What is Junker’s Gas Calorimeter?

Junker’s gas calorimeter is a device designed for the measurement of the calorific value of gaseous fuels, particularly natural gas. It is named after the German engineer Otto Junker, who developed this calorimeter. The calorific value, also known as heating value or energy content, represents the amount of heat released per unit volume or mass of a fuel during combustion.

Here are the key components and features of Junker’s gas calorimeter:

- Combustion Chamber:

- The device consists of a combustion chamber where the gaseous fuel is burned in the presence of excess air or oxygen. The combustion process is controlled to ensure complete and efficient burning of the gas.

- Water Jacket:

- A water jacket surrounds the combustion chamber. The heat generated during the combustion of the gas is transferred to the water, causing its temperature to rise.

- Heat Exchanger:

- A heat exchanger is used to transfer the heat from the water to a circulating cooling water system. This helps in maintaining a constant temperature in the calorimeter and facilitates accurate heat transfer measurements.

- Temperature Measurement:

- Thermometers or temperature sensors are used to measure the temperature rise of the water caused by the heat released during combustion. This temperature change is essential for calculating the calorific value of the gas.

- Flow Measurement:

- The flow rate of the gaseous fuel is carefully controlled and measured during the combustion process. This information is necessary for accurately determining the calorific value.

- Calibration:

- Junker’s gas calorimeter requires calibration using a standard reference gas with a known calorific value. This calibration step ensures the accuracy and reliability of the calorimeter measurements.

- Pressure Regulation:

- The pressure of the gas is regulated to ensure consistent and controlled conditions during combustion. This is crucial for accurate calorific value calculations.

- Data Recording and Analysis:

- The calorimeter is equipped with instruments for recording temperature, pressure, and flow rate data. These data are then used to calculate the calorific value of the gas.

Junker’s gas calorimeter is widely used in laboratories and industries for routine analysis of the calorific values of gaseous fuels. It is an important tool for quality control in the natural gas industry, where precise knowledge of the energy content of the gas is essential for various applications, including power generation and heating. The calorimeter provides valuable information for optimizing combustion processes and ensuring the efficient use of gaseous fuels.

Formula of Junker’s Gas Calorimeter

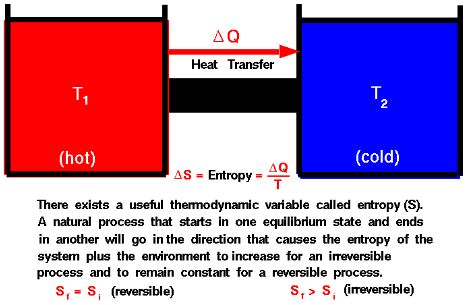

Junker’s gas calorimeter is primarily used to measure the calorific value of gaseous fuels. The calorific value (CV) is typically expressed in terms of energy released per unit volume or mass of the fuel during combustion. The formula for calculating the calorific value in a Junker’s gas calorimeter involves measuring the temperature rise of water and other relevant parameters.

The general formula for calorific value (CV) determination in a calorimeter is given by:

CV=mQ

Where:

- CV is the calorific value (energy released per unit mass or volume),

- Q is the heat released during combustion,

- m is the mass or volume of the fuel burned.

In Junker’s gas calorimeter, the heat released (Q) during the combustion of the gaseous fuel is absorbed by the water in the water jacket, causing a temperature rise. The heat transfer (Q) is related to the temperature rise (ΔT), mass of water (m), and the specific heat capacity of water (c) using the formula:

Q=m⋅c⋅ΔT

Where:

- Q is the heat transfer,

- m is the mass of water,

- c is the specific heat capacity of water,

- ΔT is the temperature rise.

By substituting the expression for Q into the initial formula, the calorific value (CV) can be determined:

CV=m⋅c⋅ΔT/m

The mass of water (m) cancels out, leaving:

CV=c⋅ΔT

This simplified formula shows that the calorific value is directly proportional to the temperature rise of the water in the calorimeter and the specific heat capacity of water.

It’s important to note that the actual calorific value calculation may involve additional corrections and factors to account for various parameters and ensure accurate measurements. Calibration with a standard reference gas of known calorific value is also an essential step in the accurate determination of the calorific value using Junker’s gas calorimeter.

Construction of Junker’s Gas Calorimeter

The construction of Junker’s gas calorimeter involves several key components to facilitate the measurement of the calorific value of gaseous fuels. While specific designs may vary, here is a general overview of the construction:

- Combustion Chamber:

- The calorimeter includes a combustion chamber where the gaseous fuel is burned. This chamber is designed to ensure complete combustion of the gas.

