Advantages and Disadvantages of A.C Arc Welding

What is A.C Arc Welding?

Arc welding is a type of welding that uses an electric arc to melt metal. This type of welding process is used to join metal parts by heating the workpiece with an electric current, which melts the metal and forms a weld pool.

This process can be used on thin materials such as sheet metal or plates. This technique also produces less heat than other types of welding processes.

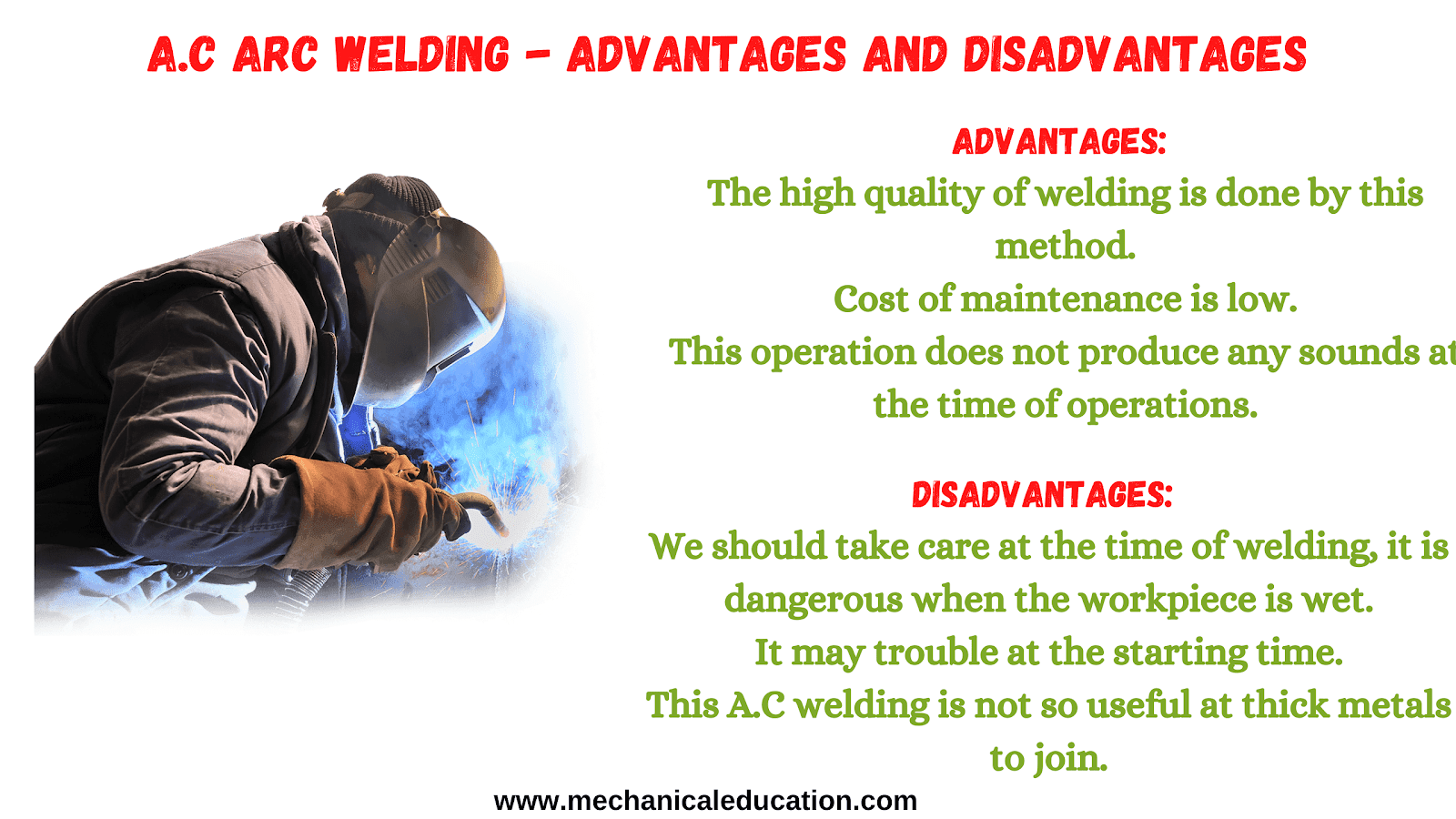

Advantages of A.C arc welding:

- The high quality of welding is done by this method.

- Cost of maintenance is low.

- We can control this welding with a smooth process.

- This operation does not produce any sounds at the time of operations.

- We can weld most of the metals with this welding process.

Disadvantages of A.C arc welding:

- We should take care at the time of welding, it is dangerous when the workpiece is wet.

- It may trouble at the starting time.

- Deformation of a workpiece is more.

- This A.C welding is not so useful at thick metals to join.

- Comparing to D.C type, A.C is not so effective at welding.