Advantages and Disadvantages of Sand Casting?

Advantages of Sand Casting:

- Sand casting is a very old and simple manufacturing process.

- The production time is very short.

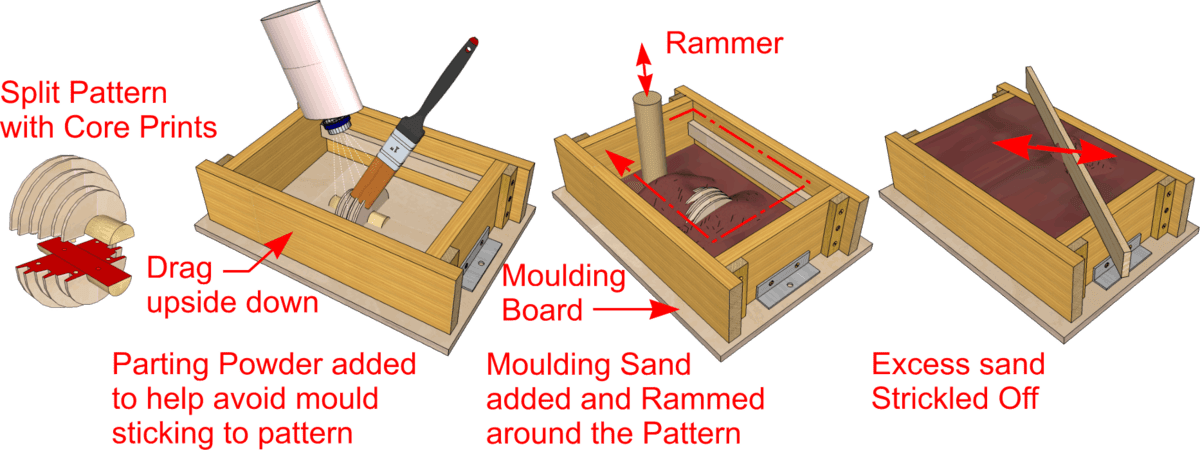

- Sand casting, or sand molds, differs from other metal casting processes by requiring an easily workable material to make the mold.

- The process is inexpensive and does not require expensive furnaces or equipment like centrifugal chillers.

- There are no moving parts to wear down over time.

- It also does not create tear-outs on the inside surface area because undercut hinges are eliminated due to the lack of dies (no undercuts).

- The flow of the molten metal into the cavities has an extremely strong force that perfectly captures the complexity and detail of any given part.

- It can also produce parts in a quantity never seen before, with an astonishingly low cost-per-part.

- It is not only a viable option for high volume production, but one of choice for competitions where time or budget constraints are paramount.

- In contrast, to die casting which limits design complexity by fabricating from a flat sheet steel block, sand casting offers flexibility without sacrificing detail.

Disadvantages of Sand Casting:

- It produces a rough surface finish.

- Lower dimensional accuracy is obtained from sand casting.

- It’s impractical to use without some sort of mold, and molds have some limitations.

- There are some limitations though that prevent us from using this process for all types of items due to the porous nature of sand a protective coating is a must.

- Molds are needed every time since they do not keep their form when the hot molten metal cools within them, unlike with other casting methods such as diecasting or permanent molds such as plaster molds used for rubber injection molding. -This means using more natural resources than most alternative processes, usually water required by damping mixes for clay.