- Water Jacket:

- A water jacket surrounds the combustion chamber. This jacket is filled with water and serves to absorb the heat generated during the combustion process. The temperature rise of the water is a crucial parameter for calculating the calorific value.

- Heat Exchanger:

- A heat exchanger is employed to transfer the heat from the water jacket to a circulating cooling water system. This helps maintain a constant temperature within the calorimeter and enables accurate heat transfer measurements.

- Pressure Control System:

- The calorimeter is equipped with a pressure control system to regulate the pressure of the gaseous fuel during combustion. This is essential for maintaining controlled conditions and ensuring accurate measurements.

- Flow Control System:

- A flow control system is incorporated to regulate and measure the flow rate of the gaseous fuel. Controlling the flow rate is crucial for accurate calorific value calculations.

- Ignition System:

- An ignition system, typically an electrically heated wire or similar mechanism, is used to initiate the combustion of the gaseous fuel within the combustion chamber.

- Temperature Measurement Devices:

- Thermometers or temperature sensors are installed to measure the temperature rise of the water in the jacket. Accurate temperature measurements are necessary for calculating the heat transfer during combustion.

- Calibration Mechanism:

- Junker’s gas calorimeter requires calibration using a standard reference gas with a known calorific value. This calibration mechanism ensures the accuracy and reliability of the calorimeter readings.

- Data Recording Instruments:

- The calorimeter is equipped with instruments to record temperature, pressure, and flow rate data. These instruments may include pressure gauges, thermometers, and flow meters.

- Safety Features:

- Safety features such as pressure relief valves and mechanisms to prevent gas leaks are incorporated to ensure the safe operation of the calorimeter, especially when working with combustible gases.

It’s important to note that the specific design and construction details of Junker’s gas calorimeter may vary among different manufacturers and models. However, the fundamental components outlined above are common features in the construction of gas calorimeters used for measuring the calorific value of gaseous fuels.

Uses of Junker’s Gas Calorimeter

Junker’s gas calorimeter is specifically designed for measuring the calorific value of gaseous fuels. The information obtained from these measurements is valuable in various applications related to the quality and efficiency of gaseous fuels. Here are some key uses of Junker’s gas calorimeter:

- Natural Gas Quality Assessment:

- Junker’s gas calorimeter is commonly used in the natural gas industry to assess the calorific value of natural gas. This information is crucial for ensuring that the delivered natural gas meets specified quality standards.

- Fuel Efficiency in Industrial Processes:

- Industries utilizing gaseous fuels for heating or power generation use Junker’s gas calorimeter to determine the energy content of the fuel. This information helps optimize combustion processes for improved fuel efficiency.

- Quality Control in Gas Production:

- Gas manufacturers use Junker’s gas calorimeter for quality control purposes. By regularly measuring the calorific value of produced gases, manufacturers can ensure consistency and adherence to standards.

- Research and Development:

- Researchers in the field of gas combustion and thermodynamics use Junker’s gas calorimeter to study the characteristics of different gaseous fuels. This contributes to the development of more efficient combustion technologies and alternative fuels.

- Energy Management in Power Plants:

- Power plants using gaseous fuels employ Junker’s gas calorimeter to assess the energy content of the fuel. This data is essential for managing energy production and optimizing power plant efficiency.

- Calibration of Gas Analyzers:

- Junker’s gas calorimeter is used in the calibration of gas analyzers and sensors. Calibrating these instruments with a known calorific value reference gas ensures the accuracy of gas composition measurements.

- Environmental Monitoring:

- In environmental studies, the calorific value of gases can be an indicator of the potential energy recovery from waste gases. Junker’s gas calorimeter is used to assess the energy content of gases emitted from industrial processes or waste treatment facilities.

- Educational Purposes:

- Junker’s gas calorimeter is utilized in educational settings, such as laboratories and technical training institutes, to teach students about calorimetry, combustion reactions, and the energy content of gaseous fuels.

- Evaluating Alternative Fuels:

- As interest in alternative and renewable fuels grows, Junker’s gas calorimeter is employed to evaluate the calorific values of these fuels. This information aids in comparing alternative fuels with traditional gaseous fuels.

- Efficiency Monitoring in Gas Appliances:

- Manufacturers of gas appliances, such as heaters and boilers, may use Junker’s gas calorimeter to assess the efficiency of these appliances under different operating conditions.

