What is Refrigerants?

Refrigerants are substances used in refrigeration systems and air conditioning systems to transfer heat from one area to another. These substances undergo a continuous cycle of evaporation and condensation within a closed system, allowing them to absorb heat from the surroundings (such as the interior of a refrigerator or a room) and release it elsewhere (outside the refrigerator or building).

The main purpose of refrigerants is to facilitate the cooling or freezing of a space or substance by removing heat. During the refrigeration cycle, the refrigerant undergoes phase changes from a low-pressure gas to a high-pressure liquid and back again. This cycle involves the absorption of heat when the refrigerant evaporates (turns into a gas) and the release of heat when it condenses (turns back into a liquid).

Common refrigerants have included chlorofluorocarbons (CFCs), hydrochlorofluorocarbons (HCFCs), and hydrofluorocarbons (HFCs). However, due to their environmental impact, particularly their contribution to ozone depletion and global warming, there has been a push to develop and use more environmentally friendly refrigerants, such as hydrofluoroolefins (HFOs) and other low-global-warming-potential alternatives. The transition to environmentally friendly refrigerants is part of global efforts to reduce the impact of human activities on the environment.

Properties of an Ideal Refrigerant?

An ideal refrigerant should possess a combination of properties that make it efficient, safe, and environmentally friendly. Some of the desirable properties of an ideal refrigerant include:

- High Thermal Conductivity: The refrigerant should have high thermal conductivity to facilitate efficient heat transfer during the refrigeration cycle.

- Low Viscosity: A low viscosity ensures that the refrigerant flows easily through the system, reducing energy consumption and making the system more efficient.

- Low Freezing Point: A low freezing point is desirable to prevent the refrigerant from solidifying at low temperatures, which could disrupt the operation of the refrigeration system.

- Chemical Stability: The refrigerant should be chemically stable under normal operating conditions to avoid breakdown or degradation, ensuring a longer lifespan for the system.

- Non-Corrosive: An ideal refrigerant should not corrode or damage the components of the refrigeration system, enhancing the durability of the equipment.

- Non-Toxic and Non-Flammable: Safety is a critical factor, so the refrigerant should be non-toxic and non-flammable to protect both the environment and human health.

- Wide Operating Range: The refrigerant should be effective across a range of temperatures and pressures, allowing for versatile applications in various cooling and heating systems.

- Low Global Warming Potential (GWP): In response to environmental concerns, modern refrigerants should have a low GWP to minimize their contribution to climate change.

- Zero Ozone Depletion Potential (ODP): To protect the ozone layer, the refrigerant should have zero or very low ODP, as substances with high ODP can lead to ozone layer depletion.

- Affordability: The cost of the refrigerant should be reasonable to make the technology economically viable and accessible.

- Ease of Recycling: An ideal refrigerant should be easy to recycle, reducing the environmental impact of its production, use, and disposal.

As environmental awareness increases, there is a growing emphasis on developing and adopting refrigerants that balance these desirable properties while minimizing negative impacts on the environment and human health.

Classification of Refrigerants?

Refrigerants are classified based on their chemical composition and properties. Historically, refrigerants have gone through different classifications as newer compounds are developed in response to environmental concerns. The two main classification systems are based on the type of refrigerants: the traditional classification and the newer, more environmentally friendly classification.

- Traditional Classification:

- CFCs (Chlorofluorocarbons): These include refrigerants with chlorine, fluorine, and carbon atoms in their chemical structure. Common examples include CFC-12 (dichlorodifluoromethane) and CFC-11. CFCs were widely used but are now largely phased out due to their ozone-depleting properties.

- HCFCs (Hydrochlorofluorocarbons): These refrigerants contain hydrogen, chlorine, fluorine, and carbon. Examples include HCFC-22 (chlorodifluoromethane) and HCFC-123. HCFCs have lower ozone-depleting potential than CFCs but still contribute to ozone depletion.

- HFCs (Hydrofluorocarbons): These refrigerants contain hydrogen, fluorine, and carbon but lack chlorine, making them ozone-friendly. Common HFCs include HFC-134a and HFC-410A. While they don’t contribute to ozone depletion, many HFCs have a high global warming potential (GWP), leading to concerns about their environmental impact.

