What is Actual Vapour Compression Cycle?

The actual vapor compression cycle refers to the real-world operation of a vapor compression refrigeration or air conditioning system, taking into account various factors that deviate from the theoretical ideal cycle. Unlike the theoretical vapor compression cycle, which assumes perfect and reversible processes, the actual cycle considers the practical limitations, inefficiencies, and losses inherent in real-world systems.

Here are some key aspects and factors that differentiate the actual vapor compression cycle from the theoretical ideal cycle:

- Compressor Efficiency:

- In actual systems, compressors are not perfectly efficient. Mechanical and volumetric inefficiencies, as well as losses due to friction and heat, result in deviations from the isentropic compression process assumed in the ideal cycle.

- Heat Exchanger and Condenser Realities:

- Real-world condensers and evaporators may experience non-uniform heat transfer, pressure drops, and fouling, affecting their performance. These deviations from ideal behavior are considered in the actual cycle.

- Throttling Device and Expansion Valve Efficiency:

- The expansion process through the throttling device or expansion valve is not perfectly adiabatic, and there are losses associated with the expansion. These losses are considered in the actual cycle.

- Refrigerant Property Changes:

- The properties of the refrigerant, such as its superheat and subcooling values, may not align precisely with theoretical assumptions. Actual refrigerants may exhibit some deviation from ideal behavior.

- Heat Exchanger Irreversibilities:

- Irreversibilities in heat exchangers, including temperature differences, thermal gradients, and non-ideal heat transfer, impact the actual cycle.

- Leakages and Infiltration:

- Refrigerant leakages and non-condensable gas infiltration into the system can occur in real-world scenarios, affecting system efficiency and performance.

- Compressor Clearance Volume:

- The existence of clearance volumes in compressors introduces inefficiencies during the compression process, as some of the previously compressed gas is not expelled during the subsequent suction stroke.

- Oil Circulation and Lubrication:

- Compressors may require lubrication, and the circulation of oil within the system introduces additional complexities and considerations, impacting the actual cycle.

- Transient and Dynamic Effects:

- Real-world systems experience transient and dynamic effects during startup, shutdown, and variable operating conditions. These effects, such as cycling losses, impact the overall system performance.

- Control Strategies:

- The actual vapor compression cycle considers the impact of control strategies, such as on-off cycling of compressors and modulation of system components, on efficiency and energy consumption.

Understanding the actual vapor compression cycle is crucial for system designers, engineers, and technicians to optimize performance, diagnose issues, and improve the efficiency of refrigeration and air conditioning systems in practical applications. Researchers and practitioners use experimental data, computer simulations, and advanced modeling techniques to analyze and characterize the actual performance of these systems.

What is the Actual Vapour Compression Cycle Process

The actual vapor compression cycle in a refrigeration or air conditioning system consists of several processes that deviate from the idealized, theoretical cycle. In real-world applications, factors such as compressor inefficiencies, heat exchanger losses, refrigerant property variations, and other practical considerations impact the performance of the cycle. Here is an overview of the processes in the actual vapor compression cycle:

- Compression (Process 1-2a):

- The process begins with the compression of the refrigerant vapor by the compressor. In actual systems, the compression process is not perfectly isentropic (adiabatic and reversible), as assumed in the ideal cycle.

- Factors such as mechanical inefficiencies, clearance volumes, and heat losses result in a departure from ideal compression.

- Discharge Line and Heat Rejection (Process 2a-2b):

- After compression, the high-pressure, high-temperature refrigerant enters the discharge line and then the condenser.

- In the condenser, heat is rejected to the surroundings as the refrigerant undergoes a phase change from vapor to liquid. Heat exchanger inefficiencies, subcooling, and non-uniform heat transfer affect the actual condensation process.

- Expansion (Process 2b-3):

- The high-pressure liquid refrigerant passes through the expansion valve or throttling device, causing a significant pressure drop. The expansion process is not perfectly adiabatic in actual systems.

- The refrigerant exits the expansion device as a low-pressure, low-temperature mixture of liquid and vapor.

- Evaporation and Heat Absorption (Process 3-4a):

- In the evaporator, the low-pressure refrigerant absorbs heat from the surroundings (cooling space) and undergoes phase change from liquid to vapor.

- Factors such as heat exchanger inefficiencies, superheat, and non-uniform heat transfer influence the actual evaporation process.

- Suction Line and Heat Absorption (Process 4a-4b):

- The low-pressure vapor refrigerant returns to the compressor through the suction line, where it is further heated before entering the compressor.

