What is Calorific Value of Fuel?

Calorific value, also known as heating value or energy content, is a measure of the energy released during the combustion of a substance. It quantifies the amount of heat energy produced per unit of the substance. Calorific value is typically expressed in units like joules per kilogram (J/kg) or British thermal units per pound (BTU/lb).

There are two main types of calorific values:

- Higher Calorific Value (HCV) or Gross Calorific Value (GCV):

- This value includes the heat released when the water vapor produced during combustion is in a liquid state. It accounts for the total energy released, including the latent heat of vaporization of water.

- Lower Calorific Value (LCV) or Net Calorific Value (NCV):

- This value excludes the latent heat of vaporization of water, considering that the water vapor produced during combustion is in a gaseous state. It represents the net energy available for use after condensation of water vapor.

The calorific value of a fuel is a crucial parameter for assessing its energy content and efficiency. Different fuels have different calorific values based on their chemical composition.

Here are approximate calorific values for some common fuels:

- Coal: The calorific value of coal varies depending on its type and grade. Bituminous coal, for example, has a higher calorific value than sub-bituminous or lignite coal. It can range from about 24 to 35 megajoules per kilogram (MJ/kg).

- Natural Gas: Natural gas has a calorific value that can vary, but it is typically around 45 to 55 megajoules per cubic meter (MJ/m³) or 1,000 to 1,200 BTU per cubic foot.

- Gasoline: The calorific value of gasoline is approximately 44 megajoules per liter (MJ/L) or 32 MJ/kg.

- Diesel: The calorific value of diesel fuel is roughly 35 megajoules per liter (MJ/L) or 45 MJ/kg.

- Wood: The calorific value of wood can vary based on its type and moisture content. Dry wood typically has a calorific value in the range of 15 to 20 megajoules per kilogram (MJ/kg).

It’s important to note that these values are approximate and can vary based on factors such as the specific composition of the fuel and its moisture content. Calorific value is a key factor in determining the energy efficiency and performance of combustion-based systems, including power plants and engines.

What is Higher Calorific Value?

Higher Calorific Value (HCV), also known as Gross Calorific Value (GCV), is a measure of the total energy released when a unit mass of a substance is completely combusted. It includes the heat released during combustion and the latent heat of vaporization of water produced by the combustion process. The term “higher” in Higher Calorific Value indicates that it accounts for the total energy, including the energy required to condense the water vapor produced during combustion.

The Higher Calorific Value is expressed in units such as joules per kilogram (J/kg) or British thermal units per pound (BTU/lb). It is an important parameter for assessing the energy content and efficiency of various fuels.

The calculation of Higher Calorific Value takes into account the following components:

- Heat of Combustion:

- This is the energy released during the combustion process when a substance reacts with oxygen to produce carbon dioxide, water vapor, and other combustion products. It represents the chemical energy contained in the fuel.

- Latent Heat of Vaporization:

- During combustion, water vapor is produced as a byproduct. The latent heat of vaporization is the energy required to convert this water vapor back into liquid water. The Higher Calorific Value includes this latent heat, assuming that the water vapor is in a liquid state.

Mathematically, the Higher Calorific Value (HCV or GCV) is calculated as follows:

HCV = Heat of Combustion + Latent Heat of Vaporization

The Higher Calorific Value is especially relevant in applications where the water vapor produced during combustion is likely to be condensed, and the released heat can be recovered. It provides a more comprehensive measure of the energy content of a fuel compared to the Lower Calorific Value (LCV) or Net Calorific Value (NCV), which excludes the latent heat of vaporization and considers the water vapor to be in a gaseous state.

In summary, the Higher Calorific Value represents the total energy content of a fuel, including both the heat released during combustion and the energy required to condense the water vapor produced. It is a key parameter for evaluating the efficiency of combustion processes and comparing the energy content of different fuels.

Higher Calorific Value Applications?

The Higher Calorific Value (HCV) of fuels is an important parameter in various applications where the total energy released during combustion, including the latent heat of vaporization of water, is a critical factor. Here are some applications where Higher Calorific Value is particularly relevant:

- Power Generation:

- In power plants, especially those using steam turbines, the condensation of water vapor produced during combustion is a crucial part of the energy conversion process. The Higher Calorific Value is essential for assessing the overall efficiency and energy output of power generation systems.

- Industrial Heating Systems:

- Industries that rely on combustion for heating processes, such as boilers and furnaces, benefit from considering the Higher Calorific Value. The recovered latent heat from the condensation of water vapor can be utilized for additional heating or industrial processes.