- Newer Classification (Low-GWP Refrigerants):

- HFOs (Hydrofluoroolefins): Developed as a more environmentally friendly alternative to HFCs, HFOs have lower GWPs. For example, HFO-1234yf is used in automotive air conditioning systems.

- Natural Refrigerants: These include substances that occur naturally and have low or zero GWP. Common natural refrigerants are:

- Ammonia (R717): An efficient and widely used refrigerant with zero GWP, but it is toxic and flammable.

- Carbon Dioxide (CO2 or R744): An environmentally friendly option with zero ODP and low GWP, often used in commercial refrigeration systems.

- Hydrocarbons (HCs): Propane (R290) and isobutane (R600a) are examples. They have low GWP but are flammable, so safety precautions are necessary.

- Blends: Some refrigerants are blends of different substances to achieve specific performance characteristics. For example, R410A is a blend of HFCs commonly used in air conditioning systems.

As environmental regulations evolve, there is a shift towards phasing out high-GWP refrigerants and promoting the use of low-GWP and natural refrigerants to mitigate climate change and protect the ozone layer.

Types of Refrigerants?

Refrigerants come in various types, each with its own set of properties and applications.

Here are the main types of refrigerants:

- Chlorofluorocarbons (CFCs):

- Examples: CFC-12 (dichlorodifluoromethane).

- Historical refrigerants that have been largely phased out due to their significant ozone depletion potential.

- Hydrochlorofluorocarbons (HCFCs):

- Examples: HCFC-22 (chlorodifluoromethane).

- Used as transitional alternatives to CFCs, but they still contribute to ozone depletion.

- Hydrofluorocarbons (HFCs):

- Examples: HFC-134a, HFC-410A.

- Commonly used as replacements for CFCs and HCFCs. They have zero ozone depletion potential but high global warming potential.

- Hydrofluoroolefins (HFOs):

- Examples: HFO-1234yf, HFO-1234ze.

- Developed as low-GWP alternatives to HFCs, with improved environmental performance.

- Ammonia (R717):

- Ammonia is a natural refrigerant with zero ozone depletion potential and low global warming potential. It is widely used in industrial refrigeration.

- Carbon Dioxide (CO2 or R744):

- CO2 is a natural refrigerant with zero ozone depletion potential and low global warming potential. It is used in commercial refrigeration and automotive air conditioning systems.

- Hydrocarbons (HCs):

- Examples: Propane (R290), isobutane (R600a).

- Hydrocarbons are natural refrigerants with low global warming potential. They are used in domestic refrigeration and some commercial applications.

- Water (R718):

- Water is a natural refrigerant with zero ozone depletion potential and low global warming potential. It is used in certain applications where its properties are suitable.

- Azeotropic and Zeotropic Blends:

- Blends of different refrigerants are formulated to achieve specific performance characteristics. For example, R410A is a zeotropic blend used in air conditioning systems.

- Inorganic Compounds:

- Examples: Sulfur dioxide (SO2), hydrogen (H2).

- These have limited use due to safety and environmental concerns.

- Secondary Refrigerants:

- Fluids that transfer heat indirectly between the primary refrigerant and the space or substance to be cooled. Examples include water-glycol mixtures, brines, and thermal oils.

The choice of refrigerant depends on factors such as the application, efficiency, safety, environmental impact, and regulatory compliance. In recent years, there has been a significant focus on developing and adopting environmentally friendly refrigerants with lower global warming potential and zero ozone depletion potential.

Advantages of Refrigerants?

Refrigerants play a crucial role in various cooling and air conditioning systems, offering several advantages. Here are some key advantages of refrigerants:

- Efficient Heat Transfer:

- Refrigerants have excellent heat transfer properties, allowing them to efficiently absorb heat from one location (e.g., inside a refrigerator or a building) and release it elsewhere (e.g., outside).

- Phase Change Properties:

- Refrigerants undergo phase changes from liquid to gas and back, which enables them to absorb heat during evaporation and release heat during condensation. This phase change contributes to the effectiveness of the refrigeration cycle.

- Temperature Control:

- Refrigerants allow precise temperature control, making them suitable for various applications, including food storage, air conditioning, and industrial processes.

- Versatility:

- Refrigerants can be used in a wide range of applications, from small domestic refrigerators to large industrial cooling systems. They are versatile and adaptable to different cooling requirements.