- Heat absorbed in the suction line affects the vapor entering the compressor.

The processes described above represent one cycle, and the cycle repeats as long as the refrigeration or air conditioning system is operational. The actual vapor compression cycle accounts for the real-world complexities and deviations from ideal behavior, and engineers use experimental data, modeling, and simulation to analyze and optimize the performance of these systems. Understanding the actual cycle is crucial for designing efficient systems, diagnosing issues, and improving overall system performance.

Advantages of Actual Vapour Compression Cycle

The actual vapor compression cycle in refrigeration and air conditioning systems offers several advantages over the idealized, theoretical vapor compression cycle. Despite the deviations from ideal behavior, the actual cycle reflects real-world conditions and considerations, leading to practical benefits in system design, performance, and operation. Here are some advantages of the actual vapor compression cycle:

- Realistic Performance Evaluation:

- The actual vapor compression cycle provides a more realistic representation of system performance by accounting for factors such as compressor inefficiencies, heat exchanger losses, and refrigerant property variations. This allows for a more accurate assessment of system behavior under real-world operating conditions.

- Improved System Design:

- Understanding the actual cycle enables engineers to design refrigeration and air conditioning systems that account for practical considerations, resulting in more efficient and reliable designs. This includes selecting appropriate components, optimizing system configurations, and meeting specific application requirements.

- Optimized Energy Efficiency:

- By considering the actual performance characteristics of system components, engineers can optimize the energy efficiency of vapor compression cycles. This may involve improving compressor design, enhancing heat exchanger performance, and implementing advanced control strategies to minimize energy consumption.

- Enhanced System Control:

- Knowledge of the actual cycle allows for the development of advanced control algorithms and strategies tailored to real-world operating conditions. This facilitates precise control of system parameters such as temperature, pressure, and flow rates, leading to improved system stability and performance.

- Accurate Performance Prediction:

- The actual vapor compression cycle enables engineers to accurately predict system performance and behavior, taking into account factors such as transient effects, dynamic response, and off-design operation. This aids in the design, analysis, and optimization of refrigeration and air conditioning systems.

- Effective Troubleshooting:

- Understanding the actual cycle helps technicians diagnose and troubleshoot issues more effectively by identifying potential sources of inefficiency, malfunction, or performance degradation. This leads to quicker problem resolution and reduced downtime for the system.

- Adaptability to Variable Conditions:

- The actual vapor compression cycle is more adaptable to variable operating conditions, including changes in ambient temperature, load variations, and system dynamics. This allows for greater flexibility and robustness in system performance across different operating scenarios.

- Improved Reliability and Durability:

- By accounting for real-world factors and practical considerations, the actual vapor compression cycle contributes to the design of more reliable and durable refrigeration and air conditioning systems. This leads to longer system lifespans and reduced maintenance requirements.

- Environmental Considerations:

- Optimizing the actual vapor compression cycle can lead to reduced environmental impact by minimizing energy consumption, refrigerant usage, and greenhouse gas emissions. This aligns with sustainability goals and regulatory requirements related to energy efficiency and environmental protection.

- Cost Savings:

- By designing and operating more efficient and reliable systems based on the actual cycle, organizations can realize cost savings through reduced energy bills, lower maintenance expenses, and extended equipment lifespans.

In summary, the actual vapor compression cycle offers numerous advantages that contribute to the efficient, reliable, and sustainable operation of refrigeration and air conditioning systems in various applications. By understanding and optimizing the actual cycle, engineers and technicians can achieve superior performance and cost-effective solutions tailored to specific needs and requirements.

Disadvantages of Actual Vapour Compression Cycle

While the actual vapor compression cycle provides a more realistic representation of real-world conditions in refrigeration and air conditioning systems, it also comes with certain disadvantages. These drawbacks stem from the practical limitations, inefficiencies, and deviations from ideal behavior that are inherent in actual systems. Here are some disadvantages of the actual vapor compression cycle:

- Lower Efficiency Compared to Ideal Cycle:

- The actual cycle is inherently less efficient than the idealized, theoretical vapor compression cycle. Factors such as compressor inefficiencies, heat exchanger losses, and irreversibilities contribute to reduced overall system efficiency.

- Increased Energy Consumption:

- Inefficiencies in the actual vapor compression cycle result in higher energy consumption compared to the ideal cycle. This can lead to increased operational costs and energy bills for the user.

- Complex Modeling and Analysis:

- Analyzing and modeling the actual vapor compression cycle is more complex than dealing with the idealized cycle. It requires consideration of various factors such as non-uniform heat transfer, transient effects, and system dynamics, making the analysis more challenging.

