Difference between Malleability and Ductility?

Malleability is the ability of a material to be changed or deformed by simple pressure, while ductility is the ability of a material to undergo plastic deformation.

Malleability is the ability of a material to be deformed under the action of stresses or strain.

Malleability is the ability of a metal to be hammered into thin sheets or rolled into large, flexible tubes. The metal can then be formed by rolling, folding, and pressing the sheet.

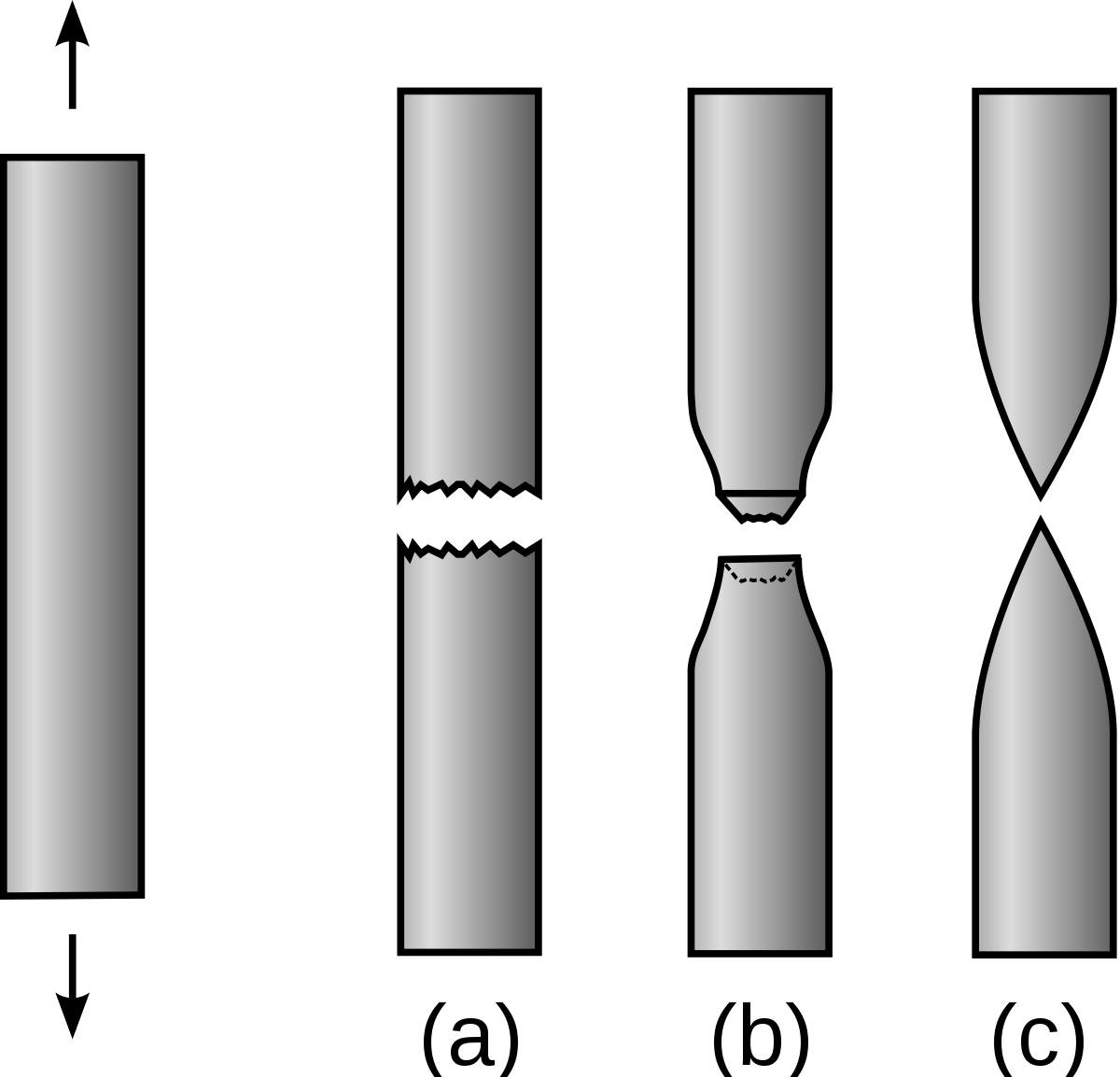

Ductility is the ability of a material to deform under stress without breaking or cracking. It is a measure of how well an object can be deformed or bent without being broken or cracked.

Ductility depends on the size of the applied load, which can range from being elastic (like rubber) to brittle (like glass). The properties are usually defined by their strain-energy relationship

Ductility

Ductility is measured as the ratio between stress and strain under which plastic deformations occur. It can be defined as how much force it takes to cause permanent deformation in a material. While malleability refers to the ability of a material to be crushed by external forces such as rolling over or crushing.