Steady Flow Energy Equation

The Steady Flow Energy Equation (SFEE) is a fundamental equation in fluid mechanics and thermodynamics used to analyze the energy changes within a fluid as it undergoes a steady flow process. It is commonly applied to devices such as turbines, pumps, compressors, and nozzles. The equation is derived from the First Law of Thermodynamics, also known as the energy balance equation.

The Steady Flow Energy Equation can be expressed as follows:

Q˙−W˙shaft+m˙(h1+2V1/2+gz1)=m˙(h2+2V2/2+gz2)+W˙device

where:

- ˙Q˙ is the rate of heat transfer into the system (positive for heat addition).

- ˙W˙shaft is the rate of work done by the shaft (positive for work done by the system).

- ˙m˙ is the mass flow rate of the fluid.

- h is the specific enthalpy of the fluid.

- V is the velocity of the fluid.

- g is the acceleration due to gravity.

- z is the elevation above a reference plane.

The terms on the left side of the equation represent the inlet conditions of the fluid, and the terms on the right side represent the outlet conditions. The equation accounts for changes in internal energy, kinetic energy, potential energy, heat transfer, and work.

Key considerations and assumptions for the Steady Flow Energy Equation include:

- Steady flow: The properties at any given point in the system do not change with time.

- Steady state: The system operates at a constant state with time.

- Negligible changes in kinetic and potential energy.

The Steady Flow Energy Equation is a powerful tool for analyzing and designing fluid systems, providing insights into energy transfers and performance characteristics. It is widely used in engineering disciplines such as mechanical, chemical, and aerospace engineering.

Basic Principles of the Steady Flow Energy Equation

The Steady Flow Energy Equation (SFEE) is derived from the First Law of Thermodynamics and is a fundamental tool for analyzing and understanding the energy changes within a fluid as it undergoes a steady flow process. Here are the basic principles underlying the Steady Flow Energy Equation:

- Conservation of Energy:

- The SFEE is based on the principle of the conservation of energy, which states that energy cannot be created or destroyed; it can only change forms. In a steady flow process, the total energy of the fluid (internal energy, kinetic energy, and potential energy) remains constant.

- First Law of Thermodynamics:

- The SFEE is a specific application of the First Law of Thermodynamics, which is the energy balance equation. It accounts for the rate of heat transfer, work done, and changes in internal, kinetic, and potential energy of the fluid.

- Steady Flow Process:

- The SFEE is applicable to steady flow processes, where the properties of the fluid at any given point do not change with time. This allows for a simplified analysis of the energy changes within the system.

- Energy Inlet and Outlet Terms:

- The SFEE includes terms representing the energy conditions at the inlet and outlet of the system. These terms account for the specific enthalpy, kinetic energy, potential energy, heat transfer, and work at both ends of the system.

- Mass Flow Rate:

- The SFEE involves the mass flow rate (˙m˙), representing the rate at which mass flows through the system. This allows the equation to account for the energy changes per unit mass of the fluid.

- Negligible Changes in Kinetic and Potential Energy:

- The SFEE assumes that changes in kinetic and potential energy are negligible. This is often a reasonable assumption for many practical engineering applications, especially when analyzing devices like pumps, turbines, and nozzles.

- Heat Transfer and Work Terms:

- The SFEE includes terms related to heat transfer (˙Q˙) and work done (˙shaftW˙shaft and ˙deviceW˙device). Positive values indicate heat addition to the system and work done by the system, while negative values indicate heat rejection and work done on the system.

- Elevation Reference:

- The elevation terms in the SFEE (z) refer to the elevation above a chosen reference plane. This accounts for changes in potential energy due to differences in height within the system.

- Application in Engineering Systems:

- The SFEE is widely used in engineering disciplines, including mechanical, chemical, and aerospace engineering, to analyze and design systems involving fluid flow, heat transfer, and energy conversion.

