Electroslag Welding Advantages and Disadvantages:

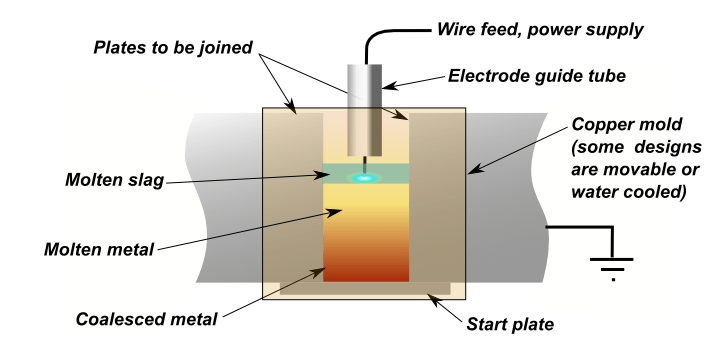

What Is Electroslag Welding?

Image Source: Click Here

Advantages of Electroslag welding

- Due to the slow cooling rate, cold cracking does not occur.

- High productivity can be achieved.

- It is a Low-cost process.

- In this process, slag inclusion or porosity does not affect.

- This welding process is faster.

- This is a semi-automatic process.

- The slag remaining is eliminated.

- A heavier section can be welded in a single pass.

- This process can weld Heavy parts easily.

- Low distortion.

Disadvantages of Electroslag welding:

- It required additional cooling for high-temperature welds.

- The quality of the welding decreases in the fusion zone and the heat-affected zone if the supply of heat is high.

- Cracking may occur in the heat-affected zone.

- It is only useful for vertical position welding.

- It has low toughness to the weld.

- Due to the high heat base meat gets hotter.