- Combined Heat and Power (CHP) Systems:

- CHP systems, also known as cogeneration systems, simultaneously produce electricity and useful heat from the same energy source. The Higher Calorific Value is valuable in evaluating the overall efficiency and energy utilization of CHP systems.

- District Heating Systems:

- District heating systems supply heat to multiple buildings or industrial facilities from a centralized source. The Higher Calorific Value is crucial for optimizing the energy efficiency of such systems, especially when the condensation of water vapor is utilized.

- Steam Generation for Industrial Processes:

- Many industrial processes, such as in the chemical and manufacturing sectors, involve the use of steam for heating and processing. The Higher Calorific Value is relevant in determining the efficiency of steam generation and utilization.

- Boilers and Furnaces:

- In residential, commercial, and industrial heating systems that use boilers or furnaces, the Higher Calorific Value plays a role in assessing the overall performance and energy efficiency of the combustion process.

- Energy Recovery from Biomass:

- Biomass combustion for energy generation can benefit from considering the Higher Calorific Value, especially in applications where the latent heat from water vapor can be recovered.

- Waste-to-Energy Plants:

- Waste materials with high moisture content, such as municipal solid waste, release water vapor during combustion. The Higher Calorific Value is important for optimizing energy recovery in waste-to-energy plants.

- Industrial Kilns and Dryers:

- Industries using kilns and dryers for processes like cement production or drying materials can benefit from considering the Higher Calorific Value when optimizing energy efficiency.

- Thermal Applications in Transportation:

- In certain transportation applications, such as steam locomotives or industrial vehicles using combustion for heat, the Higher Calorific Value is relevant for assessing the energy efficiency of thermal systems.

- Research and Development:

- Researchers and engineers working on the development of new combustion technologies or energy conversion systems use the Higher Calorific Value to evaluate the potential efficiency and performance of their designs.

Understanding the Higher Calorific Value is crucial in applications where the latent heat of vaporization contributes significantly to the overall energy release during combustion. It helps in designing and optimizing systems for efficient energy utilization and heat recovery.

Advantages of Higher Calorific Value

The advantages of Higher Calorific Value (HCV) are associated with the comprehensive assessment of the total energy content released during combustion, including the latent heat of vaporization of water. Here are several advantages of considering Higher Calorific Value:

- More Accurate Energy Content Measurement:

- HCV provides a more accurate measure of the total energy content of a fuel because it includes both the heat of combustion and the latent heat of vaporization of water.

- Optimized Energy Efficiency:

- In applications where water vapor produced during combustion can be condensed and the latent heat recovered, the inclusion of HCV allows for optimizing energy efficiency by capturing additional usable heat.

- Improved Power Generation Efficiency:

- Power plants that utilize steam turbines for electricity generation benefit from considering HCV. Recovering latent heat during condensation can lead to higher overall efficiency in converting thermal energy to electricity.

- Enhanced Cogeneration and Combined Heat and Power (CHP) Systems:

- Systems that simultaneously produce electricity and useful heat, such as CHP or cogeneration systems, benefit from HCV assessments. Recovered latent heat can be utilized for additional heating, enhancing overall energy utilization.

- Increased District Heating Efficiency:

- District heating systems, which supply heat to multiple buildings from a centralized source, can optimize their efficiency by considering HCV. Recovered latent heat can be used to enhance the heating capacity.

- Effective Steam Generation:

- In industrial processes and applications where steam is generated, understanding HCV helps in designing systems that efficiently utilize the heat released during combustion and the latent heat of vaporization.

- Optimized Waste-to-Energy Conversion:

- Waste-to-energy plants that handle waste materials with high moisture content benefit from considering HCV. Recovering latent heat from water vapor contributes to higher overall energy recovery.

- Improved Boiler and Furnace Performance:

- Heating systems, including boilers and furnaces, can optimize their performance by considering HCV. Recovering latent heat improves the overall energy efficiency of the combustion process.

- Enhanced Thermal Applications in Transportation:

- In thermal applications, such as steam locomotives or industrial vehicles using combustion for heat, understanding HCV contributes to optimizing energy efficiency in thermal systems.

- Accurate Assessment of Biomass Energy:

- Biomass combustion, which often involves high moisture content, benefits from considering HCV. Recovering latent heat enhances the overall efficiency of energy conversion from biomass.

- Efficient Utilization of Industrial Kilns and Dryers:

- Industries using kilns and dryers for processes like cement production or material drying can optimize energy efficiency by considering HCV.

