Difference between a Heat engine ,Refrigerator and Heat pump

The distinctions between a heat engine, refrigerator, and heat pump lie in their functions, goals, and the direction of energy transfer. Here are the key differences:

- Heat Engine:

- Function: A heat engine is a device that converts heat energy into mechanical work. It operates in a cyclic manner, taking in heat from a high-temperature reservoir, performing work, and rejecting waste heat to a low-temperature reservoir.

- Goal: The primary goal of a heat engine is to produce mechanical work, such as turning a turbine or generating electricity.

- Refrigerator:

- Function: A refrigerator is a device that transfers heat from a low-temperature space (inside the refrigerator) to a high-temperature space (outside the refrigerator). It operates in a cyclic manner and uses a refrigeration cycle to cool the interior.

- Goal: The main goal of a refrigerator is to maintain a low temperature inside and preserve or cool the contents.

- Heat Pump:

- Function: A heat pump is similar to a refrigerator but has a dual function. It can transfer heat from a low-temperature space to a high-temperature space (heating mode) or extract heat from a high-temperature space and release it to a low-temperature space (cooling mode).

- Goal: The primary goal of a heat pump is to provide either heating or cooling for a space, depending on the mode of operation.

Key Differences:

- Energy Flow:

- In a heat engine, the energy flow is from a high-temperature reservoir to a low-temperature reservoir, producing work in the process.

- In a refrigerator, the energy flow is from the interior (low-temperature space) to the exterior (high-temperature space), absorbing heat to cool the interior.

- In a heat pump, the energy flow can be reversible, transferring heat in both directions, depending on the operational mode.

- Work Output:

- A heat engine is designed to produce work output (mechanical work) as its primary function.

- A refrigerator and a heat pump focus on transferring heat to achieve cooling or heating rather than producing mechanical work.

- Cyclic Operation:

- Heat engines and refrigerators operate in a cyclic manner, continuously repeating a series of processes to achieve their goals.

- A heat pump also operates in a cyclic manner but with the flexibility to change its mode between heating and cooling.

- Temperature Reservoirs:

- Heat engines operate between a high-temperature reservoir (source) and a low-temperature reservoir (sink).

- Refrigerators and heat pumps operate between an interior (low-temperature space) and an exterior (high-temperature space).

Understanding these differences highlights the diverse applications and functions of these thermodynamic systems based on their specific goals and energy transfer directions.

Certainly, here’s a table summarizing the key differences between a heat engine, refrigerator, and heat pump:

| Characteristic | Heat Engine | Refrigerator | Heat Pump |

|---|---|---|---|

| Function | Converts heat energy into mechanical work. | Transfers heat from a low-temperature space to a high-temperature space. | Transfers heat bidirectionally: from low to high temperature (heating mode) or from high to low temperature (cooling mode). |

| Goal | Produces mechanical work. | Maintains a low temperature inside, preserving or cooling contents. | Provides heating or cooling for a space, depending on the mode of operation. |

| Energy Flow | From high-temperature reservoir to low-temperature reservoir, producing work. | From interior (low-temperature space) to exterior (high-temperature space), absorbing heat to cool the interior. | Reversible; can transfer heat in both directions, depending on the operational mode. |

| Work Output | Produces mechanical work. | Focuses on transferring heat to achieve cooling. | Focuses on transferring heat bidirectionally for heating or cooling purposes. |

| Cyclic Operation | Yes, operates in a cyclic manner. | Yes, operates in a cyclic manner. | Yes, operates in a cyclic manner, with reversible modes for heating and cooling. |

| Temperature Reservoirs | Operates between a high-temperature reservoir (source) and a low-temperature reservoir (sink). | Operates between an interior (low-temperature space) and an exterior (high-temperature space). | Operates between an interior (low-temperature space) and an exterior (high-temperature space) in both heating and cooling modes. |

This table highlights the distinct characteristics and purposes of each thermodynamic system, emphasizing their specific roles in energy transfer and utilization.

What is Heat Engine?

A heat engine is a device that converts heat energy obtained from a high-temperature source into mechanical work. It operates on the principles of thermodynamics, specifically the conversion of heat into useful work through a cyclic process. Heat engines play a crucial role in various applications, from power generation to transportation.

Here are the key features and components of a heat engine:

- High-Temperature Source:

- A heat engine operates between two temperature reservoirs – a high-temperature source and a low-temperature sink. The high-temperature source provides thermal energy to the system.

- Working Substance:

- The engine utilizes a working substance, often a gas or fluid, which undergoes a thermodynamic cycle. Common working substances include steam in steam engines, gas in internal combustion engines, or refrigerants in some types of heat engines.

- Thermodynamic Cycle:

- The working substance undergoes a cyclic process, typically involving compression, heat addition, expansion, and heat rejection. The most common thermodynamic cycles used in heat engines are the Rankine cycle (for steam engines) and the Otto or Diesel cycles (for internal combustion engines).

