Broaching – Advantages and Disadvantages

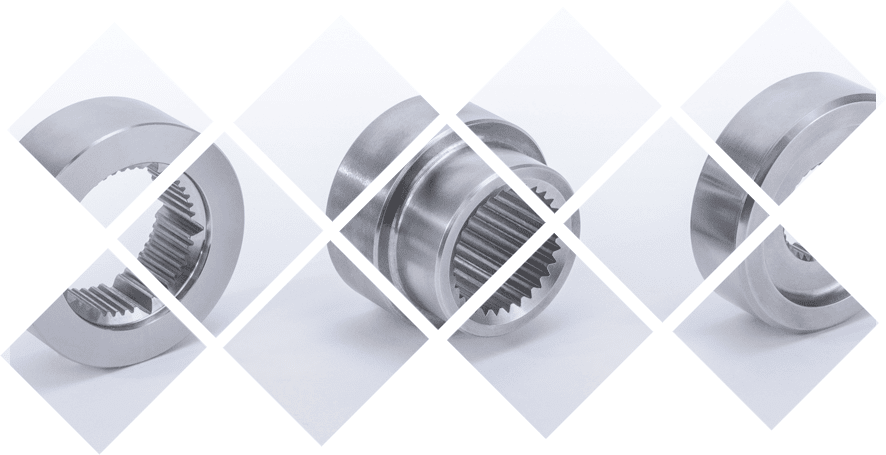

What is Broaching?

Broaching is a machining process that uses to remove the inner & outer surface of material by using a toothed tool called a broaching.

Advantages of Broaching:

- Broaching is a very efficient way to create complex shapes and slots.

- It is a versatile process that can be used to create products in a wide range of materials.

- It is a fast process because most of the surface finish gets in a single broach.

- Broaching produces clean and accurate cuts, which can improve the performance and lifespan of the finished product.

- It is simple to operate.

- A less skilled person can operate the machine.

- Both internal and external surface finish can be done through this process.

Disadvantages of Broaching:

- Broaching is a complex process, so it can be expensive to set up and run.

- The cost of broaching tools is expensive.

- Broaching requires close attention to detail, which can make it unsuitable for large-scale production.

- Obstructions on the work pice decrease the quality of broaching.

- A larger size workpiece cannot be broached.

- Workpiece that get to be broached should withstand to high pressures.

- Broached parts are also much more difficult to alter after the machine has been programmed.