- Research and Development for Energy Systems:

- Researchers and engineers working on the development of new combustion technologies or energy conversion systems use HCV for more accurate assessments of potential efficiency and performance.

In summary, the advantages of Higher Calorific Value are most prominent in applications where the latent heat of vaporization of water can be effectively captured and utilized. This comprehensive measure of energy content contributes to the optimization of energy efficiency in various industrial, power generation, and heating applications.

Disadvantages of Higher Calorific Value

While the Higher Calorific Value (HCV) offers advantages in terms of providing a comprehensive measure of the total energy content released during combustion, it is essential to recognize certain disadvantages and considerations associated with HCV:

- Complexity in Real-World Applications:

- Implementing HCV considerations in real-world applications, especially when dealing with complex combustion processes, may introduce additional complexities in system design and operation.

- Dependence on Water Vapor Recovery:

- The advantages of HCV are realized when water vapor produced during combustion can be condensed, and latent heat is recovered. In applications where water vapor cannot be effectively recovered, the benefits of considering HCV may be limited.

- Infrastructure and Cost Challenges:

- Building infrastructure to recover latent heat from water vapor can be expensive. The additional equipment and systems required to capture and utilize latent heat may pose challenges in terms of cost and implementation.

- Variability in Fuel Composition:

- The composition of fuels can vary, and factors such as moisture content can impact the effectiveness of recovering latent heat. Variability in fuel composition may limit the consistent application of HCV considerations.

- Specific to Certain Applications:

- The advantages of HCV are more pronounced in applications where water vapor can be effectively condensed. In situations where this is not feasible, such as some mobile combustion systems, the benefits may be limited.

- Limited Impact in Dry Fuel Combustion:

- For dry fuels with low moisture content, the contribution of latent heat from water vapor is minimal. In such cases, the benefits of considering HCV may not be as significant.

- Potential for Corrosion and Fouling:

- Condensing water vapor in combustion systems may lead to issues such as corrosion and fouling. The presence of condensed water can be problematic for certain materials and components, requiring additional considerations for system maintenance.

- Environmental Impact:

- The environmental impact of condensing water vapor, such as the release of acidic condensate, should be carefully managed to avoid negative consequences, including environmental pollution.

- Complexity in Control Systems:

- Implementing systems to control the recovery of latent heat can add complexity to control systems, requiring sophisticated monitoring and management.

- Energy Input for Water Vapor Recovery:

- The energy input required to recover latent heat by condensing water vapor should be considered. In some cases, the energy required for recovery may offset the benefits gained from utilizing latent heat.

It’s important to weigh the advantages and disadvantages of considering Higher Calorific Value based on the specific requirements and conditions of the application. While HCV provides a more comprehensive measure of energy content, practical considerations and the feasibility of water vapor recovery play a crucial role in determining its applicability and effectiveness.

What are the applications of the Calorific Value of fuel?

The calorific value of a fuel is a measure of the amount of energy released per unit mass or volume of the fuel when it undergoes combustion. This property is crucial in various applications and industries. Here are some of the key applications of the calorific value of fuel:

- Energy Production and Power Generation:

- Calorific value is essential in determining the energy content of different fuels used in power plants, such as coal, natural gas, oil, and biomass.

- Power plants use the calorific value to calculate the efficiency of energy conversion and to optimize combustion processes for maximum energy output.

- Fuel Selection:

- Industries and households use calorific values to choose the most efficient and cost-effective fuels for heating purposes.

- Calorific values help in comparing the energy content of different fuels, aiding in the selection of the most suitable option based on energy requirements and economic considerations.

- Combustion Efficiency:

- Knowing the calorific value is essential for optimizing combustion processes to achieve maximum energy output and minimize emissions.

- It helps in designing and operating combustion systems, such as furnaces and boilers, to ensure efficient and clean burning of fuels.

- Fuel Quality Assessment:

- Calorific value is a key parameter for assessing the quality and performance of fuels. It provides information about the potential energy that can be derived from a specific fuel.

- Fuel quality standards often include specifications for calorific values to ensure consistency and reliability.

- Industrial Processes:

- Various industrial processes, such as metallurgy and cement production, rely on the combustion of fuels. Calorific values are crucial for optimizing these processes for energy efficiency and cost-effectiveness.

- Environmental Impact Assessment:

- Calorific values are considered in environmental impact assessments, especially when evaluating the emissions and environmental consequences of using specific fuels.

