Milling Machine:

Milling Machine: Milling is one of the types of cutting machine which is used for various types of operations on it. The milling machine is operated with the help of an electric motor which is connected to a spindle of the cutting tool to produce high rotational speed to remove the extra material from work. on this type of machine, we can work on small parts and large parts. We can operate various types of operations on this machine like angular, form, face, up and down milling, etc.

In this type of operation, the workpiece used to feed against the cutting tool which makes the high rotational speed at a fixed center. In this type of machining operation, there are different types of cutters used in milling operations and in cutting tools of the milling machine the number of teeth on it depends on the circumference of a cutting tool.

Milling Machine Operation:

All the milling machines are used to cut/remove the extra material from a workpiece to obtain a required product. First, the supply of electricity is needed to run the motor with the help of this, spindle makes rotation with high speed due to the connection between them. for further rotation of the cutting tool, the spindle is connected to cutting tool holder. In some of the milling machines, we can move the spindle in different directions according to the work required. we need to feed the work towards the cutting tool, in most of the milling machine process work gets completed in one pass towards the cutting tool due to the cutting tool consist of more than two cutters on it. In this type of machine, we can adjust the knee and there is a need of cooling oil due to continuous cutting and fast rate.

Types of milling cutters:

- Cylindrical cutting tool

- Angle cutting tool

- End cutting tool

- T-slot Cutter

- Form cutter

In this type of milling operation, we need to select the required cutting tool according to the machining process and there is also a need to consider the properties of work material like strength, hardness, temperature resistance, mechanical properties, etc. There are different types of milling machines which is used to work differently. there are various machines that contain different cutting tools, work holding tables.

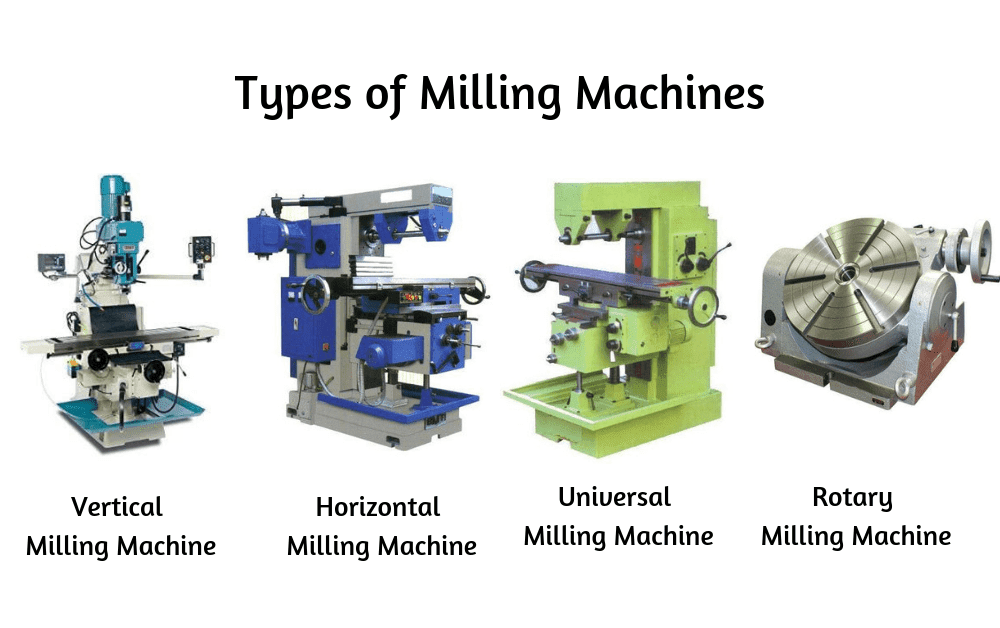

Diferent Types of Milling Machines:

Vertical Milling Machine:

Vertical Milling Machine is one of the most popular and most used operation methods. In Vertical Milling Machine, there is a multi-point cutting tool called milling cutter. this machine has a vertical spindle that is perpendicular to the workpiece. In Vertical Milling Machine, the head is used to swiveled or it can be fixed. This can move in upward and downward directions and can move in any direction. Vertical Milling Machine is used to make a different type of operation like a flat surface, grooves, slots, etc.

Read more about: VERTICAL MILLING MACHINE: WORKING, MAIN PARTS, ADVANTAGES OF VERTICAL MILLING MACHINE

Horizontal Milling Machine:

Horizontal milling machine contains a long base and over this, it has a screw jack to move the knee in a vertical direction. the knee carries the saddle over it which helps to move the work table to and fro motion. In this machine, there is a motor to rotate the cutting tool which is fixed to the arbor. the motor which runs with the supply of electricity.

Universal Milling Machine:

This type of milling machine contains the same spindle related to horizontal type, in this type of machine base is in a circular shape on which saddle is carried to hold the work table and helps to move the table in the required angle, which is possible up to 45 degrees.

Related Topics:

Difference between horizontal and vertical milling machine

Omniversal Milling Machine:

In this type of machine, the base of the machine is attached with the knee to provide a rotational moment and with the help of an elevating screw, we can adjust it. and the work table is carried over the swivel base which helps to move in different directions.

Rise and Fall Milling Machine:

In this type of milling machine, there are less moving parts init. we can move only the work table which is in one direction and the cutting tool used to rotate at a horizontal position and moves in a vertical direction.

Turret Milling Machine:

This type of machining process is a little different one compared to other types. in this, we can use two different types of cutting tools and operate them simultaneously. in this machine, the knee is on the base which can be moved up and down and the table on the knee can be moved in opposite to knee.

Rotary Milling Machine:

A rotary milling machine is an advanced type in a vertical milling machine. in this machining process, we can fix two cutting tools and different numbers of works on the table. the cutting tools used to rotate in a fixed vertical axis. the table used to rotate at a fixed axis. in this machining process, we can operate two works at a time.

These milling machines are used according to the manufacturing of a product needed in different industries. Due to the different types of the milling machine and cutting tool are in existence this type of machining is widely used in many industries. due to different factors, there are some effects caused by the operation process.

Main parts of milling machine:

Base:

The base is the bottom part of a machine used to support the machine and in some of the milling machines contains coolant in it. the coolant used to recirculate from base to moving parts in milling machines

Column:

The column is mounted on the top of the base, this is used to support the knee by the help of guideways and on the top of it, ram is located. and there is an arrangement of an electric motor in it, which used to rotate the spindle and makes the cutting tool rotate.

Saddle:

This is present at the front of the column. this is used to carry the worktable on which work is done.and in some machines the saddle can move in different directions to make work easy and makes the cutting tool to reach easily.

Knee:

The knee is present at the bottom of the saddle this is used to support the table and can adjust its position according to the operation.

Table:

The table is used to hold the workpiece on it and this can make the longitudinal motion. this table contains work hold devices that are stronger and more rigid in construction due to this must support high vibrations.

Ram:

This on the top of the column to make a required angle at the time of cutting.

Tool Head:

This is to hold the tool holder in which the tool is fixed.

Spindle:

This is located in the head which is used to make the rotation with the help of motors present in the column. and there are different types to hold different cutting tools in it. some of the milling machines contain more than one which makes it easy at work.

Effects at milling operations:

- A milling machine cannot work at less speed of a spindle.

- Due to the high rotational speed of cutting tool work should hold strongly at the work table.

- This type of machining operation needs more coolant oil.

- In some types of milling operations cutting tool undergoes to huge stresses.