What is Thermodynamic Process in Gases?

A thermodynamic process in gases refers to the transformation of a gas from one state to another, involving changes in temperature, pressure, volume, and internal energy. These processes are governed by the laws of thermodynamics and are essential for understanding and analyzing the behavior of gases in various physical and engineering scenarios. The four main types of thermodynamic processes for gases are isothermal, adiabatic, isobaric, and isochoric.

- Isothermal Process:

- In an isothermal process, the temperature of the gas remains constant throughout the entire transformation. This is achieved by allowing the gas to exchange heat with its surroundings. During an isothermal expansion, for example, the gas absorbs heat, and during compression, it releases heat to maintain a constant temperature.

- Adiabatic Process:

- An adiabatic process is characterized by the absence of heat exchange with the surroundings. In an adiabatic expansion, the gas performs work on its surroundings, causing a decrease in temperature. Conversely, during adiabatic compression, the gas absorbs energy from its surroundings, leading to an increase in temperature.

- Isobaric Process:

- In an isobaric process, the pressure of the gas remains constant while other parameters, such as volume and temperature, change. For example, in an isobaric expansion, the gas performs work on its surroundings, causing an increase in volume while maintaining a constant pressure.

- Isochoric Process (Isovolumetric or Constant Volume):

- In an isochoric process, the volume of the gas remains constant. Since the gas does not change its volume, no work is done, and the heat added or removed directly affects the internal energy and temperature of the gas. This process is often represented by vertical lines on a P-V diagram.

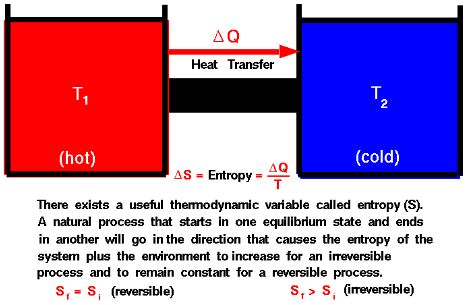

These thermodynamic processes are often represented graphically on pressure-volume (P-V) diagrams or temperature-entropy (T-S) diagrams. The laws of thermodynamics, such as the First Law (conservation of energy) and the Second Law (entropy increase), govern the behavior of gases during these processes.

Understanding thermodynamic processes is essential in various applications, including the design and analysis of heat engines, refrigeration systems, and other devices involving the manipulation of gases for energy conversion.

Key Concepts:

- Equilibrium State:

- A thermodynamic process involves the transition of a gas from one equilibrium state to another. An equilibrium state is a stable condition where macroscopic properties of the gas, such as pressure and temperature, remain constant over time.

- Heat and Work Transfer:

- Thermodynamic processes often include the transfer of energy between the gas and its surroundings. This energy transfer can occur as heat or work. Heat is the energy transfer due to temperature differences, and work is the energy transfer associated with mechanical processes.

- P-V Diagrams:

- Graphical representations, such as Pressure-Volume (P-V) diagrams, are commonly used to visualize and analyze thermodynamic processes. These diagrams provide insights into the work done by or on the gas, as well as changes in its internal energy.

Advantages Thermodynamic Process in Gases

Thermodynamic processes in gases play a crucial role in various scientific and engineering applications, offering several advantages. Here are some of the key advantages of understanding and utilizing thermodynamic processes in gases:

- Energy Conversion:

- Thermodynamic processes provide a framework for understanding and optimizing the conversion of energy between different forms. This is particularly important in the design and analysis of engines, turbines, and other devices that involve the expansion and compression of gases.

- Efficiency Improvement:

- Knowledge of thermodynamic processes allows engineers to design systems with improved efficiency. By optimizing processes such as isentropic expansion or compression, it is possible to enhance the overall efficiency of energy conversion devices.

- Heat Transfer Optimization:

- Understanding thermodynamic processes helps in optimizing heat transfer mechanisms. This is critical in the design of heat exchangers, refrigeration systems, and other devices where efficient heat transfer is essential.

- Environmental Impact Reduction:

- Efficient thermodynamic processes can contribute to the reduction of environmental impact by improving the energy efficiency of various systems. This is particularly relevant in industries where energy consumption and emissions are significant considerations.

- Engine Design and Performance:

- Thermodynamic processes are fundamental to the design and analysis of engines, including internal combustion engines and gas turbines. Engineers use thermodynamics to optimize processes like combustion, expansion, and exhaust to enhance engine performance.

- Refrigeration and Air Conditioning:

- The principles of thermodynamic processes are essential in the design and operation of refrigeration and air conditioning systems. This knowledge allows for the efficient cooling or heating of spaces and substances.

- Power Generation:

- In power generation systems, such as steam and gas power plants, an understanding of thermodynamic processes is crucial for maximizing the conversion of heat into mechanical work. This leads to improved overall power plant efficiency.

- Safety and Reliability:

- Knowledge of thermodynamic processes is important for ensuring the safety and reliability of various systems. Engineers can design systems with appropriate pressure and temperature controls to prevent failures and enhance operational safety.

- Environmental Studies:

- Understanding the thermodynamics of gases is valuable in environmental studies, including the modeling of atmospheric processes. It helps researchers analyze weather patterns, air quality, and the behavior of pollutants in the atmosphere.

- Optimization of Industrial Processes:

- In various industrial processes, such as chemical manufacturing and material processing, thermodynamic principles aid in optimizing conditions for efficiency and cost-effectiveness. This includes the design of reactors, separation processes, and energy recovery systems.

