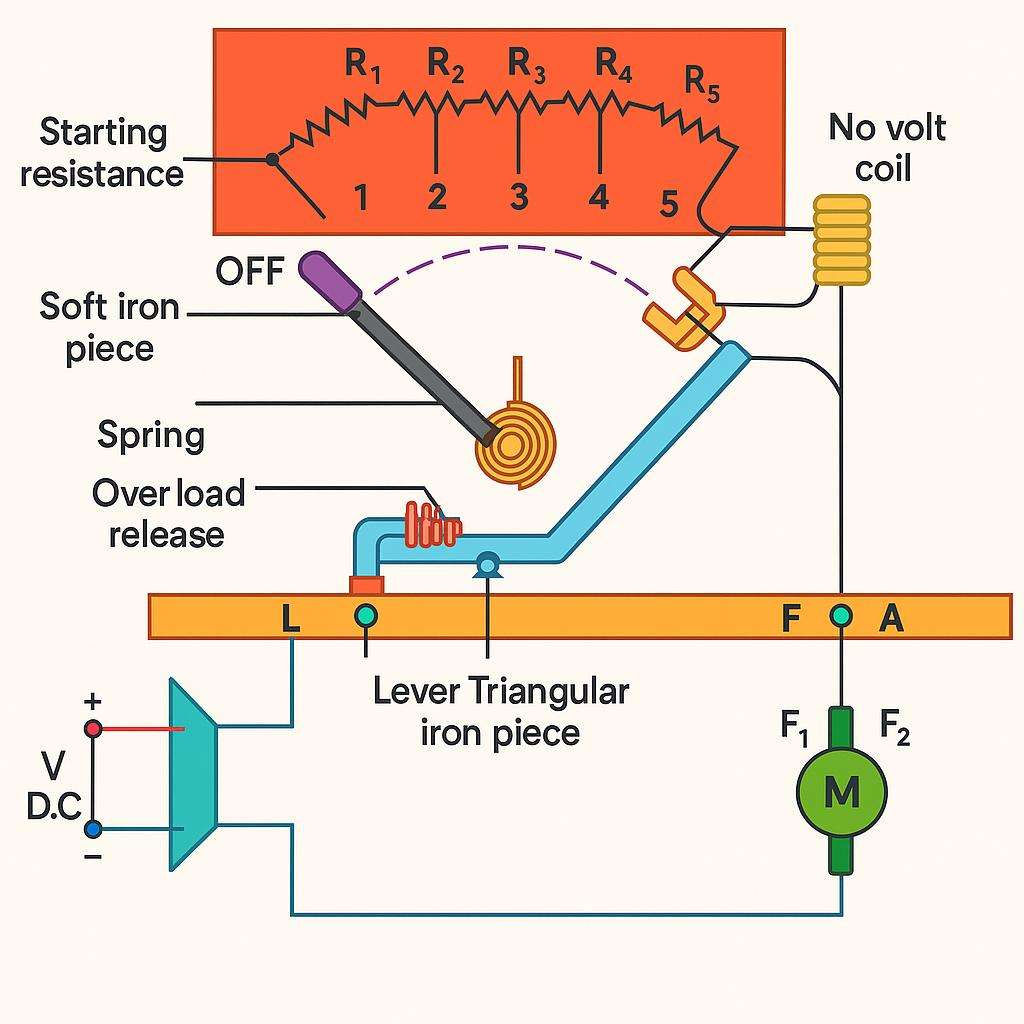

🔌 What is a Three-Point Starter?

A three-point starter is a device used to safely start and stop a DC shunt motor. It also protects the motor from overloads and loss of voltage.

The name “three-point” comes from the three terminals:

- L → Line (incoming supply)

- F → Field winding

- A → Armature winding

🛠️ Main Components and Their Roles

- Starting Arm (SR):

- This is the handle you move to start the motor.

- It’s spring-loaded, so if you let go, it will return to the OFF position unless something holds it in place.

- Starting Resistance (Rs):

- Limits the initial current to the armature. DC motors draw high current at startup, so this protects the motor.