- Understanding the energy content helps in predicting the amount of greenhouse gases and pollutants released during combustion.

- Research and Development:

- Researchers and engineers use calorific values in the development of new fuels and alternative energy sources. It is a critical parameter for assessing the feasibility and performance of emerging technologies.

In summary, the calorific value of a fuel is a fundamental parameter that influences decision-making in energy production, fuel selection, combustion processes, and environmental considerations across various industries and applications.

What is Lower Calorific Value?

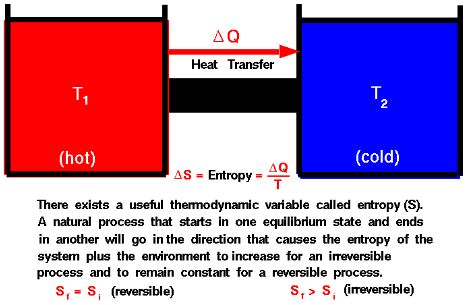

Lower Calorific Value (LCV), also known as Net Calorific Value (NCV), is a measure of the total energy released during the complete combustion of a unit mass of a substance. Unlike Higher Calorific Value (HCV), Lower Calorific Value excludes the latent heat of vaporization of water produced during combustion. The term “lower” indicates that only the sensible heat released during combustion is considered, assuming that the water vapor remains in a gaseous state.

The Lower Calorific Value is expressed in units such as joules per kilogram (J/kg) or British thermal units per pound (BTU/lb). It is an important parameter for assessing the energy content and efficiency of various fuels, especially in applications where water vapor is not condensed, and the latent heat is not recovered.

Mathematically, the Lower Calorific Value (LCV or NCV) is calculated as follows:

LCV=Heat of Combustion

The Lower Calorific Value represents the net energy available for use after the combustion process without considering the energy associated with the latent heat of vaporization. It is particularly relevant in applications where water vapor remains in the gaseous state, and the heat it contains is not recovered.

Here are some key points related to Lower Calorific Value:

- Heat of Combustion:

- LCV focuses on the heat released during the combustion process, which includes the chemical energy contained in the fuel.

- Exclusion of Latent Heat:

- Unlike HCV, LCV excludes the latent heat of vaporization of water. This means that the energy associated with the phase change of water from vapor to liquid is not considered.

- Practical Applications:

- Lower Calorific Value is often used in practical applications, such as in the design and operation of combustion systems, where the recovery of latent heat is not feasible or practical.

- Energy Content Measurement:

- LCV provides a measure of the energy content of a fuel that is directly available for use in a given application.

- Units of Measurement:

- Lower Calorific Value can be expressed in various units, including megajoules per kilogram (MJ/kg) or British thermal units per pound (BTU/lb), depending on regional preferences.

- Comparison with Higher Calorific Value:

- The Lower Calorific Value is generally lower than the Higher Calorific Value because it excludes the latent heat of vaporization.

- Commonly Used in Combustion Calculations:

- In engineering and combustion calculations, the Lower Calorific Value is often used for practical assessments of energy efficiency and performance.

Understanding both the Higher Calorific Value and Lower Calorific Value is important for accurately evaluating the energy content of fuels and optimizing the efficiency of combustion processes based on specific application requirements.

Lower Calorific Value Applications

Lower Calorific Value (LCV) is relevant in various applications where the recovery of latent heat from water vapor produced during combustion is not considered, and the water vapor remains in a gaseous state. Here are some key applications where Lower Calorific Value is particularly significant:

- Combustion Systems without Water Vapor Condensation:

- LCV is commonly used in combustion systems where water vapor is not condensed, and the latent heat is not recovered. This includes applications like certain industrial boilers and furnaces.

- Mobile Combustion Systems:

- In mobile combustion systems such as internal combustion engines in vehicles, water vapor is typically released into the atmosphere without condensation. LCV is relevant in assessing the energy content of fuels in these applications.

- Gas Turbines:

- Gas turbines often operate with water vapor remaining in a gaseous state. The Lower Calorific Value is used to evaluate the efficiency and performance of gas turbine systems.

- Certain Power Plants:

- Power plants that do not incorporate steam cycles for the condensation of water vapor, such as some gas-fired power plants, may use LCV for energy content calculations.

- Drying Processes:

- Industrial processes that involve drying, where the water vapor is released into the atmosphere without recovery, use LCV for assessing the energy requirements and efficiency of drying systems.

