Introduction: Keeping the temperature of fuel at a controlled level is one of the most important functions an engine must perform. That’s why having a fuel cooler is so important. Fuel coolers are designed to regulate the flow of liquid between two points and also act as a reservoir for cooling liquids like gasoline. Let’s explore why these components are necessary and how they help keep engines running at peak performance levels.

What is Fuel Coolers in Engines?

Fuel coolers in engines are devices used to cool the fuel before it is injected into the combustion chamber. They help to keep the fuel at a specific temperature range for optimal performance and prevent fuel vaporization that can cause engine issues.

The main reason for using a fuel cooler is to reduce the temperature of the fuel, which can increase the density and viscosity of the fuel, allowing for more precise control of the fuel injection, as well as improving combustion efficiency, power output, and reducing emissions. Fuel coolers can also help to prevent fuel from vaporizing, which can cause engine issues such as misfires and poor performance.

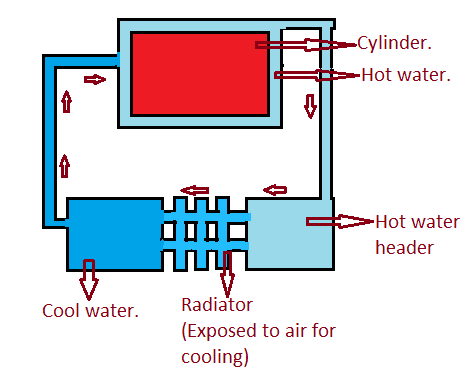

Fuel coolers typically consist of a heat exchanger, which is a device that transfers heat from one fluid to another, and a cooling system, which is used to cool the fuel. The heat exchanger may use the engine’s coolant or air as the cooling medium. The cooling system can be a liquid-based system, such as an air-to-water or water-to-water system, or an air-based system, such as an air-to-air system.

Fuel coolers are used in a variety of engines, including diesel and gasoline engines, and are especially beneficial in high-performance engines, where high fuel pressure is used and fuel temperatures tend to be higher. They are also used in engines that operate in hot environments, such as desert or tropical areas, as well as in engines that are used for heavy-duty applications, such as trucks, buses and other commercial vehicles.

How Does Fuel Coolers in Engine Work?

A fuel cooler works by using a heat exchanger to reduce the temperature of the fuel within an engine’s specified range. Heat exchangers contain channels for circulating air and liquid, which helps to transfer heat from one system to another. In this case, it helps keep fuel from becoming too hot and vaporizing or boiling due to heat buildup. This ensures that the engine can run as efficiently as possible without any issues due to overheated fuel.

Why Fuel Coolers in Engine is Important?

The importance of having a fuel cooler cannot be overstated because it helps protect the engine from potential damage caused by extremely hot temperatures. Without it, there would be no way to regulate the temperature of fuel entering into the engine, which could lead to dangerous conditions if not addressed properly. Furthermore, having a fuel cooler can also improve fuel economy since less energy will be wasted during combustion due to improved efficiency with cooled fuels.

Why do you need a fuel cooler?

Fuel coolers are used in engines for a few key reasons:

- Improve Fuel Density and Viscosity: Fuel coolers help to reduce the temperature of the fuel, which can increase the density and viscosity of the fuel. This can help to improve the accuracy of the fuel injection, and can improve combustion efficiency, leading to better engine performance and fuel economy.

- Reduce Vaporization: High temperatures can cause fuel to vaporize, which can cause engine issues such as misfires, poor performance, and increased emissions. Fuel coolers help to reduce fuel temperature, which can prevent vaporization and ensure that the fuel reaches the engine in a liquid state.

- Optimize Performance: Fuel coolers are especially beneficial in high-performance engines, where high fuel pressure is used, and fuel temperatures tend to be higher. By reducing fuel temperature, fuel coolers can help to optimize engine performance and increase power output.

- Enhanced Engine Durability: Running engine at high temperature and fuel vaporization can cause damage to the engine and its components. Fuel coolers can prevent these damages by maintaining the fuel at the optimal temperature range, this increases engine durability and reduces the chances of breakdowns.

- Compliance with regulations: The emissions from engines are closely regulated, and a Fuel cooler can help in reducing emissions by improving the combustion efficiency and keeping the fuel in a specific temperature range. This can help to comply with emissions regulations, and avoid penalties for non-compliance.

Overall, a fuel cooler plays a vital role in maintaining the optimal temperature of the fuel and in improving the engine performance and durability. It is an important component of the engine system, especially in high-performance, heavy-duty and hot-environment applications.

What does a fuel cooler do on a diesel?

A fuel cooler on a diesel engine performs the same function as on a gasoline engine, that is to cool the fuel before it is injected into the combustion chamber.

Diesel engines rely on the heat of compression rather than a spark to ignite the fuel, so fuel temperature is an important consideration. High fuel temperature can cause vaporization, which can cause issues such as misfires, poor performance and increased emissions.

A fuel cooler on a diesel engine helps to reduce the temperature of the fuel, which can increase the density and viscosity of the fuel, allowing for more precise control of the fuel injection and thus improving combustion efficiency, power output and reducing emissions.

Additionally, diesel engines are known for generating high temperatures in the combustion chamber due to the higher compression ratio than gasoline engine, by removing some of the heat from the fuel with a cooler, it can help to prevent damage to engine components and improve durability.

A fuel cooler also help in keeping the fuel temperature in a specific range, this can help to comply with emissions regulations, as well as to improve the engine performance and durability in high-performance, heavy-duty and hot-environment applications.

Conclusion:

Fuel coolers are essential components that help ensure engines stay running at peak performance levels while protecting them from potential damage caused by extreme temperatures. They work by using a heat exchanger to reduce the temperature of the fuel within an engine’s specified range, allowing for improved efficiency and better overall performance when compared with non-cooled fuels. If you have any questions about whether your vehicle needs a fuel cooler or other components related to its performance, contact your local car mechanic or consult your vehicle’s manual for more information.