- Compact Systems:

- Refrigeration systems using refrigerants can be designed to be relatively compact, making them suitable for a variety of settings where space is limited.

- Ease of Compression and Expansion:

- Refrigerants can be compressed into a high-pressure gas and then expanded into a low-pressure liquid easily. This property facilitates the mechanical work involved in the refrigeration cycle.

- Compatibility with Materials:

- Refrigerants are generally compatible with the materials used in the construction of refrigeration systems, reducing the risk of corrosion or damage to components.

- Chemical Stability:

- Many refrigerants exhibit chemical stability under normal operating conditions, contributing to the reliability and longevity of refrigeration systems.

- Non-Flammability (for some types):

- Certain refrigerants, such as hydrofluorocarbons (HFCs) and hydrofluoroolefins (HFOs), are non-flammable, enhancing safety in their use.

- Regulatory Compliance:

- Modern refrigerants are developed to comply with environmental regulations. For example, the phase-out of ozone-depleting substances like chlorofluorocarbons (CFCs) and the focus on low-global-warming-potential refrigerants align with international agreements.

- Energy Efficiency:

- The selection of appropriate refrigerants can contribute to the overall energy efficiency of cooling systems, reducing energy consumption and operating costs.

It’s important to note that while refrigerants offer numerous advantages, there are also environmental considerations. Some refrigerants, particularly those with high global warming potential, can contribute to climate change. Therefore, there is ongoing research and development to identify and adopt environmentally friendly alternatives with lower environmental impact.

Disadvantages of Refrigerants?

While refrigerants are essential for cooling and air conditioning systems, they also have certain disadvantages, particularly in terms of environmental impact and safety.

Here are some of the main disadvantages associated with traditional refrigerants:

- Ozone Depletion:

- Chlorofluorocarbons (CFCs) and some hydrochlorofluorocarbons (HCFCs) have been found to contribute to the depletion of the ozone layer in the stratosphere. Ozone depletion allows more harmful ultraviolet (UV) radiation from the sun to reach the Earth’s surface.

- Global Warming Potential (GWP):

- Some refrigerants, such as hydrofluorocarbons (HFCs), hydrochlorofluorocarbons (HCFCs), and certain hydrofluoroolefins (HFOs), have high global warming potential. They can trap heat in the atmosphere and contribute to climate change.

- Environmental Impact:

- The production, use, and release of refrigerants into the atmosphere can have negative environmental effects, particularly when they are not handled properly. This includes the potential for groundwater and soil contamination in case of leaks or improper disposal.

- Flammability and Toxicity (for some types):

- Certain refrigerants, such as hydrocarbons (e.g., propane, isobutane), are flammable. Safety measures must be implemented to prevent accidents. Additionally, some refrigerants can be toxic if inhaled or exposed to in large quantities.

- Energy Consumption in Production:

- The manufacturing processes for some refrigerants can be energy-intensive, contributing to overall energy consumption and environmental impact.

- Complexity of Recycling and Disposal:

- The proper recycling and disposal of refrigerants can be complex and costly. If not handled appropriately, refrigerants can contribute to environmental pollution.

- Regulatory Challenges:

- Frequent changes in environmental regulations and international agreements related to refrigerants can pose challenges for industries in terms of compliance and transitioning to new technologies.

- Cost:

- Some environmentally friendly refrigerants, such as those with low GWP, may be more expensive than traditional refrigerants, affecting the initial cost of equipment and systems.

- Limited Availability of Low-GWP Alternatives:

- While efforts are being made to develop low-GWP alternatives, the availability and suitability of these alternatives may vary for different applications, limiting choices in some cases.

- Risk of Leaks:

- Refrigerant leaks, whether during operation or due to system malfunctions, can contribute to environmental problems and may pose safety risks.

In response to these disadvantages, there has been a push toward the development and adoption of environmentally friendly refrigerants with lower ozone depletion potential and GWP. This includes the use of natural refrigerants and synthetic alternatives that have less impact on the environment.

How Refrigerants Work?