In summary, the advantages of understanding thermodynamic processes in gases extend across diverse fields, impacting the design, efficiency, and environmental considerations of numerous systems and processes. This knowledge is foundational for engineers, scientists, and researchers working in energy, environmental science, and related disciplines.

Disadvantages Thermodynamic Process in Gases

While thermodynamic processes in gases offer numerous advantages, there are also certain challenges and disadvantages associated with their practical implementation. Here are some of the key disadvantages of thermodynamic processes in gases:

- Irreversibility:

- Many real-world thermodynamic processes are inherently irreversible. Idealized theoretical models often assume reversibility, but in practice, factors such as friction, heat dissipation, and irreversibilities lead to efficiency losses.

- Complexity of Real Gases:

- Real gases may deviate from ideal behavior under certain conditions, introducing complexities in the analysis of thermodynamic processes. Correctly modeling the behavior of real gases requires more sophisticated equations of state.

- Limited Idealization:

- Idealizations used in thermodynamic processes, such as assuming ideal gases or perfectly insulated systems, may not always accurately represent real-world conditions. Deviations from ideal behavior can impact the accuracy of predictions.

- Energy Losses:

- Energy losses due to heat transfer to the surroundings or friction can reduce the efficiency of thermodynamic processes. These losses are often unavoidable and contribute to reduced overall system efficiency.

- Limited Control over Processes:

- In certain thermodynamic processes, maintaining strict control over parameters such as temperature, pressure, and volume can be challenging. Variations in external conditions or unexpected disturbances may impact the process.

- Environmental Impact:

- Some thermodynamic processes involve the release of pollutants or greenhouse gases, contributing to environmental impact. For example, combustion processes in engines and power plants release carbon dioxide and other pollutants.

- High Pressures and Temperatures:

- Some applications, particularly those in power generation and high-performance engines, involve operating at high pressures and temperatures. These conditions can lead to increased material wear, corrosion, and the need for specialized materials.

- Need for Cooling Systems:

- Many thermodynamic processes, especially in power generation and industrial applications, generate heat. Effective cooling systems are often required to maintain equipment within safe operating temperatures, adding complexity and cost.

- Complex System Integration:

- Integrating thermodynamic processes into complex systems, such as combined heat and power (CHP) systems, can be challenging. Coordination of various components and optimization of the entire system require careful engineering.

- Resource Intensity:

- Some thermodynamic processes, particularly those involving the extraction and refinement of resources, can be resource-intensive. This includes the extraction of raw materials for the production of energy or materials.

It’s important to note that the disadvantages mentioned above do not negate the fundamental importance and applicability of thermodynamic principles. Rather, they highlight challenges and considerations that engineers and scientists must address when designing and implementing thermodynamic processes in practical applications. Ongoing research and technological advancements aim to mitigate these challenges and improve the efficiency and sustainability of thermodynamic systems.

Frequently Asked Questions – FAQ’s

How can thermodynamic processes be visualized and analyzed?

Thermodynamic processes are visualized and analyzed using diagrams like P-V diagrams and T-S diagrams. These diagrams help engineers and scientists understand the changes in gas properties during different processes and optimize system performance.

What applications benefit from an understanding of thermodynamic processes in gases?

Thermodynamic processes in gases have applications in various fields, including power generation, aerospace engineering, refrigeration, air conditioning, and environmental studies. They play a crucial role in optimizing processes for efficiency and sustainability.

How do thermodynamic processes relate to environmental impact?

Some thermodynamic processes, especially those involving combustion, contribute to environmental impact by releasing pollutants or greenhouse gases. Research focuses on designing processes with reduced environmental footprint and increased sustainability.

What challenges arise in real-world thermodynamic processes?

Real-world thermodynamic processes face challenges such as irreversibility, deviations from ideal behavior in gases, energy losses due to heat dissipation, and complexities introduced by factors like friction. These challenges impact the practical implementation and efficiency of processes.

How do thermodynamic processes contribute to energy efficiency?

Knowledge of thermodynamic processes allows engineers to design systems with improved energy conversion and efficiency. Optimization of processes, heat transfer mechanisms, and pressure-volume relationships helps enhance the overall efficiency of energy conversion devices.

What role do thermodynamic processes play in engine design?

Thermodynamic processes are fundamental to engine design, influencing the efficiency and performance of engines. Understanding processes like combustion, expansion, and compression is essential in optimizing engines for various applications, including internal combustion engines and gas turbines.

How does an isothermal process differ from an adiabatic process?

In an isothermal process, the temperature remains constant, while in an adiabatic process, there is no heat exchange with the surroundings. During an isothermal process, heat is exchanged to maintain a constant temperature, whereas in an adiabatic process, internal energy changes without heat transfer.

What are the different types of thermodynamic processes in gases?

There are four main types of thermodynamic processes in gases: isothermal, adiabatic, isobaric, and isochoric. Isothermal processes maintain constant temperature, adiabatic processes involve no heat exchange, isobaric processes maintain constant pressure, and isochoric processes maintain constant volume.

How are thermodynamic processes represented graphically?

Thermodynamic processes are often represented on graphical diagrams, such as Pressure-Volume (P-V) diagrams or Temperature-Entropy (T-S) diagrams. These diagrams visually depict the changes in key parameters during processes like expansion, compression, heating, or cooling.

What is a thermodynamic process in gases?

A thermodynamic process in gases refers to the transformation of a gas from one equilibrium state to another, involving changes in temperature, pressure, volume, and internal energy. These processes are governed by the laws of thermodynamics and play a crucial role in understanding the behavior of gases in various applications.