The use of Junker’s gas calorimeter contributes to the understanding of gaseous fuel properties, ensuring their efficient and safe utilization in various industrial, research, and energy production applications.

How Junker’s Gas Calorimeter is Manufactured

The manufacturing process of Junker’s gas calorimeter involves several steps to ensure precision, reliability, and adherence to standards. While specific details may vary among manufacturers, here is a general overview of the manufacturing process:

- Design and Engineering:

- The process begins with the design and engineering of the calorimeter. Engineers develop detailed plans, specifications, and schematics based on the principles of Junker’s gas calorimeter.

- Material Selection:

- High-quality materials are selected for the construction of the calorimeter. Materials must be resistant to corrosion, heat, and pressure to ensure the durability and safety of the device.

- Fabrication of Combustion Chamber:

- The combustion chamber is a critical component. It is fabricated with precision machining techniques to ensure proper sealing, uniform heat distribution, and resistance to high temperatures.

- Water Jacket Manufacturing:

- The water jacket that surrounds the combustion chamber is manufactured with materials that have good thermal conductivity. Its design ensures efficient heat transfer from the combustion chamber to the water.

- Pressure Control System:

- The pressure control system, which regulates the pressure of the gaseous fuel during combustion, is designed and integrated into the calorimeter. This system includes valves, regulators, and safety mechanisms.

- Flow Control System:

- The flow control system, responsible for regulating and measuring the flow rate of the gaseous fuel, is carefully manufactured. Flow meters and control valves are calibrated for accuracy.

- Ignition System:

- The ignition system, typically an electrically heated wire, is manufactured to provide a reliable and controlled ignition source for the gaseous fuel.

- Temperature Measurement Devices:

- Temperature measurement devices, such as thermometers or temperature sensors, are integrated into the calorimeter. These devices must provide accurate and precise temperature readings.

- Calibration Mechanism:

- The calibration mechanism, used for calibrating the calorimeter with a standard reference gas of known calorific value, is carefully designed and implemented. This ensures the accuracy of measurements.

- Data Recording Instruments:

- Instruments for recording temperature, pressure, and flow rate data are incorporated into the calorimeter. These instruments may include pressure gauges, thermometers, and flow meters.

- Safety Features:

- Safety features, such as pressure relief valves and mechanisms to prevent gas leaks, are integrated to ensure the safe operation of the calorimeter.

- Quality Control:

- Throughout the manufacturing process, rigorous quality control measures are implemented. This includes inspections, testing, and calibration to ensure that each component meets specifications and standards.

- Assembly:

- The individual components are assembled according to the design specifications. Care is taken to ensure proper alignment, sealing, and integration of all components.

- Testing and Calibration:

- The assembled calorimeter undergoes testing and calibration using known reference gases. This step is crucial to verify the accuracy and reliability of the calorimeter before it is released for use.

- Documentation and Packaging:

- The completed calorimeter is documented, and user manuals are prepared. The device is carefully packaged to protect it during transportation and to ensure its integrity upon arrival at the end-user’s location.

Manufacturers follow stringent quality control processes and adhere to relevant standards during each step of the manufacturing process to produce Junker’s gas calorimeters that meet performance, safety, and accuracy requirements.

Working of Junker’s Gas Calorimeter

Junker’s gas calorimeter is designed to measure the calorific value of gaseous fuels, providing information about the energy content of the gas. The working principle involves the combustion of a known quantity of gas in a controlled environment and the measurement of the heat released during this process. Here is an overview of the working of Junker’s gas calorimeter:

- Setup:

- The calorimeter consists of a combustion chamber, a water jacket, a pressure control system, a flow control system, an ignition system, and temperature measurement devices.

- Calibration:

- Before use, the calorimeter is calibrated using a standard reference gas with a known calorific value. This calibration ensures the accuracy of the calorimeter’s measurements.

- Gas Flow Control:

- The gaseous fuel, typically natural gas, is introduced into the calorimeter at a controlled flow rate. The flow control system ensures a consistent and measured flow of gas.

- Ignition:

- An ignition source, often an electrically heated wire, is used to initiate the combustion of the gaseous fuel within the combustion chamber. The combustion process is carefully controlled to ensure complete burning of the gas.

- Combustion:

- The gaseous fuel combusts in the presence of excess air or oxygen within the combustion chamber. This combustion process releases heat energy.