- Mechanical Work:

- During the thermodynamic cycle, the working substance performs mechanical work, such as moving a piston in a reciprocating engine or turning a turbine in a steam or gas turbine.

- Heat Rejection:

- After performing work, the working substance releases excess heat to the low-temperature sink. This heat rejection completes the cycle and prepares the substance for the next cycle.

- Efficiency:

- The efficiency of a heat engine is defined as the ratio of the useful work output to the heat input. The Carnot efficiency represents the maximum possible efficiency for a heat engine operating between two temperature reservoirs.

- Applications:

- Heat engines are employed in various applications, including power plants, automotive engines, aircraft propulsion systems, and industrial machinery. They play a central role in converting thermal energy into useful mechanical work.

It’s important to note that no heat engine can be 100% efficient due to the second law of thermodynamics, which states that some energy will always be lost as waste heat during the energy conversion process. The efficiency of real-world heat engines is influenced by factors such as friction, heat losses, and irreversibilities in the thermodynamic processes.

Advantages of Heat Engine

Heat engines offer several advantages, and their widespread use is attributed to their ability to efficiently convert heat energy into mechanical work. Here are some key advantages of heat engines:

- Energy Conversion:

- Heat engines provide an efficient means of converting thermal energy (heat) into mechanical work, allowing for the utilization of various heat sources to produce useful power.

- Versatility:

- Heat engines can operate using a variety of heat sources, including fossil fuels, biomass, solar energy, geothermal energy, and nuclear energy. This versatility makes them adaptable to different energy generation scenarios.

- Widespread Applications:

- Heat engines are employed in diverse applications, ranging from power plants generating electricity to propulsion systems in vehicles, ships, and aircraft. Their versatility makes them integral to many industries.

- High Power Density:

- Many heat engines exhibit high power density, meaning they can produce a significant amount of power relative to their size and weight. This characteristic is valuable in applications where space and weight constraints are critical, such as transportation.

- Efficiency Improvements:

- Advances in heat engine technology, design, and materials contribute to continuous improvements in efficiency. Research and development efforts focus on enhancing the performance of heat engines to increase their energy conversion efficiency.

- Combined Heat and Power (CHP) Systems:

- Heat engines are often used in combined heat and power systems, where they simultaneously generate electricity and utilize waste heat for heating applications. This co-generation improves overall energy efficiency and resource utilization.

- Reliability and Longevity:

- Many heat engines, such as internal combustion engines and steam turbines, are well-established technologies known for their reliability and longevity. Proper maintenance and engineering practices contribute to their extended operational lifetimes.

- Variety of Designs:

- Heat engines come in various designs, including internal combustion engines, steam engines, gas turbines, and Stirling engines. This diversity allows for the selection of an appropriate design based on specific application requirements and conditions.

- Scalability:

- Heat engines can be scaled to different sizes to match the power requirements of different applications. This scalability makes them suitable for both small-scale applications, such as portable generators, and large-scale power plants.

- Integration with Renewable Energy:

- Heat engines can be integrated with renewable energy sources, such as solar thermal or geothermal energy, to generate power. This integration contributes to a more sustainable and diversified energy portfolio.

While heat engines offer numerous advantages, it’s important to acknowledge that they also face challenges, such as environmental concerns related to emissions and the finite nature of some fuel sources. Ongoing research focuses on addressing these challenges and improving the overall sustainability of heat engine technologies.

Disadvantages of Heat Engine

Despite their advantages, heat engines also come with certain disadvantages. Here are some common drawbacks associated with heat engines:

- Efficiency Limitations:

- No heat engine can be 100% efficient due to the inherent limitations imposed by the second law of thermodynamics. Some energy is always lost as waste heat during the conversion process.

- Environmental Impact:

- Internal combustion engines, which are widely used in transportation, release pollutants such as carbon dioxide (CO2), nitrogen oxides (NOx), and particulate matter. These emissions contribute to air pollution and are associated with climate change.

- Resource Dependence:

- Many heat engines rely on non-renewable fossil fuels as their primary energy source. This dependence poses challenges related to resource depletion, geopolitical issues, and environmental degradation associated with extraction and combustion.

- Heat Rejection:

- Heat engines must reject waste heat to a low-temperature reservoir as part of their thermodynamic cycle. This heat rejection can contribute to environmental concerns, especially if it impacts local ecosystems, water bodies, or urban heat islands.

- Noise and Vibration:

- Some heat engines, particularly internal combustion engines, can generate noise and vibrations during operation. This can lead to noise pollution and discomfort for individuals living or working in close proximity to the engine.

- Maintenance Requirements:

- Heat engines, especially those with moving parts like pistons and turbines, require regular maintenance. Wear and tear can lead to reduced efficiency and the need for periodic overhauls or replacements.

- Limited Fuel Efficiency:

- The thermal efficiency of heat engines can vary based on the type of engine and operating conditions. In certain applications, the efficiency may be lower, especially for smaller engines or those operating at partial loads.

