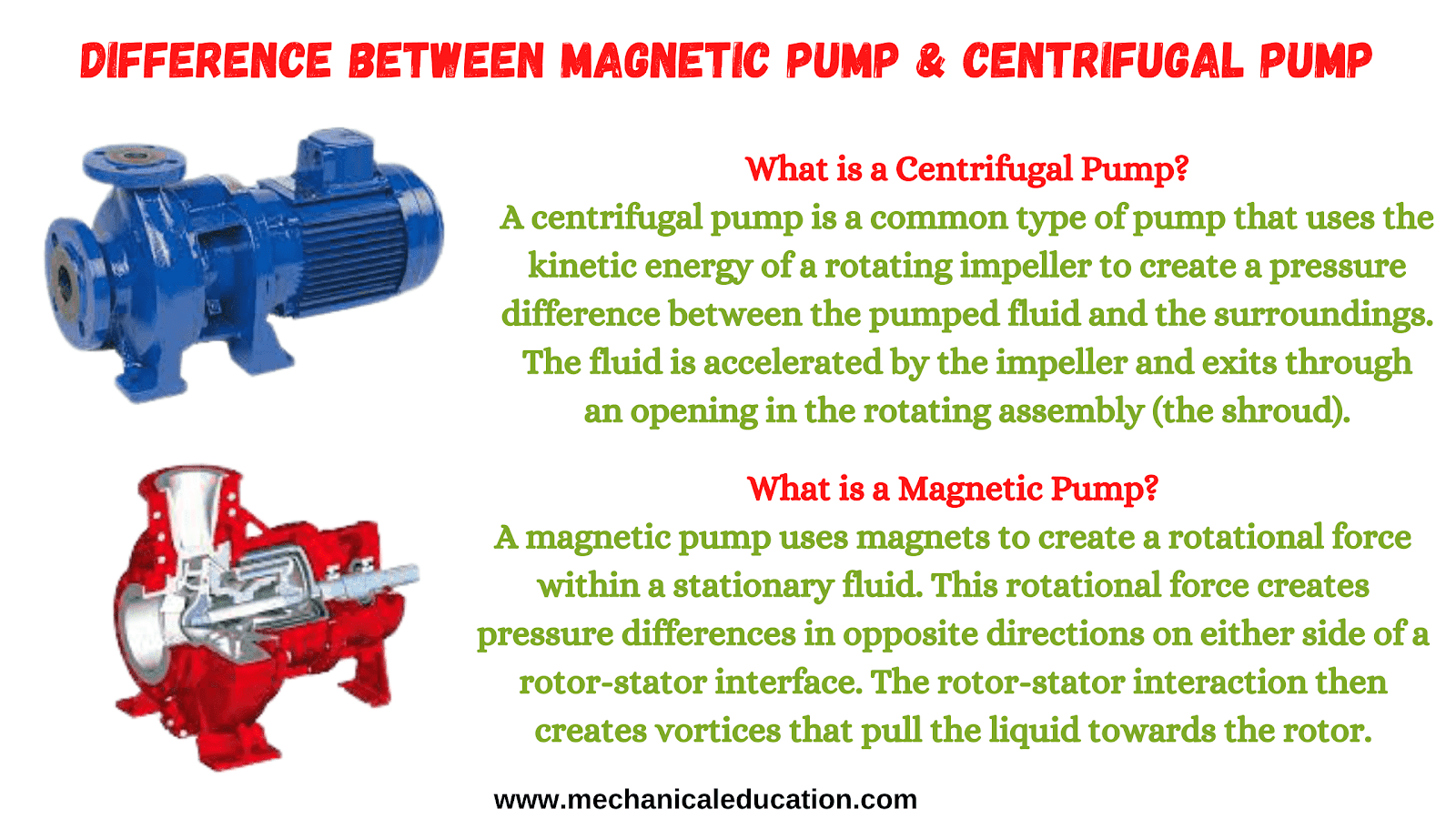

Difference Between Magnetic Pump & Centrifugal Pump

What is a Centrifugal Pump?

A centrifugal pump is a common type of pump that uses the kinetic energy of a rotating impeller to create a pressure difference between the pumped fluid and the surroundings. The fluid is accelerated by the impeller and exits through an opening in the rotating assembly (the shroud).

Centrifugal pumps use a spinning impeller to move the fluid. The impeller is attached to a shaft that is spun by an electric motor. The centrifugal force created by the spinning impeller pushes the fluid out of the pump and into the desired location.

What is a Magnetic Pump?

A magnetic pump uses magnets to create a rotational force within a stationary fluid. This rotational force creates pressure differences in opposite directions on either side of a rotor-stator interface. The rotor-stator interaction then creates vortices that pull the liquid towards the rotor.

Magnetic pumps consist of a rotor that has permanent magnets mounted on them. These permanent magnets create a magnetic field that is used to move the fluid. The strength of the magnetic field created by the magnets determines how much force is exerted on the fluid, and this in turn determines how much pressure can be exerted by the pump.

Difference Between Magnetic Pump & Centrifugal Pump?

Centrifugal pumps work by using a rotating impeller to throw the fluid outwards centrifugally (hence the name), while magnetic pumps use powerful magnets to create a strong force that repels the liquid molecules away from the pump head.

The Centrifugal pump uses an impeller that rotates to create a high-pressure stream of fluid.

A magnetic pump, on the other hand, does not use an impeller but instead uses magnets to rotate inside a stationary casing and creates a low-pressure stream of fluid.

Magnetic pumps are long-lasting than Centrifugal pumps.

Centrifugal pumps create high pressure and power than magnetic pumps.

Centrifugal pumps are better for pumping viscous fluids and slurries, whereas magnetic pumps are better for pumping clean liquids with low or no dissolved solids.

Centrifugal pumps can move more fluid than magnetic pumps, and they are also able to create a higher level of pressure.

The magnetic pump does not need any bearings, but it requires more expensive materials such as rare earth magnets.

The centrifugal pump needs a bearing for it to rotate and generate power efficiently.

Magnetic pumps have no moving parts and can therefore work in a wider range of applications than centrifugal ones. Magnetic pump systems also tend to be quieter and less expensive than their counterparts.