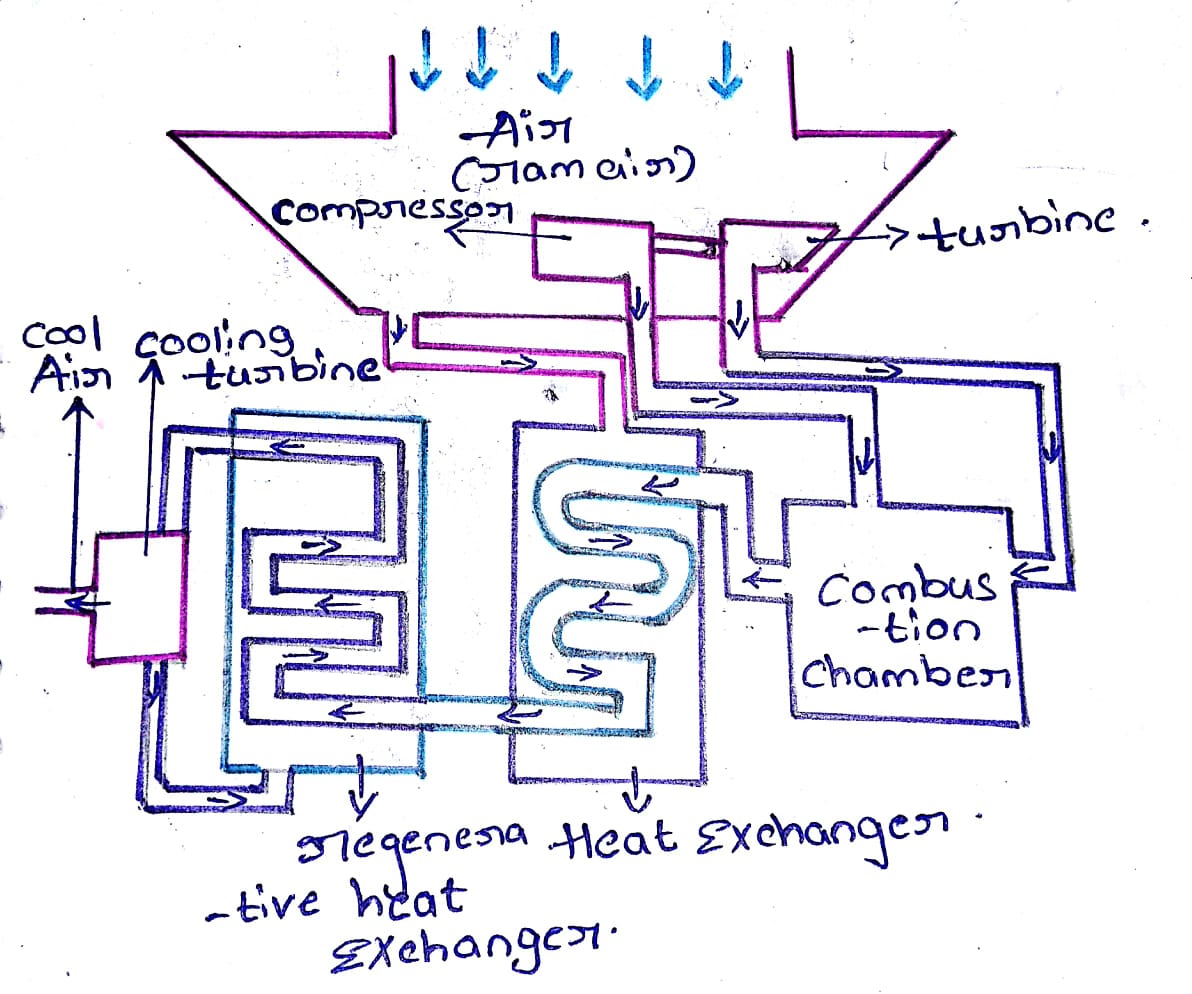

Refrigerants play a crucial role in the operation of refrigeration and air conditioning systems. The basic principle behind how refrigerants work is based on the laws of thermodynamics, specifically the principles of heat transfer. The refrigeration cycle involves the absorption and release of heat, and it typically comprises four main processes: compression, condensation, expansion, and evaporation.

Here’s a step-by-step explanation of how refrigerants work in a typical vapor compression refrigeration system:

- Compression:

- The refrigeration cycle begins with the compressor. The compressor pressurizes the low-pressure, low-temperature gaseous refrigerant vapor, causing it to become a high-pressure, high-temperature gas.