- Complexity and Size:

- Some heat engines, such as steam turbines or gas turbines used in power plants, can be large and complex. The associated infrastructure and space requirements may limit their applicability in certain settings.

- Start-Up Time:

- Certain types of heat engines may have a longer start-up time compared to other power generation technologies. This characteristic may limit their suitability for applications requiring rapid response or intermittent operation.

- Finite Resources:

- The finite availability of fossil fuels poses a long-term challenge for heat engines dependent on these resources. Transitioning to renewable and sustainable energy sources is essential to address concerns related to resource depletion.

Efforts are ongoing to address these disadvantages through advancements in technology, the development of cleaner and more efficient engine designs, and the promotion of sustainable energy practices. Alternative technologies, such as electric vehicles and renewable energy systems, are also emerging as potential solutions to some of these challenges.

Heat Engine Efficiency

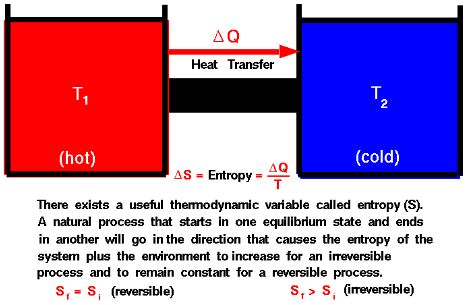

The efficiency of a heat engine is a crucial parameter that measures how effectively the engine converts heat energy into mechanical work. It is defined as the ratio of the useful work output to the heat input. The efficiency of a heat engine is always less than 100% due to the inherent limitations imposed by the second law of thermodynamics.

The efficiency (η) of a heat engine is mathematically expressed as:

η=Useful Work Output/Heat Input

The efficiency can also be expressed in terms of temperatures using the Carnot efficiency (ηCarnot), which represents the maximum possible efficiency for a heat engine operating between two temperature reservoirs (a high-temperature reservoir at Th and a low-temperature reservoir at Tc):

ηCarnot=1−Tc/Th

where Tc is the absolute temperature of the cold reservoir, and Th is the absolute temperature of the hot reservoir.

Key points regarding heat engine efficiency:

- Carnot Efficiency:

- The Carnot efficiency represents the upper limit of efficiency that a heat engine can achieve when operating between two temperature reservoirs. Real-world engines typically operate at lower efficiencies due to irreversibilities and losses.

- Factors Affecting Efficiency:

- Several factors influence the efficiency of a heat engine, including the temperature difference between the heat source and sink, the type of working substance, and the specific thermodynamic cycle used.

- Irreversibilities and Losses:

- Irreversibilities in the thermodynamic processes, such as friction, heat losses, and internal irreversibilities within the engine, contribute to a decrease in efficiency compared to the idealized Carnot efficiency.

- Efficiency Improvements:

- Advances in technology, materials, and design contribute to improving the efficiency of heat engines. Research focuses on minimizing losses and optimizing thermodynamic processes to enhance overall performance.

- Different Types of Engines:

- Different types of heat engines, such as internal combustion engines, steam engines, and gas turbines, have varying efficiencies. Each type of engine has its advantages and trade-offs depending on the application.

- Combined Heat and Power (CHP) Systems:

- Combined heat and power (CHP) systems, also known as cogeneration, can improve overall efficiency by utilizing waste heat for heating applications, in addition to generating electricity.

- Energy Source Impact:

- The choice of energy source, whether it’s fossil fuels, renewable resources, or nuclear power, can impact the overall efficiency and environmental footprint of a heat engine.

- Renewable Energy Integration:

- Integrating heat engines with renewable energy sources, such as solar thermal or geothermal energy, contributes to sustainable power generation with lower environmental impact.

Understanding and improving the efficiency of heat engines is essential for optimizing energy conversion processes, reducing environmental impacts, and addressing global energy challenges. Ongoing research and development efforts aim to enhance the performance of heat engines across various applications.

Types of Heat Engine

There are several types of heat engines, each with its own characteristics, working principles, and applications. Here are some common types of heat engines:

- Internal Combustion Engines:

- Description: Internal combustion engines burn fuel (commonly gasoline or diesel) within the engine itself. They include both spark-ignition engines (e.g., gasoline engines) and compression-ignition engines (e.g., diesel engines).

- Applications: Widely used in automobiles, motorcycles, trucks, and small-scale power generators.

- Steam Engines:

- Description: Steam engines use water as a working substance. Water is heated to produce steam, and the expanding steam is used to perform mechanical work.

- Applications: Historically used in locomotives, ships, and industrial machinery. Although less common today, they are still used in some power plants.

- Gas Turbines (Jet Engines):

- Description: Gas turbines, or jet engines, operate by compressing air, mixing it with fuel, and igniting the mixture. The expanding gases are then used to turn a turbine and produce mechanical work.

- Applications: Aircraft propulsion, power generation, and certain industrial applications.

