas welding, arc welding, gas tungsten arc welding (GTAW), submerged arc welding (SAW), oxy-fuel cutting, oxy-fuel cutting, electro slag, and friction stir welding.

- The types of welds used in different industries include butt welds, fillet welds, lap joints, tee joints, and overlaps. The amount of heat required to melt the joint depends on the type of metal being joined.

- Welding also allows for additional materials such as filler metal to be added to strengthen the joint between the pieces being joined.

Welding

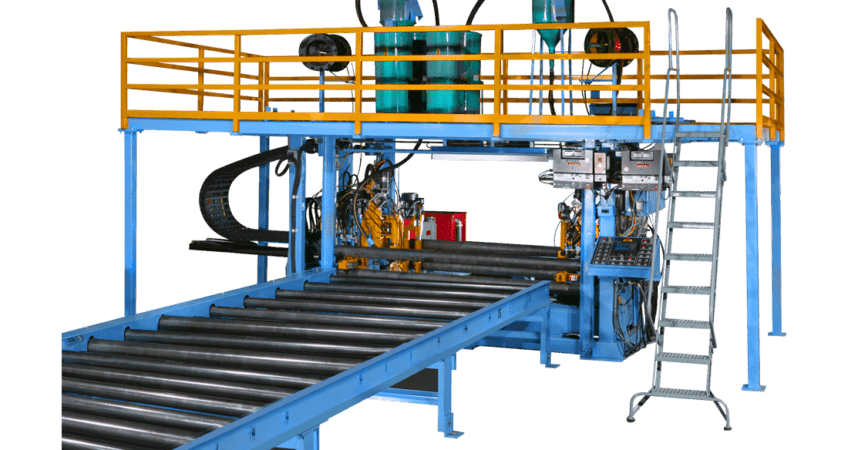

What is Fabrication?

- Fabrication is the process of creating something from raw material, or it is a process of cutting, bending, and joining metal sheets to make parts or components. It is the basic form of fabrication that gives shape to metalwork. The fabrication process requires working with sheet metal, aluminum alloys, castings, etc.

- These methods have been used for centuries and continue to evolve as technology advances in order to create more efficient ways to manufacture products from metals such as steel and aluminum with fewer steps per product produced than traditional methods such as forging where you need multiple people working at once including an anvil smith who hammers down your item with one blow.

- Fabrication can be done using an injection molding machine or other similar machines that help in forming the desired shape out of metal sheets. Fabrication is useful when you need to create new parts or make changes to existing ones because it does not require welding which involves the use of heat and electricity for melting metals.

- types of metal fabrication: casting, extrusion, and rolling.

- Casting is probably the oldest method of metal fabrication in which a mold is created from a pattern or model using molten metal or alloyed materials poured into it.

- Extrusion involves using a machine to pull out strands of material from a block of material called a die, similar to how sausage casings are made.

- Rolling can be accomplished either manually or automatically depending on the type of material being rolled out.

- You can also use fabrication to create custom shapes and designs that might be used in the design of various products like fashion accessories, furniture, architectural models, and even artworks.

Fabrication