- Component Wear and Maintenance:

- The actual cycle may involve more wear and tear on system components due to factors like compressor inefficiencies and non-ideal heat transfer. This can lead to increased maintenance requirements and potential downtime for repairs.

- Limited System Flexibility:

- Deviations from ideal behavior in the actual cycle may limit the flexibility of the system to adapt to varying operating conditions. This can affect the system’s performance under different loads, temperatures, and other environmental factors.

- Higher Environmental Impact:

- Inefficient operation in the actual cycle may result in increased environmental impact, particularly if the system uses refrigerants with high global warming potential (GWP). Higher energy consumption can contribute to greater greenhouse gas emissions.

- Reduced System Lifespan:

- The additional stresses on components caused by inefficiencies in the actual cycle may contribute to a shorter overall system lifespan. Components may experience more rapid wear, potentially leading to more frequent replacements.

- Potential for System Instabilities:

- Non-ideal behavior in the actual cycle, especially during transient conditions, may introduce instabilities into the system. This can manifest as temperature fluctuations, pressure variations, and other undesirable effects.

- Challenges in System Control:

- The actual vapor compression cycle may present challenges in control due to factors such as varying compressor efficiency and non-uniform heat transfer. Achieving precise control of system parameters can be more difficult.

- Higher Initial Costs for Advanced Components:

- Implementing components and technologies that mitigate the disadvantages of the actual cycle, such as more efficient compressors or advanced heat exchangers, may result in higher initial costs for system installation or upgrades.

Despite these disadvantages, advancements in technology, system design, and control strategies aim to mitigate the impact of non-ideal behavior in actual vapor compression cycles. Engineers and researchers continually work to improve system efficiency, reliability, and environmental sustainability.