- Stirling Engines:

- Description: Stirling engines operate on the principle of a fixed quantity of gas undergoing cyclic compression and expansion. The working gas is typically contained within a closed system, and heat is transferred through a regenerator.

- Applications: Limited use in power generation, solar power systems, and some niche applications due to their relatively low efficiency.

- Rankine Cycle Engines:

- Description: The Rankine cycle is a thermodynamic cycle used in steam power plants. It involves the vaporization and condensation of a working fluid, often water.

- Applications: Commonly used in large-scale power plants for electricity generation.

- Brayton Cycle Engines:

- Description: The Brayton cycle is a thermodynamic cycle used in gas turbines. It involves the compression, combustion, and expansion of air.

- Applications: Gas turbine engines for aircraft propulsion, power plants, and industrial processes.

- Combined Heat and Power (CHP) Systems:

- Description: CHP systems, also known as cogeneration, utilize a combination of heat and power generation. They maximize overall efficiency by capturing and using waste heat for heating applications.

- Applications: Various industrial processes, district heating, and commercial buildings.

- External Combustion Engines:

- Description: External combustion engines, such as Stirling engines and steam engines, have the combustion process occurring outside the engine itself.

- Applications: Stirling engines are used in certain power generation applications and as part of solar power systems.

These types of heat engines differ in their working fluids, thermodynamic cycles, and specific applications. The choice of a heat engine depends on factors such as the intended application, efficiency requirements, and available energy sources.

What is Refrigerator?

A refrigerator is a household appliance or a cooling system designed to remove heat from the contents of a space, usually the interior of the refrigerator, and transfer it to the external environment. The primary purpose of a refrigerator is to lower the temperature inside its compartments, preserving food and other perishable items by slowing down bacterial growth and chemical reactions.

Key features and components of a refrigerator include:

- Thermodynamic Cycle:

- Refrigerators operate on a thermodynamic cycle known as the vapor compression cycle. This cycle involves the compression, condensation, expansion, and evaporation of a refrigerant fluid.

- Compressor:

- The compressor is a crucial component that pressurizes the refrigerant gas, raising its temperature and pressure. This compressed gas is then sent to the condenser.

- Condenser:

- In the condenser, the high-pressure, high-temperature refrigerant gas releases heat to the external environment and condenses into a high-pressure liquid.

- Expansion Valve:

- The expansion valve reduces the pressure of the liquid refrigerant, causing it to expand and cool rapidly.

- Evaporator:

- The cooled and expanded refrigerant passes through the evaporator coils located inside the refrigerator. Heat is absorbed from the contents of the refrigerator, causing the refrigerant to evaporate.

- Heat Removal:

- The heat absorbed from the interior of the refrigerator is transferred to the external environment during the condensation phase. This continuous cycle results in the removal of heat from the refrigerated space.

- Temperature Control:

- Refrigerators typically have a thermostat that allows users to set the desired temperature. The thermostat controls the operation of the compressor based on the internal temperature.

- Insulation:

- Refrigerators are well-insulated to minimize heat exchange with the external environment. This insulation helps maintain a lower temperature inside the refrigerator.

- Door Seals:

- To prevent warm air from entering the refrigerator, door seals are used to create an airtight seal when the door is closed.

- Shelves and Compartments:

- Refrigerators are equipped with shelves and compartments to organize and store various types of food and beverages.

Refrigerators come in various sizes, designs, and configurations, including top-freezer, bottom-freezer, side-by-side, and French door models. Advanced features such as ice makers, water dispensers, and smart technology have become common in modern refrigerators.

The ability to cool and preserve food makes refrigerators an essential appliance in households, commercial establishments, and various industries. They contribute to food safety, reduce waste, and enhance convenience in storing and accessing perishable items.

History of Refrigeration

The history of refrigeration dates back to ancient times when people used various methods to cool and preserve food. However, the development of modern refrigeration technology began in the 18th century and has since played a crucial role in various industries, particularly in food preservation, medicine, and comfort cooling. Here is a brief overview of the key milestones in the history of refrigeration:

- Ancient Ice Houses:

- Ancient civilizations, including the Egyptians and Chinese, stored ice and snow in specially designed structures to preserve food and provide relief from heat.

- Evaporation and Cooling Methods:

- In various cultures, people used evaporative cooling methods. For example, the ancient Greeks and Romans soaked cloth in water and draped it over containers to cool the contents as the water evaporated.

- William Cullen’s Demonstration (1748):

- Scottish scientist William Cullen demonstrated the first artificial refrigeration at the University of Glasgow. He used a pump to create a partial vacuum, causing ether to boil and absorb heat.

- Benjamin Franklin’s Experiments (1758):

- Benjamin Franklin, an American scientist, conducted experiments with the evaporation of highly volatile liquids to achieve cooling effects.

- Oliver Evans’ Refrigeration Machine (1805):

- American inventor Oliver Evans designed a refrigeration machine that used vapor-compression. However, it was never built or implemented.

