Destructive Testing:

Destructive Testing: Destructive testing is done to measure the strength, toughness, brittleness etc.. of the metals. Destructive tests are carried out under different machines like universal testing machines, impact testing machine etc.

Tensile testing:

A tensile test is used to find the strength of the metal by using a universal testing machine. The strength can be calculated by measurements of metal and load applied, once the workpiece/specimen is placed in a machine, the load applied on the workpiece can be increased gradually, by this workpiece used to elongate up to the maximum strength of the metal, This elongation limit is called elastic range. at some point, the metal gets fractured after reaching the maximum stress. before this fracture, the maximum stress is obtained by the metal is called ultimate strength.

Read About: NON-DESTRUCTIVE TESTING

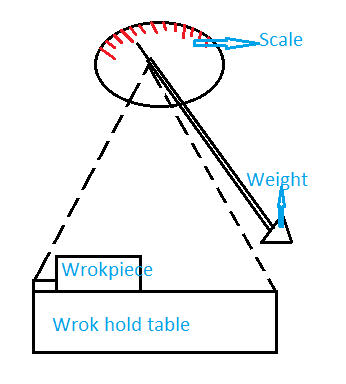

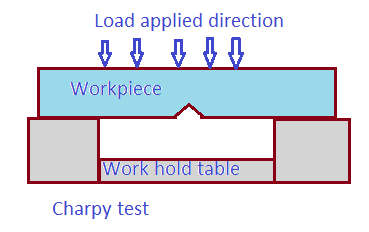

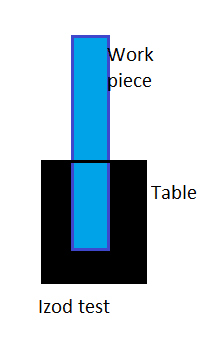

Impact Test:

This type of testing is used to find the toughness of metal by using an impact test machine. in this process, there are two methods like Charpy test and Izod test.To test the work-piece/specimen notched bar should be done according to the standards when the work-piece is placed in the path of a lever attached with weight as shown in the figure, it hits the work-piece and breaks when the lever is lifted to a known height and realized, the amount of energy absorbed by the weld behind the fracture acquired is an impact load.

Impact test

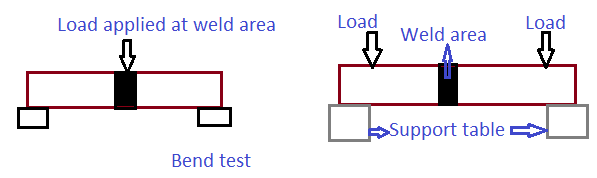

Bend Test:

This type of test is used to find the brittleness of the metal, by using the simple beam equation the strength can be known. this method is done by applying the load at weld point or at two different points with vertical force on it.