- System Efficiency and Performance:

- Engineers use the SFEE to assess the efficiency and performance of devices such as turbines, pumps, and compressors. It provides insights into the energy losses and gains within these systems.

In summary, the Steady Flow Energy Equation provides a systematic and quantitative approach to analyzing energy changes in fluid systems undergoing steady flow processes, making it a valuable tool in engineering applications.

The Role of Steady Flow Energy Equation in Thermodynamics

The Steady Flow Energy Equation (SFEE) plays a crucial role in thermodynamics, particularly in the analysis and understanding of energy transformations within fluid systems undergoing steady flow processes. Here are some key roles and contributions of the SFEE in thermodynamics:

- Conservation of Energy:

- The SFEE is based on the fundamental principle of the conservation of energy. It allows engineers and scientists to apply the principles of thermodynamics to analyze and quantify how energy is conserved within a fluid system during steady flow.

- First Law of Thermodynamics Application:

- The SFEE is a specific application of the First Law of Thermodynamics, providing a quantitative expression of the energy balance equation for a system experiencing steady flow. It allows for a systematic analysis of energy changes involving heat transfer, work done, and changes in internal energy, kinetic energy, and potential energy.

- Engineering System Analysis:

- Engineers use the SFEE to analyze and design various engineering systems, including turbines, pumps, compressors, heat exchangers, and nozzles. It serves as a tool for understanding the energy transfers within these devices and optimizing their performance.

- Efficiency Calculations:

- The SFEE is instrumental in calculating the efficiency of thermodynamic devices. For example, it allows engineers to determine the efficiency of a steam turbine by accounting for the energy input (heat) and energy output (shaft work).

- Heat Exchanger Analysis:

- In heat exchanger design and analysis, the SFEE helps assess the effectiveness of heat transfer and temperature changes within the fluid streams. Engineers can optimize heat exchangers for specific applications using the insights provided by the SFEE.

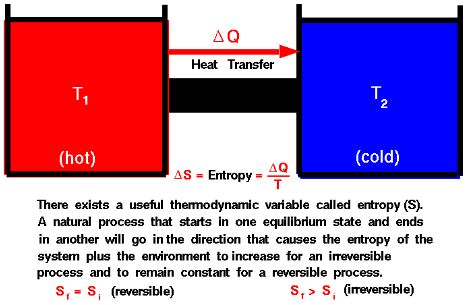

- Understanding Irreversibilities:

- The SFEE aids in identifying irreversibilities within a system. It allows engineers to pinpoint areas of energy losses and inefficiencies, helping in the design of systems with improved performance.

- Thermal Power Plants:

- In the context of thermal power plants, the SFEE is crucial for understanding the energy conversion processes from heat to electricity. Engineers use the SFEE to evaluate the efficiency of power generation cycles.

- Environmental Impact Assessment:

- The SFEE is used in environmental studies and assessments to evaluate the energy efficiency and environmental impact of various processes. It helps identify opportunities for energy conservation and sustainable practices.

- Educational Tool:

- The SFEE serves as a fundamental educational tool in thermodynamics courses. It provides students with a hands-on approach to applying theoretical concepts and principles to real-world engineering problems.

- Research and Development:

- Researchers use the SFEE as a foundational tool for developing new technologies and improving existing ones. It guides the analysis and optimization of energy systems, contributing to advancements in thermodynamics and fluid mechanics.

In summary, the Steady Flow Energy Equation is a versatile and essential tool in thermodynamics, enabling the analysis, design, and optimization of fluid systems and devices. Its application extends across various engineering disciplines, contributing to advancements in energy efficiency and sustainable practices.

Components of the General Energy Equation

The General Energy Equation is a fundamental expression used in fluid mechanics to describe the energy changes within a fluid as it flows through a system. It is derived from the First Law of Thermodynamics and is applicable to both steady and unsteady flow conditions. The general form of the equation is as follows:

∂(ρE)/∂t+∇⋅(ρuE)=−∇⋅q+ρu⋅g+S

Here, ρ is the fluid density, E is the specific total energy per unit mass, u is the velocity vector, q is the heat flux vector, g is the gravitational acceleration vector, and S represents any source or sink terms.