- Jacob Perkins’ Refrigeration Machine (1834):

- American inventor Jacob Perkins received a patent for a vapor-compression refrigeration system. Perkins’ design laid the groundwork for future developments in refrigeration technology.

- John Gorrie’s Ice-Making Machine (1851):

- American physician John Gorrie developed a mechanical ice-making machine, essentially creating the first artificial refrigeration system. His machine was designed to cool hospital rooms and preserve medicines.

- Carl von Linde’s Refrigeration Cycle (1876):

- German engineer Carl von Linde developed a practical and efficient vapor-compression refrigeration system. His innovations significantly advanced the field of refrigeration technology.

- Domestic Refrigerators (Early 20th Century):

- In the early 1900s, companies like Kelvinator and Frigidaire introduced the first mass-produced refrigerators for household use. These early models were often referred to as “iceboxes” and used coolants like sulfur dioxide or methyl formate.

- Freon Refrigerants (1930s):

- The development of synthetic refrigerants, such as Freon (chlorofluorocarbons or CFCs), in the 1930s improved the efficiency and safety of refrigeration systems.

- Modern Refrigeration (20th Century):

- Advances in technology and refrigerants led to the development of modern refrigerators with improved energy efficiency, automated defrosting, and additional features.

- Commercial and Industrial Refrigeration:

- Refrigeration technology became integral to various industries, including food processing, pharmaceuticals, and the cold storage of perishable goods.

- Environmental Concerns and Refrigerant Alternatives (Late 20th Century and Beyond):

- Concerns about ozone depletion and global warming potential led to the phase-out of CFCs and HCFCs. Hydrofluorocarbons (HFCs) were introduced as alternatives, and ongoing efforts focus on developing environmentally friendly refrigerants.

The history of refrigeration reflects a continuous evolution of technology, from ancient cooling methods to sophisticated modern refrigeration systems that are essential for various aspects of daily life and industry. Ongoing research and development continue to drive improvements in energy efficiency and environmental sustainability in refrigeration technology.

Advantages of Refrigerator

In the field of thermodynamics, the operation of a refrigerator is characterized by the principles of heat transfer and energy conservation. Here are the advantages of a refrigerator from a thermodynamics perspective:

- Heat Removal from Contents:

- A refrigerator effectively removes heat from its interior, preserving perishable items by maintaining a lower temperature. This is achieved through the process of absorbing heat from the contents and rejecting it to the external environment.

- Vapor Compression Cycle:

- Refrigerators operate on the vapor compression cycle, a thermodynamic process that involves the compression, condensation, expansion, and evaporation of a refrigerant. This cycle allows for efficient heat transfer and temperature control.

- Temperature Control:

- Refrigerators provide precise temperature control through the regulation of the vapor compression cycle. This enables users to set and maintain specific temperatures to suit the storage requirements of different types of food.

- Preservation of Food:

- The ability to maintain a low and consistent temperature helps preserve food by slowing down bacterial growth and chemical reactions. This preservation is crucial for preventing spoilage and extending the shelf life of perishable items.

- Energy Efficiency:

- Modern refrigerators are designed for energy efficiency, with features such as improved insulation, energy-efficient compressors, and smart temperature control systems. This focus on efficiency aligns with the principles of thermodynamics.

- Heat Exchange with External Environment:

- The refrigeration process involves the absorption of heat from the interior (evaporation) and the rejection of heat to the external environment (condensation). This heat exchange is fundamental to the operation of a refrigerator.

- Adaptability to Different Applications:

- Refrigeration principles are adaptable to various applications beyond household refrigerators. They are used in commercial refrigeration, industrial processes, and other sectors where temperature control and heat removal are essential.

- Prevention of Foodborne Illness:

- By maintaining a low temperature, refrigerators help prevent the growth of harmful bacteria in food, reducing the risk of foodborne illnesses. This is a critical advantage for food safety and public health.

- Convenience and Comfort:

- Refrigerators contribute to the convenience and comfort of daily life by providing a reliable means of preserving food, storing beverages, and keeping perishable items fresh.

- Reduced Dependency on Natural Ice:

- Historically, people depended on natural ice or ice houses for cooling. Refrigerators eliminate the need for these traditional methods and offer a more controlled and efficient means of cooling.

Understanding the thermodynamics of refrigeration allows for the design and optimization of refrigeration systems to achieve efficient heat transfer and temperature control. Advances in refrigeration technology continue to align with thermodynamic principles, leading to improvements in energy efficiency, environmental sustainability, and overall performance.

Disadvantages of Refrigerator

While refrigerators offer numerous advantages in terms of preserving food and providing temperature control, there are also some thermodynamic and practical disadvantages associated with their operation. Here are some considerations:

- Energy Consumption:

- Refrigerators consume electrical energy to operate, and their continuous operation contributes to household energy consumption. This can be a disadvantage from an environmental and economic perspective, especially if the electricity is generated from non-renewable sources.