- Certain Heating Systems:

- Certain heating systems, particularly those where water vapor is released directly into the environment without condensation, use LCV for energy content calculations.

- Incineration of Waste:

- Waste incineration processes that release water vapor into the atmosphere without recovering latent heat use LCV for assessing the energy released during combustion.

- Certain Residential and Commercial Heating Systems:

- In heating systems that release water vapor into the atmosphere without condensation, such as some residential and commercial heating systems, LCV is relevant for energy content calculations.

- Open Combustion Systems:

- Open combustion systems, where combustion products are released into the atmosphere without capturing water vapor, use LCV for practical energy content assessments.

- Certain Industrial Processes:

- Industrial processes that involve combustion without water vapor recovery, such as certain metallurgical processes or glass manufacturing, may use LCV for energy content calculations.

- Boilers in Steamless Systems:

- Some industrial boilers that do not incorporate steam cycles for water vapor condensation use LCV for assessing the energy content of the fuel.

- Landfill Gas Utilization:

- Landfill gas, which contains water vapor released during combustion, may be utilized in applications where condensation is not feasible, and LCV is used for energy content calculations.

It’s important to note that the choice between Higher Calorific Value (HCV) and Lower Calorific Value (LCV) depends on the specific characteristics of the application and whether water vapor recovery is a practical and feasible consideration. While HCV provides a more comprehensive measure, LCV is often more practical for certain combustion systems and processes.

Advantages of Lower Calorific Value

The advantages of Lower Calorific Value (LCV) lie in its practical application in various combustion systems and processes where the recovery of latent heat from water vapor is not considered. Here are some advantages associated with the use of Lower Calorific Value:

- Practical Energy Content Assessment:

- LCV provides a practical and straightforward measure of the energy content of a fuel that is directly available for use in combustion systems.

- Applicability in Open Combustion Systems:

- In open combustion systems where water vapor is released into the atmosphere without condensation, LCV is a relevant parameter for assessing the energy released during combustion.

- Mobile Combustion Systems:

- LCV is particularly applicable to mobile combustion systems, such as internal combustion engines in vehicles, where water vapor is typically released without condensation.

- Gas Turbines:

- Gas turbines often operate with water vapor remaining in a gaseous state. LCV is used to assess the energy content and efficiency of gas turbine systems.

- Boilers without Steam Cycles:

- Industrial boilers that do not incorporate steam cycles for the condensation of water vapor can use LCV for practical energy content calculations.

- Drying Processes:

- In industrial processes involving drying, where water vapor is released into the atmosphere without recovery, LCV is used for assessing the energy requirements and efficiency of drying systems.

- Simplicity in Calculation:

- The calculation of LCV is simpler compared to Higher Calorific Value (HCV) because it does not involve the consideration of latent heat of vaporization.

- Direct Use in Energy Content Metrics:

- LCV is often directly used in energy content metrics and calculations for fuels in combustion processes without the need for additional adjustments.

- Relevance in Waste Incineration:

- In waste incineration processes where water vapor is released into the atmosphere without recovery, LCV is relevant for assessing the energy released during the combustion of waste materials.

- Suitability for Certain Industrial Processes:

- For certain industrial processes that involve combustion without water vapor recovery, such as certain metallurgical processes or glass manufacturing, LCV is a suitable parameter for energy content calculations.

- Ease of Comparison in Open Systems:

- In open combustion systems where water vapor is released, LCV allows for a straightforward comparison of the energy content of different fuels without considering the complexities of water vapor recovery.

- Relevance in Specific Heating Systems:

- Certain heating systems that release water vapor into the atmosphere without condensation can use LCV for practical energy content assessments.

In summary, the advantages of Lower Calorific Value primarily stem from its simplicity, practicality, and direct applicability in combustion systems and processes where water vapor recovery is not implemented. It serves as a valuable parameter for assessing the energy content of fuels in various real-world applications.

Disadvantages of Lower Calorific Value

While Lower Calorific Value (LCV) has its advantages, there are also certain disadvantages associated with its use, particularly in applications where the recovery of latent heat from water vapor is not considered. Here are some disadvantages of Lower Calorific Value:

- Exclusion of Latent Heat:

- The primary disadvantage of LCV is that it excludes the latent heat of vaporization of water produced during combustion. This means that the energy associated with the phase change of water from vapor to liquid is not considered in the energy content measurement.

- Underestimation of Total Energy Content:

- LCV provides a lower measure of the total energy content of a fuel compared to Higher Calorific Value (HCV), which includes the latent heat of vaporization. This can lead to underestimating the potential energy available for use in certain applications.

