Dial Indicator? Construction, Advantages and disadvantages, Application and Uses?

What is a Dial Indicator?

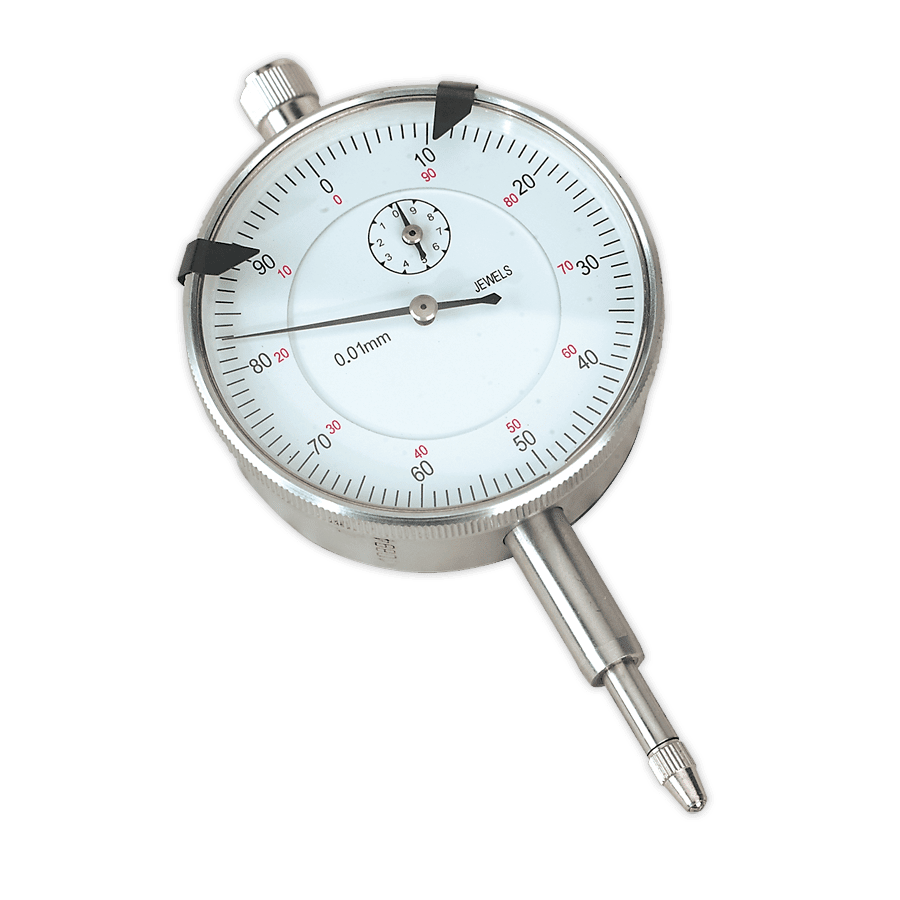

A dial indicator is a small instrument that can be used to measure the depths very accurately and deviation from one point to another. It is often used in machine shops. It works by showing how far things are apart on a scale.

The dial indicator concept was developed by George Goodall of Reading Pennsylvania in 1901, who joined with his brothers to form the company that would become renowned as Daimler-Chapman Incorporated-the first indicator manufacturer in the United States.

Dial indicators are used for measuring the depth of cuts on surfaces before cutting or drilling. It is also useful in checking wrenches, or seeing if some nut needs tightening more.

Construction of a Dial Indicator:

Dial indicator is usually equipped with a sharply pointed stylus. Dial indicator consists of a calibrated dial that indicates the reading on the scale, an adjusting screw for bringing the stylus in line with the required graduation, and generally three steel pointers marked.

Dial Indicator is a measuring device that can be used as a non-destructive testing tool. Dial indicator with its stylus at one end and dial at the other end. Dial indicator with its stylus at one end and dial at the other end allows measurement of displacement, swarf thickness, or wear limits.