- Heat Rejection:

- The process of rejecting heat to the external environment during the condensation phase of the vapor compression cycle contributes to heat release in the surroundings. In warmer climates or confined spaces, this can lead to increased ambient temperatures.

- Environmental Impact of Refrigerants:

- The refrigerants used in traditional refrigerators, such as hydrofluorocarbons (HFCs), can have a high global warming potential (GWP) and contribute to climate change. Ongoing efforts focus on developing environmentally friendly refrigerants with lower GWP.

- Complexity and Maintenance:

- Refrigerators are complex systems with various components, including compressors, condensers, evaporators, and thermostats. Maintenance and repairs may require specialized knowledge and can be costly.

- Limited Efficiency at Higher Temperatures:

- The efficiency of refrigerators may decrease in environments with high ambient temperatures. The cooling process becomes less effective as the temperature difference between the interior and exterior increases.

- Noise and Vibration:

- Refrigerators, especially older models, can produce noise and vibrations during operation. This can be a disadvantage in quiet environments or in living spaces where noise may be disruptive.

- Initial Cost and Affordability:

- The initial cost of purchasing a refrigerator can be a significant investment. While modern refrigerators are designed to be energy-efficient, the upfront cost may pose a financial challenge for some consumers.

- Dependence on Electricity:

- Refrigerators are dependent on a reliable electricity supply. Power outages or interruptions can affect their operation, potentially leading to food spoilage and inconvenience.

- Space Limitations:

- The design and size of refrigerators may not always accommodate the storage needs of larger households or specific storage requirements, limiting their practicality in certain situations.

- Waste Generation:

- When refrigerators reach the end of their lifespan, the disposal of old appliances can contribute to electronic waste. Proper recycling and disposal methods are essential to minimize environmental impact.

While refrigerators are indispensable in modern households, it’s important to consider their thermodynamic implications and explore ongoing efforts to improve their efficiency, environmental sustainability, and overall impact. Advances in technology, including the use of alternative refrigerants and energy-efficient designs, aim to address some of these disadvantages.

What is Heat Pump?

A heat pump is a thermodynamic device that transfers heat from one location to another. Unlike traditional heating systems that generate heat, a heat pump moves heat from a lower-temperature source to a higher-temperature sink using a refrigeration cycle. Heat pumps can be used for both heating and cooling applications and are considered energy-efficient systems.

Key components and features of a heat pump include:

- Evaporator:

- The evaporator is the component that absorbs heat from the low-temperature source, such as outdoor air, water, or the ground. The working fluid (refrigerant) evaporates in the evaporator, absorbing heat in the process.

- Compressor:

- The compressor pressurizes the low-pressure, low-temperature vaporized refrigerant from the evaporator, raising its temperature and pressure. This is a key component in the refrigeration cycle that enables efficient heat transfer.

- Condenser:

- The condenser releases heat to the higher-temperature sink (e.g., indoor space). The high-pressure, high-temperature refrigerant vapor in the compressor is condensed in the condenser, transferring heat to the indoor environment.

- Expansion Valve:

- The expansion valve regulates the flow of the refrigerant, reducing its pressure before it enters the evaporator. This expansion causes the refrigerant to evaporate and absorb heat from the low-temperature source, completing the cycle.

- Refrigerant:

- The refrigerant is the working fluid circulating within the heat pump system. It undergoes phase changes (evaporation and condensation) to absorb and release heat during the cycle.

Heat pumps can be categorized based on the source from which they extract heat and the destination to which they deliver it:

- Air Source Heat Pumps (ASHP):

- Extract heat from the outdoor air and transfer it to the indoor space for heating. ASHPs can also be used for cooling by reversing the refrigeration cycle.

- Ground Source Heat Pumps (GSHP):

- Extract heat from the ground through ground loops (buried pipes containing a heat-transfer fluid) and transfer it to the indoor space for heating. GSHPs are known for their high efficiency.

- Water Source Heat Pumps:

- Extract heat from a water source, such as a lake or river, and transfer it for heating or cooling applications.

- Geothermal Heat Pumps:

- A broader term that includes ground source heat pumps, but can also refer to heat pumps that extract heat from geothermal reservoirs deep within the Earth.

- Absorption Heat Pumps:

- Use a heat source, such as natural gas or solar energy, to drive the absorption process, allowing the pump to move heat.

Advantages of Heat Pumps:

- Energy Efficiency: Heat pumps are known for their energy efficiency, as they can deliver more heating or cooling energy than the electrical energy they consume.

- Versatility: Heat pumps can provide both heating and cooling, making them versatile for year-round climate control.

- Reduced Carbon Emissions: Heat pumps, especially those powered by renewable energy sources, contribute to lower carbon emissions compared to traditional heating systems.

- Cost Savings: In regions with moderate climates, heat pumps can be cost-effective in terms of both installation and operation.

Heat pumps are widely used in residential, commercial, and industrial applications for space heating, water heating, and air conditioning. Their efficiency and environmental benefits contribute to their popularity as an alternative to traditional heating and cooling systems.