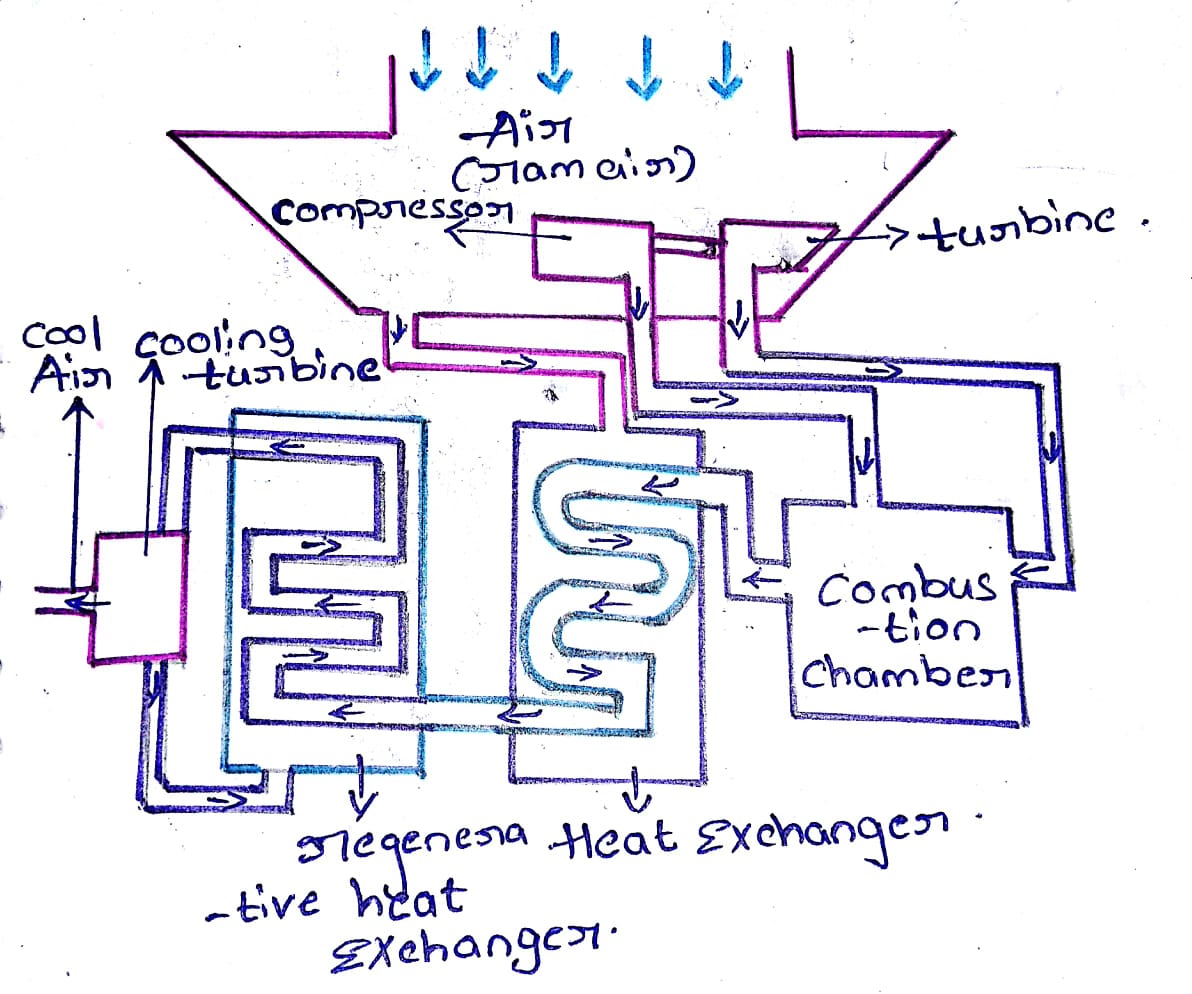

Working Principle Of Actual Vapour Compression Cycle

The vapor compression cycle is a thermodynamic process used in refrigeration and air conditioning systems to transfer heat from a lower temperature space (evaporator) to a higher temperature space (condenser). The cycle involves four main processes: compression, condensation, expansion, and evaporation. Here’s a detailed explanation of the working principle of the vapor compression cycle:

- Compression (Process 1-2):

- The cycle begins with the compressor, which takes low-pressure, low-temperature vapor refrigerant from the evaporator and compresses it to a higher pressure and temperature.

- The compressor increases the enthalpy of the refrigerant, raising both its pressure and temperature. The compression process is typically assumed to be adiabatic and reversible in idealized models.

- Condensation (Process 2-3):

- The high-pressure, high-temperature vapor refrigerant exits the compressor and enters the condenser. In the condenser, heat is rejected to the surroundings, causing the refrigerant to undergo a phase change from vapor to liquid.

- The condenser operates at a constant pressure, and the refrigerant releases latent heat as it changes phase. The refrigerant leaves the condenser as a high-pressure liquid.

- Expansion (Process 3-4):

- The high-pressure liquid refrigerant flows through the expansion valve or throttling device, experiencing a significant drop in pressure.

- The expansion process is adiabatic, causing the refrigerant to transition to a low-pressure, low-temperature mixture of liquid and vapor.

- Evaporation (Process 4-1):

- The low-pressure refrigerant enters the evaporator, where it absorbs heat from the surroundings (cooling space) and undergoes a phase change from liquid to vapor.

- The evaporator operates at a constant pressure, and the refrigerant absorbs latent heat, cooling the space. The refrigerant leaves the evaporator as a low-pressure vapor, and the cycle repeats.

During these processes, the refrigerant acts as the working fluid, and the cycle facilitates the transfer of heat from the evaporator (cooling space) to the condenser (outside environment). The compressor plays a crucial role in raising the pressure and temperature of the refrigerant, enabling efficient heat transfer in the condenser. The expansion valve or throttling device causes a pressure drop, leading to cooling in the evaporator.

In practical applications, the vapor compression cycle is subject to various real-world factors, including compressor inefficiencies, heat exchanger losses, and non-ideal behaviors. These factors are considered in the actual vapor compression cycle, which may deviate from the idealized model. Engineers design and optimize systems based on these principles to achieve efficient and reliable refrigeration and air conditioning.

Applications Of Actual Vapour Compression Cycle

The actual vapor compression cycle finds extensive applications in various industries and sectors due to its effectiveness in providing cooling and refrigeration. Despite the practical limitations and deviations from ideal behavior, the actual vapor compression cycle is widely employed in diverse applications.

Here are some key applications:

- Refrigeration Systems:

- Actual vapor compression cycles are commonly used in household refrigerators, commercial refrigeration units, and industrial refrigeration systems for preserving food, beverages, and other perishable goods.

- Air Conditioning Systems:

- The cycle is a fundamental principle in air conditioning systems for cooling and dehumidifying indoor spaces, including residential, commercial, and industrial buildings.

- Process Cooling:

- In industrial processes, the actual vapor compression cycle is used for cooling applications, such as maintaining temperature control in manufacturing processes, chemical production, and various industrial applications.

- Cold Storage Facilities:

- Actual vapor compression cycles are employed in cold storage warehouses and facilities to maintain low temperatures for long-term storage of goods, including frozen foods, pharmaceuticals, and biological samples.