A dial indicator typically moves by turning or twisting the outer dials or through sliding one of the two axes until contact is made with the stationary boss. Contact is known as an “indication”. For linear scales, this typically requires additional locking onto a spring hook at specific intervals using rubber-covered thumb screws.

In machining, the dimensional accuracy of a part is very important. Dial indicators are used by technicians to inspect all parts that have been machined or manufactured before accepting them from the manufacturing plant. Dial indicators can also be used with fixtures and gauges if it is necessary to measure the location of a small point on One of the most common uses for dial indicators is checking the objects.

Advantages of Dial Indicator:

- Dial indicator is very accurate and can measure small Dial Indicators.

- Dial indicator is easy to use and does not require any training.

- A dial indicator is simple and intuitive to use as it only requires a few seconds to take a measurement.

- It does not require any complicated calculations or calibration so it can be used by anybody.

- Moreover, precision is created through the use of a blade screw which generates a linear torque proportional to the angular deflection. This minimizes sensitivity error due to non-linearity, hysteresis, neutral position errors, and variability.

- It is easy to read these instruments compared with electronic ones – especially during low ambient light conditions. Another potential benefit is that they’re inexpensive relative to other types of indicator devices such as laser or ultrasonic measures

Disadvantages of Dial Indicator:

- Dial indicator is not very durable and often breaks down after a few uses.

- Dial indicator is expensive compared to other measuring instruments.

- Disadvantages include having the possibility that the surface being measured may be adversely affected by contact with the probe (because it is not appropriate for rough work), sensitivity to contamination (easily slide under object if not stabilized), and susceptibility to electromagnetic interference (EMI).

- EMI causes needle jumps when high-frequency electric pulses come into contact with metal shafts due to magnetic fields around them.

- When installing a point set, you want to make sure that all points are mounted in the same place and at the same height because Misalignments accumulate and create inaccuracies over time, so this is not ideal.

- Their limited accuracy which varies based on the type and uses range.

- Dial indicators are not sensitive enough to measure many time-based phenomena. For example, dial indicators cannot be used for magnetic measurements over a few milliseconds duration. They are also not appropriate to measure any vibration or shock that is fast compared with one-second intervals.

- The dial indicator limits the person using it in space. This can be a disadvantage in some situations, for example in mechanical engineering when designing products where measurements are often taken at different points on an object.

- it is sensitive to gravity so that when measuring something vertically if you are not very careful with your orientation of the instrument to the point being measured, you will get inaccurate readings.

- It tends to jump out of calibration, it is fragile, it is prone to errors in reading.

- If you have an inaccurate dial gauge, it may cause problems with machining production workpieces precisely, which will affect the final quality of your products. For this reason, machine adjustment technicians need to make sure all components are well taken care of and calibrated regularly before they affect the overall performance.

Applications of dial indicators:

- Dial indicators are widely used in engineering, manufacturing, and machining applications. They can be used for linear measurements, checking the concentricity of objects, and measuring the depth of holes. Dial indicators are also commonly used in automotive and other repair shops to measure run-out on rotary parts.

- Machining

- Blade maintenance

- Woodworking

- Machine calibration

- Geometry measurements.

- It is also used for blueprint reading and setting up machines with computing instruments.

- Students use this machine to measure small distances easily and precisely.

- The height of a surface below a point can be measured by setting the pointer against it and moving up until one end of the spider part reaches its hardest position against gravity at its highest point–which will equalize spring tension on all parts.

Uses of Dial Indicator?

- A dial indicator uses a conical (needle) to measure the depth of something. With the use of a dial indicator, you can do more than just check the depth of your drill press or lathe. You can also use this for measuring the depth on your milling machine and other tooling’s such as collets, fixtures, and centers. A dial indicator uses a spring-loaded plunger around the outside of the conical needle to push against, which is connected to an electronic dial indicator that measures both the force and amount of penetration.

- It is also used to gauge various distances to set up, measure, mark, and guide machine tool cutting.

- Dial indicators are very popular due to their economy, ease of use, accuracy, dependability, and wide range of uses.