Disadvantages of Heat Pumps:

While heat pumps offer several advantages, they also have some disadvantages that should be considered. Here are some of the potential drawbacks associated with heat pumps:

- Upfront Cost:

- The initial cost of purchasing and installing a heat pump can be higher compared to traditional heating and cooling systems. This cost includes the purchase of the unit, installation, and any necessary modifications to the existing system.

- Climate Sensitivity:

- The efficiency of air-source heat pumps (ASHP) can be affected by outside air temperatures. In very cold climates, the efficiency may decrease, leading to reduced heating capacity. Supplemental heating systems may be required in extremely cold weather.

- Installation Complexity:

- The installation of certain types of heat pumps, such as ground-source heat pumps (GSHP), can be complex and may require excavation or drilling for the installation of ground loops. This can add to the overall installation cost.

- Space Requirements:

- Ground-source heat pumps, which use ground loops buried in the ground, may require a significant amount of space for installation. This can be a limitation in areas with limited outdoor space.

- Maintenance Requirements:

- Heat pumps require regular maintenance to ensure optimal performance. This includes checking refrigerant levels, cleaning coils, and inspecting components. Failure to perform regular maintenance can lead to reduced efficiency and potential system malfunctions.

- Noise Level:

- Some heat pumps, especially older models, may produce noise during operation. While modern units are designed to be quieter, noise levels can still be a consideration, particularly for air-source heat pumps installed near living spaces.

- Potential for Air Quality Issues:

- Air-source heat pumps may circulate outdoor air into the indoor space during the heating or cooling process. This can potentially introduce outdoor pollutants or allergens into the indoor environment.

- Limited Cooling Efficiency in Some Climates:

- In regions with extremely high temperatures, air-source heat pumps may experience reduced cooling efficiency. This can result in higher electricity consumption and reduced cooling capacity.

- Dependence on Electricity:

- Heat pumps rely on electricity to operate. In regions with unreliable electricity supply or during power outages, the heating or cooling function may be disrupted.

- Refrigerant Considerations:

- The refrigerants used in heat pumps can have environmental impacts. Older models may use refrigerants with higher global warming potential (GWP), contributing to climate change. Newer models often use more environmentally friendly refrigerants, but their long-term environmental impact should be considered.

While these disadvantages are important to note, it’s worth emphasizing that advancements in heat pump technology, increased energy efficiency, and the use of environmentally friendly refrigerants are addressing some of these concerns. Proper sizing, installation, and maintenance by qualified professionals can also help mitigate potential issues associated with heat pumps.

Heat engine: Frequently Asked Questions – FAQ’s

Are there advancements in heat engine technology?

Yes, ongoing research focuses on developing advanced materials, more efficient thermodynamic cycles, and innovative designs. Sustainable technologies, such as combined heat and power (CHP) systems, aim to improve the overall efficiency and reduce environmental impact.

How do heat engines contribute to environmental impact?

The environmental impact of heat engines is often associated with the combustion of fossil fuels, leading to greenhouse gas emissions. Efforts to mitigate environmental impact include developing alternative fuels, improving combustion efficiency, and increasing the use of renewable energy sources.

What are the challenges in designing efficient heat engines?

Challenges include minimizing friction and heat losses, improving combustion efficiency in internal combustion engines, selecting appropriate working fluids, and addressing environmental concerns related to emissions and fuel consumption.

Can heat engines operate in reverse as refrigerators or heat pumps?

Yes, the thermodynamic processes of a heat engine can be reversed to create refrigerators or heat pumps. This is known as the reverse Carnot cycle. Heat is extracted from a low-temperature source and rejected to a high-temperature sink for refrigeration, or vice versa for heat pumps.

What are the applications of heat engines?

Heat engines are used in various applications, including power generation in electricity plants, propulsion systems for vehicles and aircraft, industrial processes, and heating systems. Internal combustion engines power most automobiles, while steam turbines are common in power plants.

How can the efficiency of a heat engine be improved?

Improving the efficiency of a heat engine involves minimizing losses, reducing internal irreversibilities, and optimizing thermodynamic processes. Advances in materials, design, and technology contribute to enhancing overall performance.

What is the efficiency of a heat engine?

The efficiency of a heat engine is the ratio of the useful work output to the heat input. It is always less than 100% due to the second law of thermodynamics. The Carnot efficiency represents the maximum possible efficiency for a heat engine operating between two temperature reservoirs.

What are the types of heat engines?

Heat engines can be classified into external combustion engines (e.g., steam engines) and internal combustion engines (e.g., gasoline and diesel engines). They can also be categorized based on the working fluid and specific thermodynamic cycles they employ.

How does a heat engine work?

A heat engine typically operates on a thermodynamic cycle, such as the Carnot cycle or Rankine cycle. It involves four main processes: compression, heat addition, expansion, and heat rejection. These processes are driven by changes in temperature and pressure of a working fluid.

What is a heat engine?