- Food and Beverage Industry:

- Applications include cooling processes in food and beverage production, such as chilling liquids, freezing products, and maintaining specific temperature conditions in processing and storage.

- HVAC (Heating, Ventilation, and Air Conditioning):

- The cycle is a foundational principle in HVAC systems, providing both cooling and heating capabilities to control the temperature and air quality in residential, commercial, and institutional buildings.

- Data Center Cooling:

- Actual vapor compression cycles are used in cooling systems for data centers to dissipate the heat generated by servers and electronic equipment, ensuring optimal operating conditions.

- Medical Refrigeration:

- The cycle is employed in medical refrigeration applications, including the storage of vaccines, pharmaceuticals, and biological samples in healthcare facilities and laboratories.

- Automotive Air Conditioning:

- Vapor compression cycles are utilized in automotive air conditioning systems to cool the interior of vehicles, providing comfort to passengers.

- Ice Production:

- The cycle is used in ice-making machines for producing ice in various forms, such as ice cubes and crushed ice, for commercial and residential use.

- Beverage Dispensing Systems:

- In applications like soda fountains and beer dispensers, vapor compression cycles are used for cooling beverages before dispensing.

- Wine Cellars:

- Actual vapor compression cycles contribute to temperature control and humidity regulation in wine cellars to ensure proper storage conditions for wines.

- Chemical and Petrochemical Industries:

- Vapor compression cycles are employed for cooling processes in chemical and petrochemical industries, such as maintaining temperature control in reaction vessels and distillation columns.

- Environmental Chambers:

- In research and testing facilities, vapor compression cycles are used to create controlled environmental conditions for testing materials, equipment, and products.

The widespread adoption of the actual vapor compression cycle in these applications highlights its versatility and efficiency in meeting diverse cooling and refrigeration needs across various industries. Engineers and designers continually refine and optimize systems based on the principles of the vapor compression cycle to enhance performance, energy efficiency, and sustainability.

Frequently Asked Questions – FAQ’s

How can the actual vapor compression cycle be optimized for specific applications?

Optimization involves selecting efficient components, employing advanced control strategies, choosing environmentally friendly refrigerants, minimizing heat exchanger losses, and adapting the system design to meet the specific requirements of the application.

How does the actual cycle differ from the ideal vapor compression cycle?

The actual cycle considers factors like compressor inefficiencies, heat exchanger losses, and non-ideal behaviors, whereas the idealized cycle assumes perfect and reversible processes with no losses.

What is the actual vapor compression cycle?

The actual vapor compression cycle is a thermodynamic process used in refrigeration and air conditioning systems, incorporating real-world factors and deviations from the idealized, theoretical cycle to achieve practical and efficient cooling.

What role does the compressor play in the actual cycle?

The compressor raises the pressure and temperature of the refrigerant, facilitating efficient heat transfer in the condenser. However, in actual systems, compressors may experience inefficiencies, affecting the overall efficiency of the cycle.

How does the actual vapor compression cycle contribute to energy efficiency?

The cycle contributes to energy efficiency through optimization of components, control strategies, and system design, despite the inherent inefficiencies. Efforts to reduce energy consumption and improve overall performance are key considerations.

Where is the actual vapor compression cycle commonly applied?

It is commonly applied in refrigeration systems, air conditioning systems, process cooling, cold storage facilities, food and beverage industry, HVAC systems, data center cooling, medical refrigeration, automotive air conditioning, and various industrial applications.

What are the disadvantages of the actual vapor compression cycle?

Disadvantages include lower efficiency compared to the ideal cycle, increased energy consumption, complex modeling and analysis, potential for component wear and maintenance, limited system flexibility, higher environmental impact, reduced system lifespan, potential for system instabilities, challenges in system control, and higher initial costs for advanced components.

What are the advantages of the actual vapor compression cycle?

Advantages include realistic performance evaluation, improved system design, optimized energy efficiency, enhanced system control, accurate performance prediction, effective troubleshooting, adaptability to variable conditions, improved reliability and durability, environmental considerations, and potential cost savings.

How does the actual vapor compression cycle impact environmental sustainability?

Efforts to optimize the actual cycle contribute to reduced energy consumption and environmental impact. The use of environmentally friendly refrigerants and sustainable practices align with efforts to enhance environmental sustainability.

What are the main components of the actual vapor compression cycle?

The main components include the compressor, condenser, expansion device, evaporator, piping, heat exchangers, refrigerant, oil separator (in some systems), oil management system, and control system.