- Inapplicability in Systems with Water Vapor Condensation:

- LCV is not suitable for applications where water vapor can be effectively condensed, and latent heat can be recovered. In such systems, HCV is more appropriate for a comprehensive assessment of energy content.

- Limited Use in Certain Steam Systems:

- In applications where steam cycles are used for power generation or other processes involving the condensation of water vapor, LCV may not provide an accurate representation of the energy available for conversion.

- Complexities in Fuel Comparison:

- When comparing fuels with different moisture contents or hydrogen content, using LCV alone may not provide a complete picture of their relative energy contents, as it does not account for variations in latent heat.

- Potential for Misleading Efficiency Estimates:

- In some applications, using LCV alone to estimate energy efficiency may lead to misleading conclusions, especially if the application involves the potential for recovering latent heat.

- Environmental Impact Considerations:

- In applications where water vapor is released without condensation, considerations related to the environmental impact of the released water vapor (e.g., as acidic condensate) may need to be addressed separately from energy content assessments.

- Not Accounting for Recoverable Heat:

- LCV does not consider the recoverable heat from water vapor, which may be harnessed in certain systems for additional heating or industrial processes. This can result in missed opportunities for energy recovery.

- Challenges in Certain Industrial Processes:

- For certain industrial processes that involve high moisture content or where latent heat recovery is practical, using LCV alone may not capture the full potential for energy utilization.

- Sensitivity to Fuel Composition:

- LCV calculations can be sensitive to variations in fuel composition, particularly moisture content. The exclusion of latent heat means that the impact of water vapor is not fully accounted for.

- Incompatibility in Certain Energy Systems:

- In energy systems where steam cycles or condensation processes are integral for energy conversion, relying solely on LCV may be incompatible with the system’s requirements.

It’s important to carefully consider the advantages and disadvantages of both Lower Calorific Value and Higher Calorific Value based on the specific characteristics and requirements of the application. The choice between LCV and HCV depends on factors such as the feasibility of water vapor recovery and the accuracy needed in energy content assessments.

Frequently Asked Questions – FAQ’s

How does the Calorific Value of fossil fuels compare to renewable fuels?

Fossil fuels generally have higher Calorific Values compared to most renewable fuels. However, the environmental impact and sustainability of renewable fuels make them attractive alternatives despite lower Calorific Values.

What are the factors influencing the Calorific Value of biomass fuels?

The Calorific Value of biomass is influenced by factors such as moisture content, type of biomass, and combustion conditions. Drying biomass before combustion can enhance its Calorific Value.

Can Calorific Value be used to compare the energy content of different types of fuels?

Yes, Calorific Value is a valuable metric for comparing the energy content of various fuels. It allows for informed decisions when selecting fuels for specific applications.

How does Calorific Value impact the efficiency of power generation in thermal power plants?

The Calorific Value of the fuel used in thermal power plants directly affects the efficiency of power generation. Higher Calorific Value fuels result in more energy output for a given amount of fuel.

How does the Calorific Value of solid fuels differ from liquid and gaseous fuels?

Solid, liquid, and gaseous fuels have different Calorific Values due to variations in their chemical compositions. Solid fuels, such as coal, generally have higher energy density than liquid and gaseous fuels.

Why is it essential to consider the moisture content of a fuel when calculating Calorific Value?

The moisture content affects the energy content of a fuel. High moisture content reduces the effective Calorific Value as energy is used to evaporate water during combustion.

What role does the carbon-hydrogen ratio play in determining the Calorific Value of hydrocarbon fuels?

The carbon-hydrogen ratio influences the Calorific Value of hydrocarbon fuels. Higher carbon content typically results in a higher Calorific Value, as carbon releases more energy during combustion.

What is the difference between Higher Calorific Value (HCV) and Lower Calorific Value (LCV)?

HCV includes the latent heat of vaporization of water produced during combustion, while LCV excludes it. HCV provides a more comprehensive measure of the total energy released.

How is Calorific Value measured, and what units are used?

Calorific Value is measured using calorimetry, which involves burning a known quantity of fuel and measuring the heat released. Units of Calorific Value include joules per kilogram (J/kg) or British thermal units per pound (BTU/lb).

What is Calorific Value, and why is it important in the context of fuels?

Calorific Value is a measure of the energy content of a fuel, indicating the amount of heat released during its combustion. It is crucial for assessing the efficiency and performance of combustion processes in various applications.