- As the refrigerant is compressed, its temperature and pressure increase.

- Condensation:

- The high-pressure, high-temperature refrigerant vapor then flows to the condenser coil or unit, typically located outside the cooled space.

- In the condenser, the refrigerant releases heat to the surrounding air or a water source, causing it to condense into a high-pressure liquid.

- This process is exothermic, meaning heat is expelled during the phase change from gas to liquid.

- Expansion:

- The high-pressure liquid refrigerant flows through an expansion valve or device, causing a rapid drop in pressure.

- As the pressure decreases, the refrigerant undergoes a phase change from a high-pressure liquid to a low-pressure, low-temperature liquid-gas mixture.

- Evaporation:

- The low-pressure, low-temperature refrigerant vapor now enters the evaporator coil or unit, which is typically located inside the space to be cooled.

- In the evaporator, the refrigerant absorbs heat from the surroundings (air, water, or products to be cooled), causing it to evaporate and turn back into a low-pressure gas.

- This process is endothermic, meaning heat is absorbed during the phase change from liquid to gas.

- Return to the Compressor:

- The low-pressure refrigerant vapor returns to the compressor, and the cycle repeats.

The continuous cycle of compression, condensation, expansion, and evaporation allows the refrigerant to absorb heat from the space to be cooled (evaporator) and release it to the external environment (condenser). This heat transfer process results in the cooling effect inside the space.

It’s important to note that the choice of refrigerant and the design of the refrigeration system impact efficiency, environmental impact, and safety. Advances in refrigerant technology aim to improve energy efficiency and reduce the environmental footprint of refrigeration and air conditioning systems.

Frequently Asked Questions – FAQs

-

What role do refrigerants play in addressing climate change?

Refrigerants impact climate change due to their GWP. The transition to low-GWP and natural refrigerants is a key strategy to mitigate the environmental impact of cooling systems and address climate change concerns.

-

Are there regulations governing the use of refrigerants?

Yes, international agreements and regulations, such as the Montreal Protocol, aim to regulate the production and consumption of substances that deplete the ozone layer. Additionally, regional regulations address the use of refrigerants with high GWP.

-

How does the phase-out of certain refrigerants impact existing systems?

The phase-out of ozone-depleting and high-GWP refrigerants may require retrofitting or replacing existing systems with alternatives. This transition aims to align with environmental regulations and reduce the environmental impact of cooling technologies.

-

What safety considerations are associated with certain types of refrigerants?

Some refrigerants, especially hydrocarbons, are flammable. Safety measures, proper handling, and adherence to regulations are essential to prevent accidents. Additionally, some refrigerants can be toxic, requiring precautions in their use.

-

How does refrigerant choice affect energy efficiency in cooling systems?

The choice of refrigerant significantly influences the energy efficiency of a cooling system. Modern refrigerants are designed to enhance energy efficiency, reducing energy consumption and operating costs.

-

What are natural refrigerants, and why are they gaining popularity?

Natural refrigerants, such as ammonia, CO2, and hydrocarbons, have zero or very low ODP and GWP. They are gaining popularity due to their environmentally friendly characteristics and compliance with sustainable practices.

-

How are refrigerants classified based on their environmental impact?

Refrigerants are classified based on their ozone depletion potential (ODP) and global warming potential (GWP). ODP measures their impact on the ozone layer, while GWP assesses their contribution to global warming over time.

-

What are the environmental concerns associated with refrigerants?

Some refrigerants, like CFCs and HFCs, have been linked to ozone depletion and climate change due to their ozone depletion potential (ODP) and global warming potential (GWP). Efforts are underway to phase out or replace these substances with environmentally friendly alternatives.

-

Why is there a need for different types of refrigerants?

Different refrigerants are developed to meet specific requirements such as efficiency, safety, and environmental impact. Varieties include traditional CFCs, HFCs, natural refrigerants like ammonia and CO2, and newer alternatives with lower global warming potential.

-

What is a refrigerant, and how does it work in cooling systems?

A refrigerant is a substance used in cooling systems to absorb and release heat, facilitating the transfer of thermal energy. It undergoes a continuous cycle of compression, condensation, expansion, and evaporation to cool spaces or products.