- Heat Transfer to Water:

- The heat generated during combustion is absorbed by the water jacket surrounding the combustion chamber. The water absorbs the heat, causing its temperature to rise.

- Temperature Measurement:

- Temperature measurement devices, such as thermometers or temperature sensors, are used to measure the temperature rise of the water. This temperature rise is directly proportional to the heat released during combustion.

- Calculation of Calorific Value:

- The calorific value is calculated using the formula CV=c⋅ΔT, where CV is the calorific value, c is the specific heat capacity of water, and ΔT is the temperature rise of the water.

- Pressure Control:

- The pressure of the gaseous fuel during combustion is carefully controlled to ensure consistent conditions and accurate measurements.

- Data Recording:

- Instruments record data related to temperature, pressure, and flow rate. These recorded values are used in the calculation of the calorific value.

- Safety Measures:

- The calorimeter is equipped with safety features, such as pressure relief valves, to ensure the safe operation of the device, especially when dealing with combustible gases.

- Data Analysis and Reporting:

- The recorded data is analyzed, and the calorific value of the gaseous fuel is determined. The results are then reported for various applications, including quality control, research, and process optimization.

Junker’s gas calorimeter provides accurate measurements of the calorific value of gaseous fuels, making it a valuable tool in industries, research laboratories, and educational institutions where the energy content of gases needs to be precisely determined.

Advantages of Junker’s Gas Calorimeter

Junker’s gas calorimeter offers several advantages, making it a widely used instrument for measuring the calorific value of gaseous fuels. Here are some of the key advantages:

- Precision and Accuracy:

- Junker’s gas calorimeter is known for its high precision and accuracy in measuring the calorific value of gaseous fuels. This makes it a reliable tool for quality control and research purposes.

- Wide Applicability:

- The calorimeter can be used for a variety of gaseous fuels, including natural gas. Its versatility allows it to accommodate different types of gases used in various industrial processes.

- Controlled Combustion Process:

- The combustion process in Junker’s calorimeter is carefully controlled to ensure complete burning of the gaseous fuel. This controlled environment contributes to accurate measurements.

- Real-time Data Recording:

- The calorimeter is equipped with instruments for real-time recording of temperature, pressure, and flow rate data. This feature enables efficient data analysis and reporting.

- Safety Measures:

- Safety features, such as pressure relief valves and mechanisms to prevent gas leaks, are integrated into the design of Junker’s gas calorimeter. This ensures safe operation, especially when working with combustible gases.

- Calibration Capabilities:

- The calorimeter can be calibrated using a standard reference gas with a known calorific value. This calibration step enhances the accuracy of the calorimeter’s measurements.

- Efficient Heat Transfer:

- The design of the water jacket and heat exchanger facilitates efficient heat transfer from the combustion chamber to the water. This efficiency is crucial for precise temperature rise measurements.

- Repeatable and Reproducible Results:

- The robust design and controlled conditions in Junker’s calorimeter contribute to the repeatability and reproducibility of results. This is essential for reliable data in quality control and research applications.

- Suitable for Laboratory and Industrial Use:

- The calorimeter is suitable for both laboratory and industrial settings. Its design and features cater to the needs of researchers, quality control laboratories, and industries utilizing gaseous fuels.

- Educational Use:

- Junker’s gas calorimeter is often used in educational institutions for teaching purposes. It provides students with hands-on experience in calorimetry and combustion processes.

- Optimization of Combustion Processes:

- Industries can use the calorific value data obtained from Junker’s gas calorimeter to optimize combustion processes, improving energy efficiency and reducing environmental impact.

- Non-Destructive Testing:

- The measurement process in Junker’s calorimeter is non-destructive, allowing for multiple measurements on the same sample without altering the substance being tested.

- Adaptability to Research Needs:

- Researchers can use Junker’s gas calorimeter to study the combustion characteristics of different gaseous fuels, contributing to advancements in combustion science and technology.

These advantages collectively make Junker’s gas calorimeter a valuable instrument for industries, research laboratories, and educational institutions involved in the analysis and optimization of gaseous fuels.

Disadvantages of Junker’s Gas Calorimeter

While Junker’s gas calorimeter offers several advantages, it also has some limitations and disadvantages. Here are some of the potential drawbacks associated with this type of calorimeter:

- Limited to Gaseous Fuels:

- Junker’s gas calorimeter is specifically designed for measuring the calorific value of gaseous fuels. It is not suitable for analyzing solid or liquid fuels, limiting its applicability in certain contexts.