- Studs (Contact Points):

- As the arm moves across these points, it slowly cuts out the resistance in steps.

- By the time it reaches the last stud, all resistance is removed and the motor runs normally.

- Hold-On Coil (NVR – No Voltage Release):

- Acts like a magnet to hold the starter arm in the ON position.

- If the power fails or the field circuit breaks, the coil de-energizes, the magnetic pull is lost, and the arm returns to OFF. This prevents damage to the motor.

- Overload Release (OLR):

- A protective coil connected in the line.

- If the current exceeds safe levels (i.e., overload), it trips, disconnecting the hold-on coil and sending the starter arm back to OFF.

🔄 Step-by-Step Operation

- Power On:

Switch ON the main supply. - Move the Starter Arm (SR):

Begin pushing the arm to the right. As it contacts stud 1:- The field winding gets full supply.

- The armature gets limited current through the full starting resistance.

- Keep Moving the Arm:

- With each step (stud), the resistance in series with the armature reduces.

- This allows the motor to speed up safely.

- Final Stud (ON Position):

- All resistance is removed.

- The Hold-On Coil (NVR) now keeps the arm in place using the current from the field circuit.

- Safety During Faults:

- Power failure or field disconnection → Coil loses power → Arm springs back to OFF.

- Overload → OLR trips → Coil deactivates → Arm goes to OFF.

⚠️ Important Design Note

As the arm moves, part of the resistance is bypassed. If the field current flows through this bypassed resistance, it may drop. So, a brass arc is often used at the first contact to ensure the field circuit gets a steady current directly, avoiding this problem.

Interactive version of this concept

Three-Point Starter Simulation

Simulate the operation of a DC shunt motor with a 3-point starter.

Status: Motor is OFF

Hold-On Coil: De-energized

Overload Protection: Normal

Here are the advantages and disadvantages of a Three-Point Starter used in DC shunt motors:

✅ Advantages of Three-Point Starter

- Protects the Motor During Startup:

- Limits high inrush current to the armature by inserting resistance in series during starting.

- No-Voltage Protection:

- If the supply fails or drops, the Hold-On Coil de-energizes and the arm returns to OFF, preventing accidental restarting.

- Overload Protection:

- The Overload Release trips if the motor draws excess current, preventing overheating or damage.

- Simple and Cost-Effective:

- Mechanically straightforward design that is easy to install and maintain.

❌ Disadvantages of Three-Point Starter

- Field Weakening Risk:

- Since the Hold-On Coil is in series with the field circuit, reducing field current (e.g., for speed control) may unintentionally release the starter arm.

- Manual Operation:

- Requires manual engagement and monitoring; not suitable for automated systems.

- No Reverse Protection:

- It doesn’t prevent motor reversal or handle directional control.

- Limited to DC Shunt Motors:

- Not suitable for series motors or modern AC motor systems.

Would you like a comparison with a Four-Point Starter too?

❓ 1. What is the purpose of a three-point starter?

✅ Answer: A three-point starter is used to safely start and protect a DC shunt motor. It controls the high starting current by gradually cutting out a resistance and also provides protection against overload and voltage drop.

❓ 2. Why is it called a “three-point” starter?

✅ Answer: It is called a three-point starter because it has three main terminals:

L (Line),

F (Field), and

A (Armature).

These points connect to the power supply, field winding, and armature of the motor respectively.

❓ 3. What happens during a power failure?

✅ Answer: During a power failure, the Hold-On Coil (No-Voltage Release) de-energizes. This causes the spring-loaded starter arm to return to the OFF position automatically, stopping the motor and preventing unsafe restarts.

❓ 4. Can the three-point starter be used for speed control?

✅ Answer: No, the three-point starter itself doesn’t control speed. In fact, reducing field current to increase speed can unintentionally weaken the Hold-On Coil, causing the starter to trip. Speed control should be handled separately.

❓ 5. How does the starter protect the motor from overload?

✅ Answer: The starter includes an Overload Release (OLR). If the motor draws too much current, the overload coil trips, deactivates the Hold-On Coil, and the starter arm returns to OFF—thereby disconnecting the motor from the power supply.