A heat engine is a device that converts thermal energy (heat) into mechanical work. It operates based on the principles of thermodynamics, specifically by extracting heat from a high-temperature source, performing work, and rejecting waste heat to a lower-temperature sink.

Refrigerator: Frequently Asked Questions – FAQ’s

What should I do if my refrigerator is not cooling properly?

Check for common issues such as blocked vents, dirty coils, or improper temperature settings. If the problem persists, it may require professional inspection to identify and address issues with the compressor, thermostat, or other components.

How long does a refrigerator typically last?

The lifespan of a refrigerator varies, but on average, it can last between 10 to 20 years. Regular maintenance, such as cleaning coils and checking door seals, can contribute to its longevity.

What is the purpose of the crisper drawer in the refrigerator?

The crisper drawer is designed to maintain higher humidity levels, keeping fruits and vegetables fresh for a longer time. It helps prevent moisture loss and preserves the crispness of produce.

How can I improve the energy efficiency of my refrigerator?

To improve energy efficiency, ensure the refrigerator door seals are intact, set the temperature to the recommended level, avoid overloading the refrigerator, and keep the coils clean. Regular maintenance can also contribute to optimal efficiency.

Can I store hot food directly in the refrigerator?

It’s advisable to let hot food cool to room temperature before placing it in the refrigerator. Putting hot food directly into the refrigerator can raise the internal temperature and affect the cooling efficiency.

Why does the refrigerator make noise?

Some noise is normal, such as the sound of the compressor, fans, or ice maker. Excessive or unusual noise may indicate an issue with the refrigerator, such as a faulty fan motor or compressor, and may require professional attention.

How often should I clean the coils on the back of the refrigerator?

It is recommended to clean the coils on the back of the refrigerator at least once or twice a year. Dust and debris on the coils can reduce the efficiency of the refrigerator by hindering heat exchange.

Why is there water droplets on the interior of the refrigerator?

Water droplets on the interior of the refrigerator are usually the result of condensation. When warm air enters the refrigerator and comes into contact with the cold surfaces, moisture in the air condenses into water droplets.

What is the ideal temperature for a refrigerator?

The recommended temperature for a refrigerator is around 37 to 40 degrees Fahrenheit (3 to 4 degrees Celsius). This temperature range helps preserve food by slowing down bacterial growth and maintaining freshness.

How does a refrigerator work

A refrigerator works on the principle of a vapor compression cycle. It uses a refrigerant to absorb heat from the interior of the refrigerator, compresses the refrigerant to release the absorbed heat outside, and then allows the refrigerant to expand and absorb more heat.

Heat Pump: Frequently Asked Questions – FAQ’s

Can a heat pump be used in conjunction with other heating systems?

Yes, heat pumps can be used in conjunction with other heating systems, such as electric resistance heaters or gas furnaces, in a setup known as a dual-fuel or hybrid system. This allows for efficient heating in extremely cold temperatures.

What maintenance is required for a heat pump?

Regular maintenance includes cleaning or replacing air filters, checking and cleaning coils, inspecting refrigerant levels, and ensuring proper airflow. Professional maintenance is recommended at least once a year.

Are heat pumps environmentally friendly?

Heat pumps can be environmentally friendly, especially if they are powered by renewable energy sources. However, the environmental impact depends on the electricity source. Heat pumps that use refrigerants with lower global warming potential are also considered more environmentally friendly.

Can a heat pump operate in cold climates?

Yes, modern heat pumps are designed to operate efficiently in cold climates. However, in extremely cold temperatures, the efficiency may decrease, and supplemental heating may be needed.

How does a heat pump differ from a traditional furnace or air conditioner?

Unlike traditional heating and cooling systems that generate heat or cool air, a heat pump moves heat from one location to another. It operates on the principles of heat transfer and can be more energy-efficient, especially in moderate climates.

Can a heat pump be used for cooling?

Yes, a heat pump can be used for both heating and cooling. In the heating mode, it extracts heat from the outside air, ground, or water and transfers it indoors. In the cooling mode, it reverses the process, extracting heat from the indoor space and releasing it outside.

How energy-efficient are heat pumps?

Heat pumps can be highly energy-efficient, especially in moderate climates. They move heat rather than generate it, making them more efficient for space heating. The efficiency is often measured by the Coefficient of Performance (COP), which compares the energy input to the heat output.

What are the types of heat pumps?

There are several types of heat pumps, including air-source heat pumps (ASHP), ground-source heat pumps (GSHP or geothermal heat pumps), and water-source heat pumps. They differ based on the heat source they utilize.

What is the difference between an air-source and a ground-source heat pump?

An air-source heat pump extracts heat from the outdoor air, while a ground-source heat pump extracts heat from the ground. Ground-source heat pumps are often more efficient but may have higher installation costs.

What is a heat pump?

A heat pump is a thermodynamic device that transfers heat from a low-temperature source to a higher-temperature sink. It can provide both heating and cooling by reversing the direction of the heat transfer process.