The components of the General Energy Equation are:

- Transient Term:

- ∂(ρE)/∂t

- Represents the rate of change of total energy with respect to time. It accounts for transient effects during unsteady flow conditions.

- Convective Term:

- ∇⋅(ρuE)

- Describes the convective transport of energy due to fluid motion. It represents the change in energy associated with the movement of fluid elements.

- Dissipation Term (Heat Conduction):

- ∇⋅q

- Accounts for the heat conduction within the fluid. The negative sign indicates that heat is conducted from regions of higher temperature to lower temperature.

- Potential Energy Term:

- ρu⋅g

- Represents the change in potential energy of the fluid due to its elevation in a gravitational field. It accounts for the work done against gravity.

- Source/Sink Term:

- S

- Includes any additional terms representing sources or sinks of energy within the system. This could include external heat sources, work done by external forces, or other forms of energy input or extraction.

The General Energy Equation is a comprehensive expression that provides insights into the various mechanisms influencing the energy content of a fluid as it moves through a system. It is particularly useful for analyzing complex flow situations where multiple energy transfer processes are involved.

It’s worth noting that in certain scenarios, specific simplifications or assumptions may lead to variations of the General Energy Equation tailored to particular applications, such as the Steady Flow Energy Equation for steady flow conditions or the Euler Equation for inviscid flow.

Frequently Asked Questions

1.What is the Steady Flow Energy Equation (SFEE) in fluid mechanics?

The SFEE is a fundamental equation that accounts for the energy changes within a fluid as it undergoes a steady flow process. It is derived from the First Law of Thermodynamics and is widely used in the analysis of devices such as turbines, pumps, and compressors.

2.What does “steady flow” mean in the context of the SFEE?

A: “Steady flow” refers to the condition where the properties of the fluid at any given point do not change with time. In the SFEE, this assumption simplifies the analysis of energy changes within the system.

3.How is the SFEE different from the General Energy Equation?

While the General Energy Equation is more comprehensive and applicable to both steady and unsteady flow, the SFEE specifically focuses on steady flow conditions. It simplifies the equation by excluding terms related to transient effects.

4.What are the main components of the SFEE?

The SFEE includes terms representing energy changes due to heat transfer, work done by external forces, kinetic energy variations, potential energy changes, and frictional effects. The equation provides a systematic account of these components.

5.Can the SFEE be applied to analyze real-world devices?

Yes, the SFEE is commonly used in engineering to analyze and design devices involving fluid flow, such as pumps, turbines, and nozzles. It helps assess the energy transformations and efficiency of these devices.

6.How does the SFEE account for work done by the fluid in a device?

The SFEE includes terms related to the work done by the fluid, both on the device (e.g., a pump) and by the device (e.g., a turbine). These terms contribute to the overall energy balance.

7.Is the SFEE applicable to compressible fluids as well?

Yes, the SFEE is applicable to both incompressible and compressible fluids. It accommodates variations in fluid density and velocity, making it versatile for a range of fluid flow scenarios.

8.Does the SFEE consider losses due to friction and irreversibilities?

Yes, the SFEE accounts for losses due to friction and irreversibilities through terms like the head loss term. Engineers use this information to assess the efficiency of devices and systems.

9.Can the SFEE be used to calculate the efficiency of a pump or a turbine?

Yes, the SFEE is instrumental in calculating the efficiency of pumps, turbines, and other devices. Efficiency is often expressed as the ratio of useful work done by the device to the energy input.

10.What assumptions are made when applying the SFEE to practical problems?

Common assumptions include steady flow, neglecting kinetic and potential energy changes (unless specified otherwise), and accounting for losses due to friction and other irreversibilities.