- Complex Operation:

- The operation of Junker’s gas calorimeter can be complex, requiring careful control of combustion conditions, flow rates, and other parameters. Skilled personnel are often needed for accurate and reliable measurements.

- Sensitivity to Impurities:

- Impurities in the gaseous fuel can affect the accuracy of measurements. Contaminants or variations in gas composition may introduce errors in calorific value calculations.

- Maintenance Requirements:

- Regular maintenance is necessary to ensure the proper functioning of Junker’s gas calorimeter. Components such as valves, regulators, and ignition systems may require periodic checks and adjustments.

- Calibration Challenges:

- Calibrating the calorimeter with a standard reference gas is essential for accurate measurements. However, achieving precise calibration can be challenging and may introduce uncertainties in the results.

- Safety Concerns:

- Handling combustible gases poses inherent safety risks. While safety features are integrated into the calorimeter, there is always a need for strict adherence to safety protocols to prevent accidents.

- Moisture Sensitivity:

- Moisture in the gaseous fuel or ambient air can affect the combustion process and lead to inaccurate results. Special precautions may be required to minimize the impact of moisture.

- Pressure Fluctuations:

- Fluctuations in gas pressure can influence the combustion process and affect the accuracy of calorific value measurements. Maintaining consistent pressure conditions is essential for reliable results.

- Specificity to Certain Gas Types:

- While the calorimeter can accommodate various gaseous fuels, its design may be more optimized for certain types of gases. This specificity may limit its performance for certain gas compositions.

- Cost:

- The initial cost of acquiring and setting up a Junker’s gas calorimeter can be relatively high. This cost may be a factor for smaller laboratories or educational institutions with budget constraints.

- Time-Consuming:

- The process of measuring calorific values using Junker’s gas calorimeter can be time-consuming, particularly when conducting multiple tests or calibrations.

- Environmental Impact:

- Combustion processes contribute to the release of greenhouse gases and other pollutants. While the calorimeter itself is not a significant source, its use involves the combustion of gas, which has environmental implications.

Despite these disadvantages, Junker’s gas calorimeter remains a valuable tool in applications where the calorific value of gaseous fuels needs to be accurately determined. Careful consideration of its limitations and proper handling can help mitigate potential issues.

Frequently Asked Questions – FAQ’s

Are there any limitations to Junker’s gas calorimeter?

Yes, limitations include its specificity to gaseous fuels, complexity in operation, sensitivity to impurities, and the need for regular maintenance. Understanding and addressing these limitations are crucial for obtaining reliable results.

What are the advantages of Junker’s gas calorimeter?

Advantages include high precision, wide applicability to various gaseous fuels, controlled combustion processes, real-time data recording, and suitability for both laboratory and industrial use.

How does moisture affect the measurements in Junker’s gas calorimeter?

Moisture in the gaseous fuel or ambient air can impact combustion and introduce inaccuracies in measurements. Special precautions may be needed to minimize the influence of moisture.

Can Junker’s gas calorimeter be used for educational purposes?

Yes, Junker’s gas calorimeter is often used in educational settings to teach students about calorimetry, combustion reactions, and the energy content of gaseous fuels.

What safety precautions should be taken when using Junker’s gas calorimeter?

Safety precautions include handling combustible gases with care, following proper ignition procedures, and ensuring that safety features like pressure relief valves are in place. Adherence to laboratory safety protocols is essential.

Why is calibration important for Junker’s gas calorimeter?

Calibration with a standard reference gas of known calorific value is crucial to ensure the accuracy of the calorimeter’s measurements. It establishes a reliable basis for calculating the calorific value of the gas being tested.

Is Junker’s gas calorimeter suitable for liquid or solid fuels?

No, Junker’s gas calorimeter is specifically designed for gaseous fuels. It is not suitable for the analysis of liquid or solid fuels.

What types of gases can be analyzed with Junker’s gas calorimeter?

Junker’s gas calorimeter can analyze a variety of gaseous fuels, including natural gas and other industrial gases. Its design allows for versatility in measuring the calorific value of different gas compositions.

How does Junker’s gas calorimeter work?

The calorimeter works by burning a known quantity of gaseous fuel in a controlled environment. The heat released during combustion is absorbed by water, and the resulting temperature rise is used to calculate the calorific value.

What is Junker’s gas calorimeter used for?

Junker’s gas calorimeter is used to measure the calorific value of gaseous fuels. It provides information about the energy content of the gas, which is crucial for various industrial, research, and quality control applications.