Cutting Fluid: Definition, Purpose, Properties, Types, Applications:

What is a Cutting Fluid?

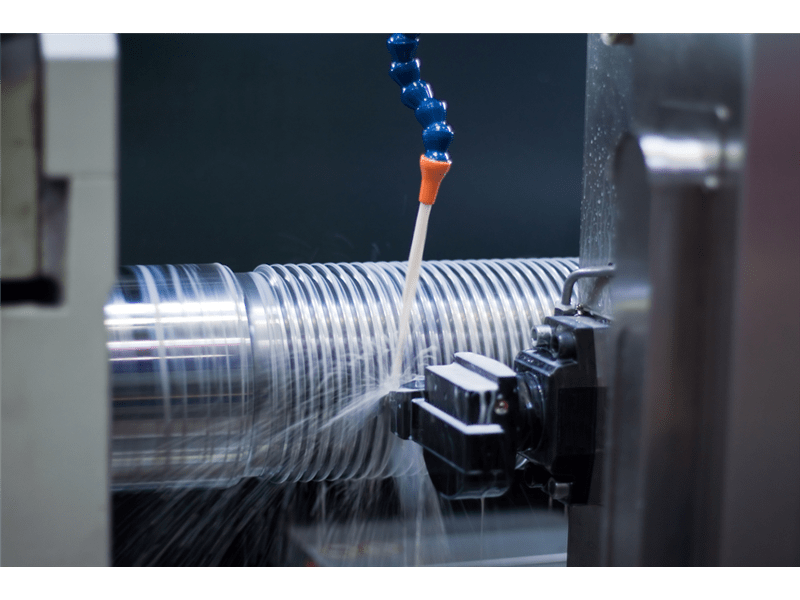

Cutting fluid is a type of lubricant that is applied to the cutting edge of a tool to cool and lubricate the material being cut. Cutting fluids are also used to flush away debris and protect the tool from wear. There are many different types of cutting fluids, each with its own set of benefits and drawbacks.

Types of cutting fluids:

Cutting fluid that is used to cool the Cutting zone. There are different types of Cutting Fluids, they are as follows:

- Oils

- Coolants

- Cutting Fluids

- Machining Fluids

1. Oils:

Oils are a type of Cutting fluid that is made up of a petroleum base. Oils are effective at cutting and lubricating metals, but they can be messy and difficult to clean up. They are also combustible, meaning that they can create an explosion hazard. Cutting Fluids are similar to oils but contain additives for increased cooling and lubrication properties. Cutting Fluids do not combust or leave behind a residue like Oils.

2. Coolant:

Coolants Cutting Fluid that is used to cool the Cutting zone Coolant is a type of. Coolants are made up of water and a chemical additive that helps to dissipate heat. Coolants are often used in applications where high temperatures would damage the Cutting tool or workpiece. Coolants are also effective at removing chips from the cutting zone, which can improve the quality of the cut.

3. Cutting Fluids:

Cutting Fluids A Cutting Fluid is a type of Cutting fluid that contains chemical additives that increase its lubricating and cooling properties. Cutting Fluids are less combustible than Cutting Oils, but they do contain chemical additives. Cutting fluids can also be effective at reducing chips and reducing wear on the tool. Cutting Fluids can also contaminate the workpiece and result in poor finishes, so proper flushing is required to remove them from the Cutting zone. Cutting fluids are often used to cut through hard materials such as ceramics and concrete.

4. Machining Fluids:

Machining Fluids A Machining Fluid is a type of Cutting fluid that is used in high-speed machining applications such as milling and turning. These fluids contain additives for increased cooling and lubrication, but they also contain properties that prevent chips from depositing on the Cutting zone. This prevents Cutting fluid loss and allows machines to continue Cutting through long workpieces before needing to refill Cutting fluid reservoirs. The Chemicals used in Machining Fluids are often highly toxic, so proper ventilation is required when using them.

Cutting Fluid Properties:

- There are several cutting fluid properties that are important to consider when selecting the right cutting fluid for a specific application. The most important of these include:

- Cutting fluid viscosity: The higher the viscosity of cutting fluid, the more it will resist flow. This is important because it helps to prevent the cutting fluid from being sheared too quickly by the cutting action, which would result in the cutting fluid not staying in place between the cutting tool and workpiece.

- Cutting fluid density: Dense cutting fluids will provide better lubrication than cutting fluids of lower densities. They also form thicker films, helping to prevent cutting tool wear. However, dense cutting fluids are more difficult to pump and can be more expensive.

- Cutting fluid wetting ability: The better a cutting fluid wets the workpiece, the less friction there will be between the two surfaces. This leads to longer tool life and improved cutting performance.

- Cutting fluid miscibility: Some cutting fluids are miscible (able to mix together) while cutting fluids that are immiscible (cannot mix together) will separate into layers. In some cases, cutting fluids with the same miscibility level may have different shear stability levels.

- Cutting fluid chemical make-up: The cutting fluid’s chemical make-up can affect its ability to resist thermal degradation and oxidation. It can also affect the cutting fluid’s ability to wet the workpiece and form a protective film.

- When selecting a cutting fluid, it is important to consider all of these cutting fluid properties to ensure that the cutting fluid will be effective in your application.

Cutting Fluid Applications:

- Cutting fluids are essential tools for manufacturing companies that use metalworking processes. Cutting fluids help to protect the cutting tool and workpiece from excessive heat and friction during machining, which can decrease productivity and cause product defects. Cutting fluids also cool the workpiece and lubricate the surface of the machine tool (Wikipedia).

- Cutting fluid is applied in various ways, depending on the type of machining process and the equipment being used. In some cases, a small amount of cutting fluid is sprayed directly onto the cutting tool and workpiece. In other cases, a large volume of cutting fluid is pumped through a system of hoses and nozzles that surrounds the work area. Cutting fluids can also be applied by a combination of these methods. Cutting fluids come in a variety of liquids and mixtures, often specialized for specific workpieces or operations. Cutting fluid may also contain additives that enhance its ability to cool and lubricate while also repelling contaminants from the surface being machined.

- Water-soluble cutting oils. Cutting oil is the most common type of cutting fluid, and is often used in metalworking manufacturing processes like turning, milling, drilling, tapping, reaming, and boring (Ames 2001). Cutting oil may be applied directly to the workpiece with oil nozzles or soaked into a lint-free cloth that is pressed to the workpiece. Cutting oil is also used in machining centers with internal, wall-mounted oil reservoirs that continuously release a steady flow of cutting fluid over the cutting area.

- Soluble oils are liquids consisting mainly of hydrocarbons that mix well with water or brine solutions without separating them into layers.